Stent and method for manufacturing the same

A frame and component technology, applied in the field of stents and the manufacture of the stents, can solve problems such as reducing elastic force, product quality degradation, and damage to wire components, and achieve the effect of reducing pain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will now be described more fully with reference to the accompanying drawings, in which exemplary embodiments of the invention are shown.

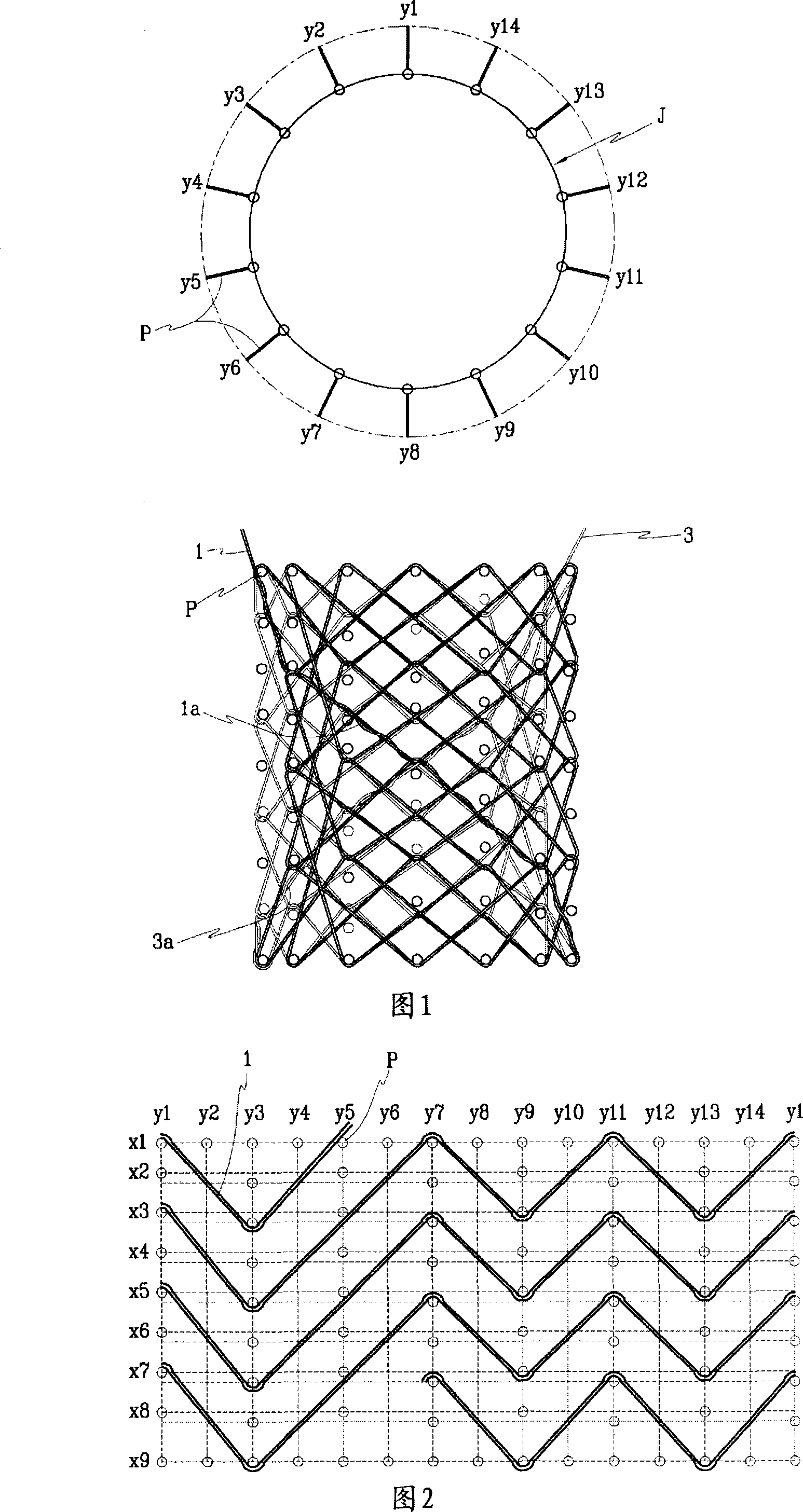

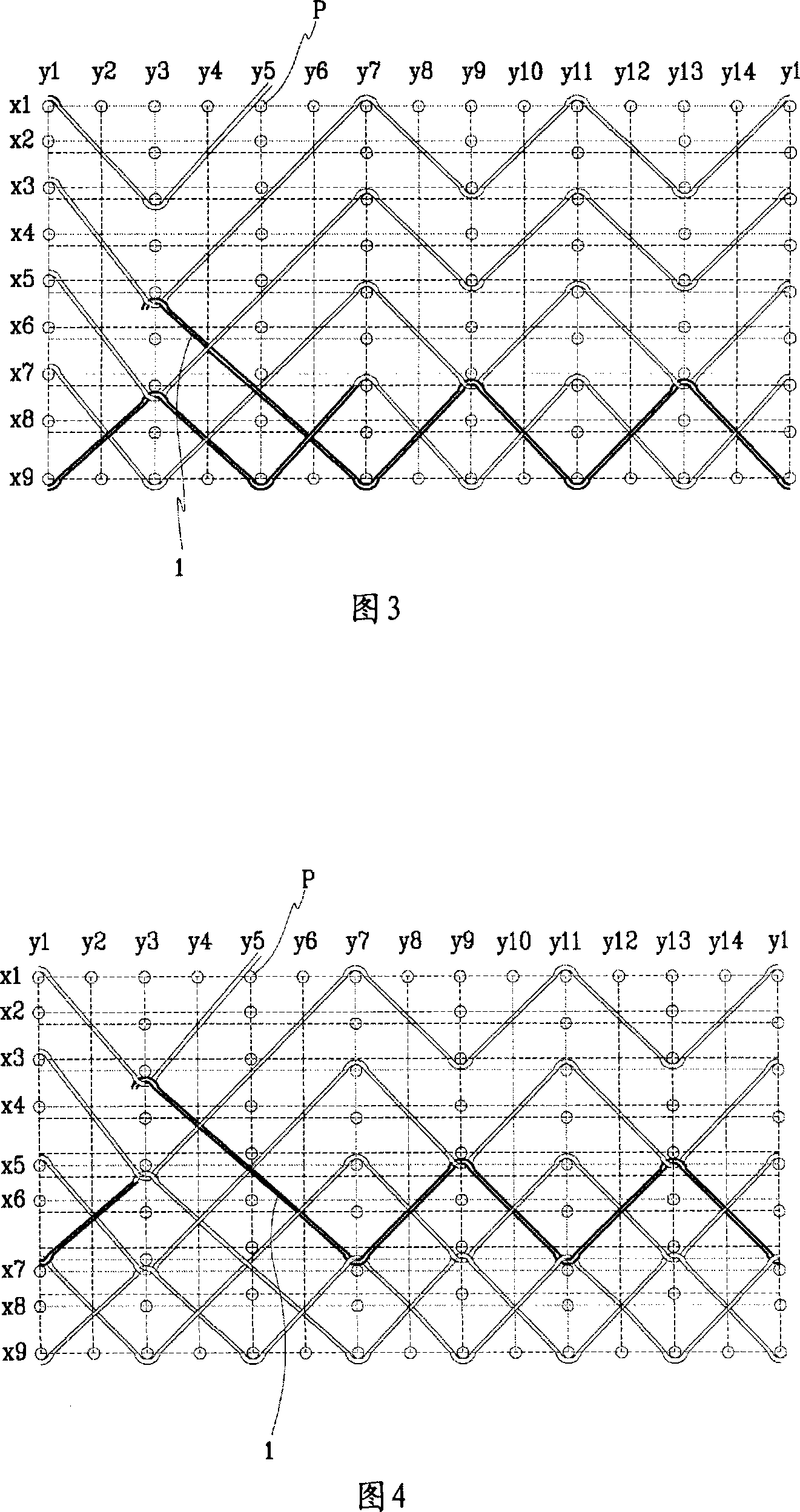

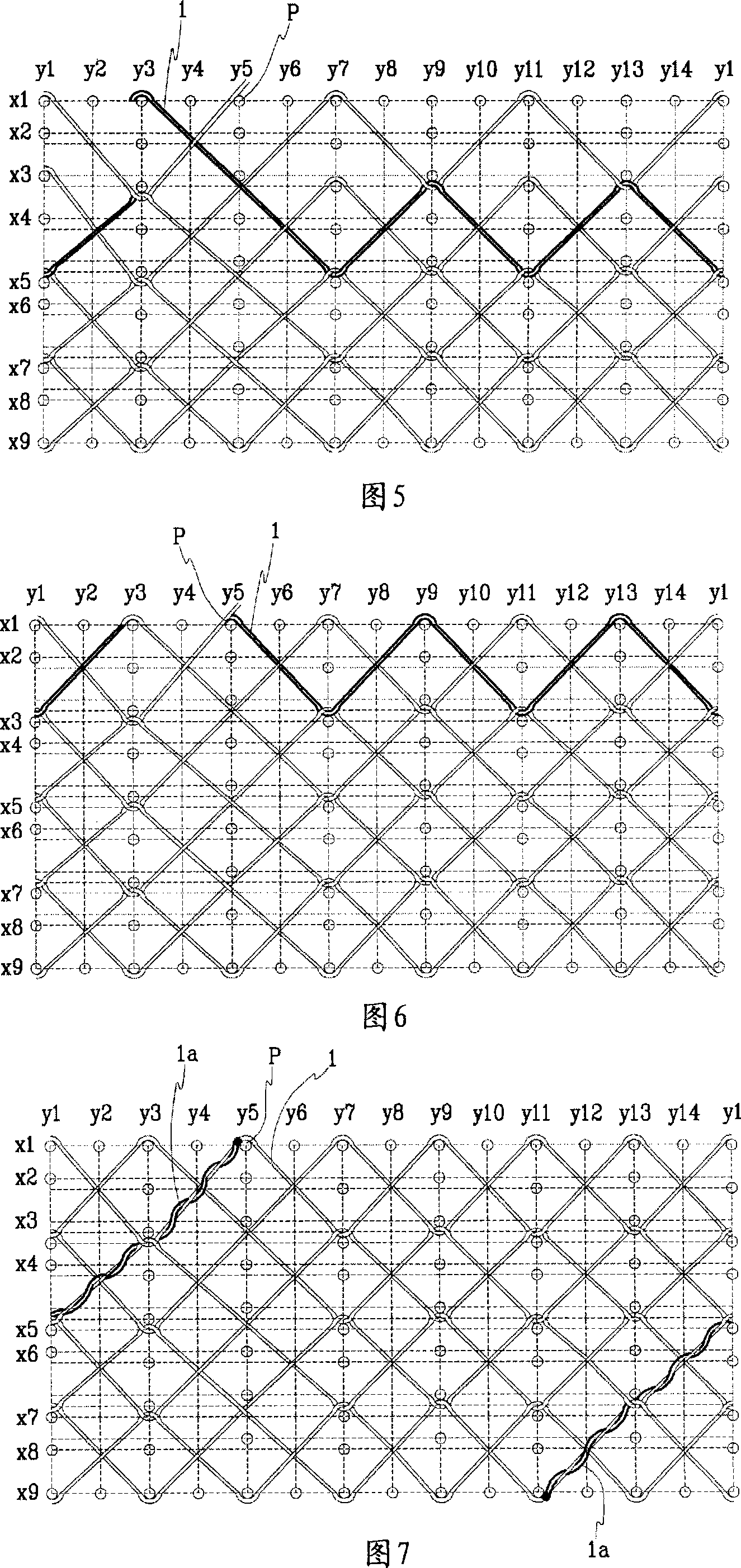

[0025] Figure 1 is a perspective view of a stent made by the method of the present invention. 2 to 14 are views showing a continuous process of manufacturing the stent.

[0026] According to an embodiment of the invention, the bracket is formed by a first member 1 and a second member 3 . 2 to 7 are views showing a process of forming a cylindrical bracket on a manufacturing frame from a first member. 8 to 14 are views illustrating a process of forming a fine mesh structure from the second member. A fine mesh structure is formed on the cylindrical support formed by the first member. The first member 1 and the second member 3 may be formed of wire members, which may be coated for medical use, to be inserted into cavities or lesions of the human body. A method of manufacturing a bracket using the manufacturing f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com