Beam type energy-saving oil pumping machine

An oil pumping unit and beam-type technology, which is applied in the field of energy-saving beam-type oil pumping units, can solve problems such as difficulty in saving energy, and achieve the effect of saving energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

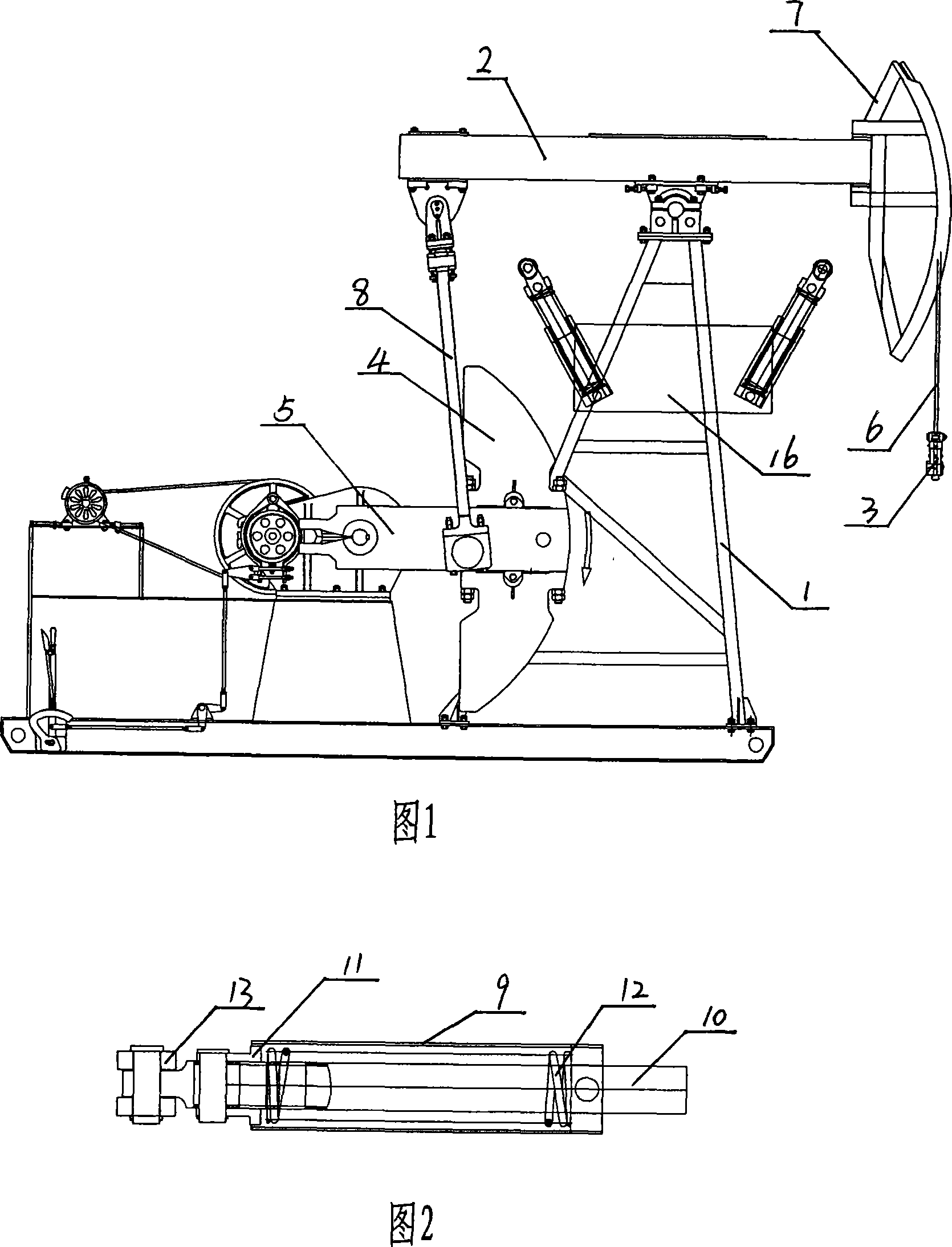

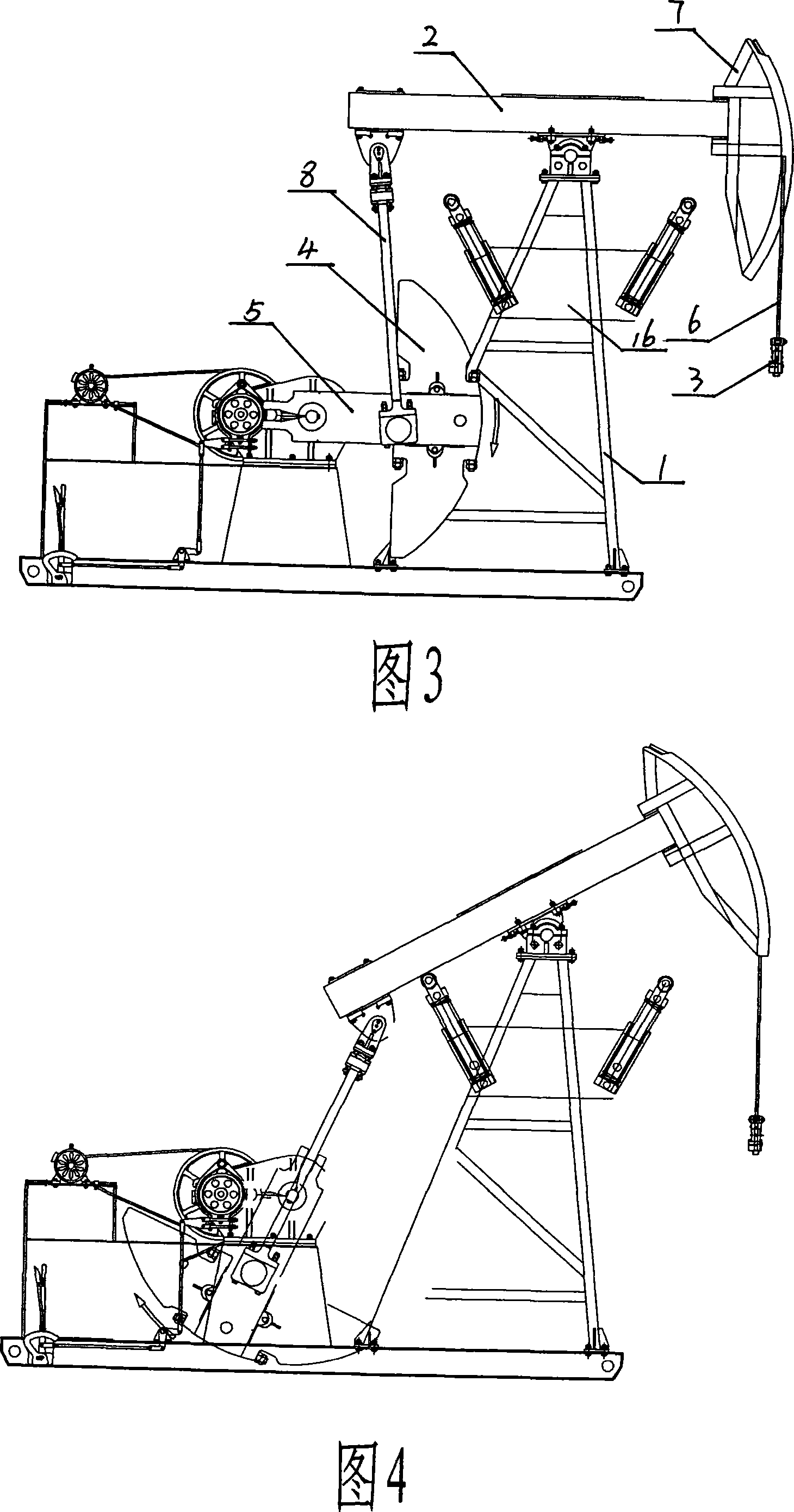

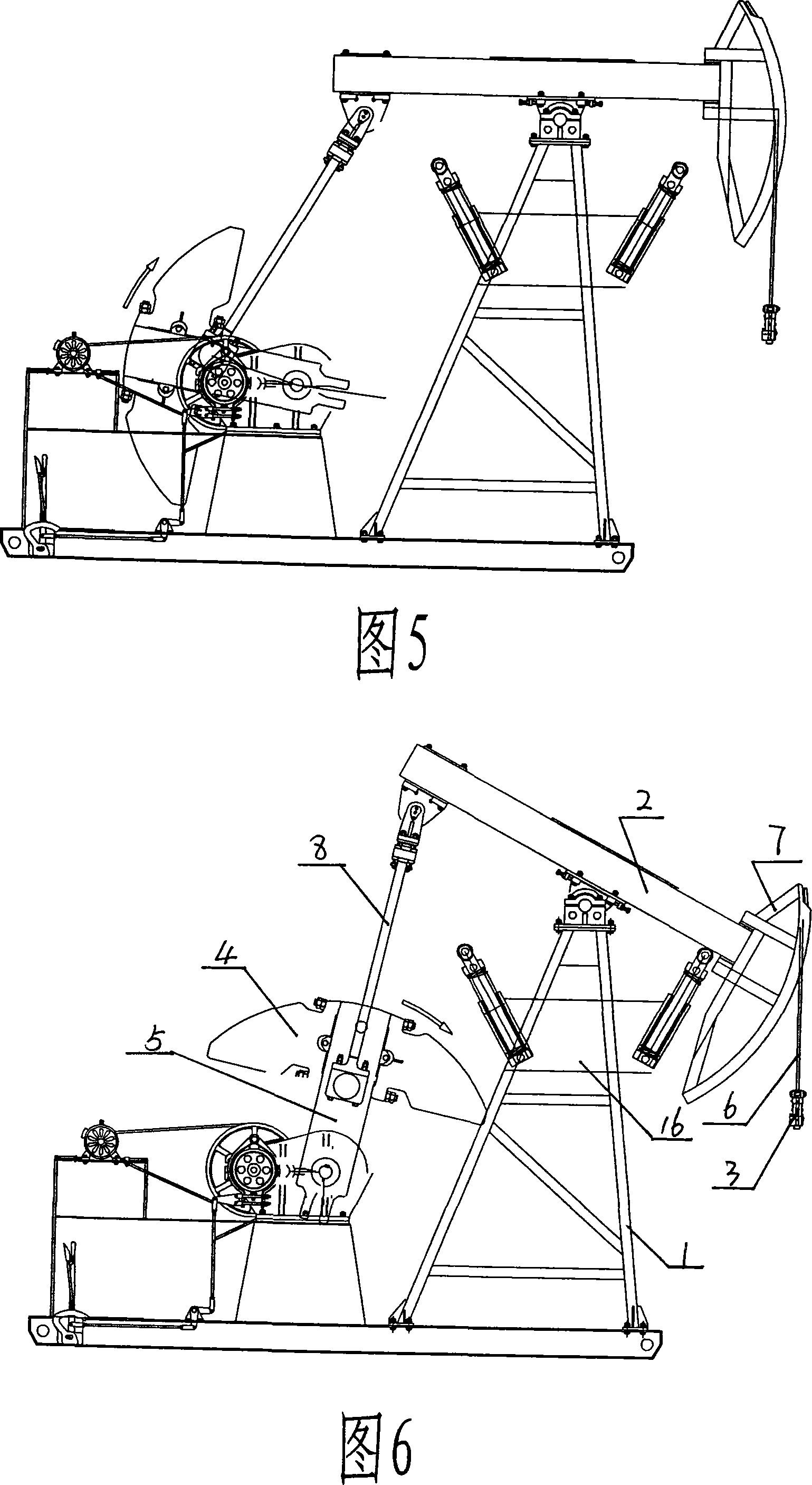

[0021] As shown in Figures 1-6, the beam-type energy-saving pumping unit includes a central support 1, a beam 2 arranged on the top of the central support 1, a pump rod 3, and one end driven and rotated by a motor and a reducer. The crank 5 of the balance weight 4, the end of the beam 2 is fixed with the donkey head 7 connected to the oil pump rod 3 through the steel cable 6, and the other end is connected with the crank 5 through the connecting rod 8, and the energy storage and utilization is arranged under the upstream beam 2 of the central support 1 device, the energy storage and utilization device includes a support body fixed on the central support 1, a support rod 10 supported by the support body and capable of reciprocating relative to the support body in a fixed direction, and an adjustment pressure sleeve is fixed on the support rod 10 11. A spring 12 is set between the adjusting pressure sleeve 11 on the support rod 10 and the supporting fixed body. The supporting fi...

Embodiment 2

[0025] As shown in Figures 7 and 8, the beam-type energy-saving pumping unit includes a central support 1, a beam 2 arranged on the top of the central support 1, an oil pump rod 3, and one end driven by a motor and a reducer is fixed with a The crank 5 of the balance weight 4, the end of the beam 2 is fixed with the donkey head 7 connected to the oil pump rod 3 through the steel cable 6, and the other end is connected with the crank 5 through the connecting rod 8, and the energy storage and utilization is arranged under the upstream beam 2 of the central support 1 device, the energy storage and utilization device includes a support body fixed on the central support 1, a support rod 10 supported by the support body and capable of reciprocating relative to the support body in a fixed direction, and an adjustment pressure sleeve is fixed on the support rod 10 11. A spring 12 is set between the adjusting pressure sleeve 11 on the support rod 10 and the supporting fixed body. Suppo...

Embodiment 3

[0027]As shown in Figures 9 and 10, the beam-type energy-saving pumping unit includes a central support 1, a beam 2 arranged on the top of the central support 1, a pump rod 3, and a balance fixed at one end driven by a motor and a reducer. The crank 5 of the block 4, the donkey head 7 connected to the oil pump rod 3 through the steel cable 6 is fixed at one end of the beam 2, and the other end is connected with the crank 5 through the connecting rod 8, and an energy storage and utilization device is arranged under the upstream beam 2 of the central support 1 The energy storage and utilization device includes a support body fixed on the central support 1, a support rod 10 supported by the support body and capable of reciprocating relative to the support body in a fixed direction, and an adjustment pressure sleeve 11 is fixed on the support rod 10 , A spring 12 is sleeved between the adjusting pressure sleeve 11 on the support rod 10 and the supporting fixed body. The supporting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com