Paper with adhesive

A technology of adhesives and paper sheets, which is applied in the direction of adhesives, film/sheet adhesives, paper, etc., can solve the problems of bending, reduced adhesion, and little improvement in defects, and achieve the goal of suppressing peeling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

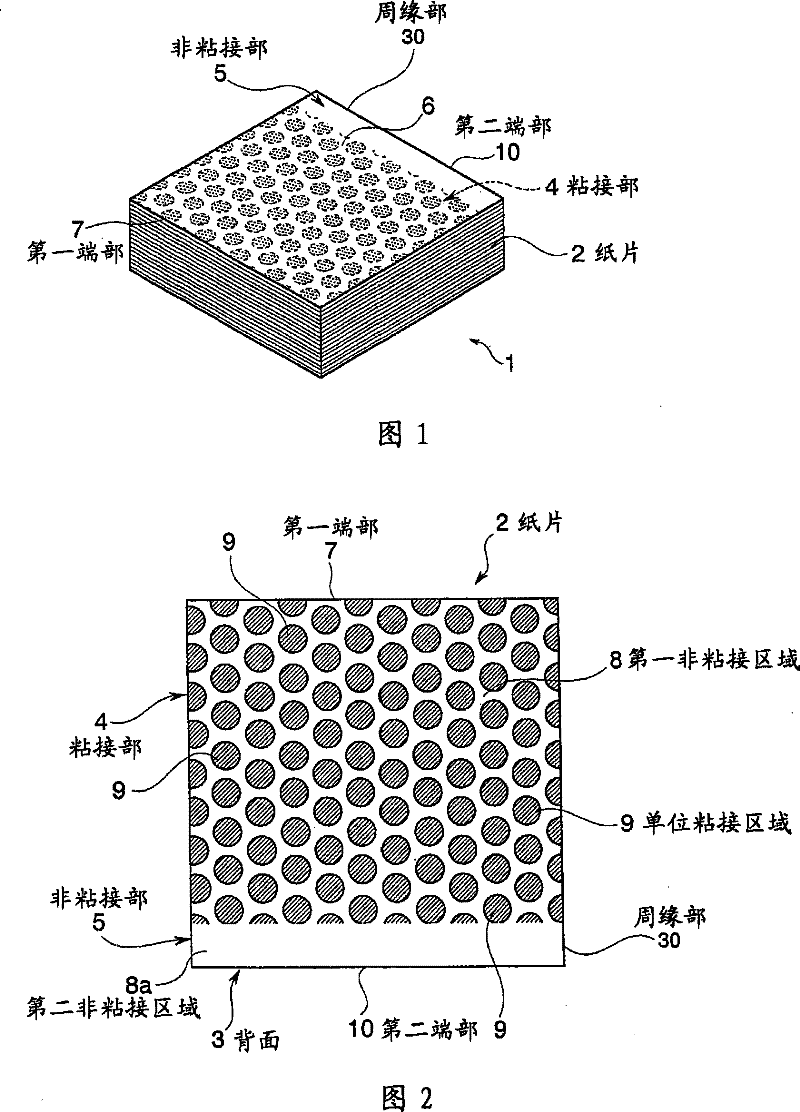

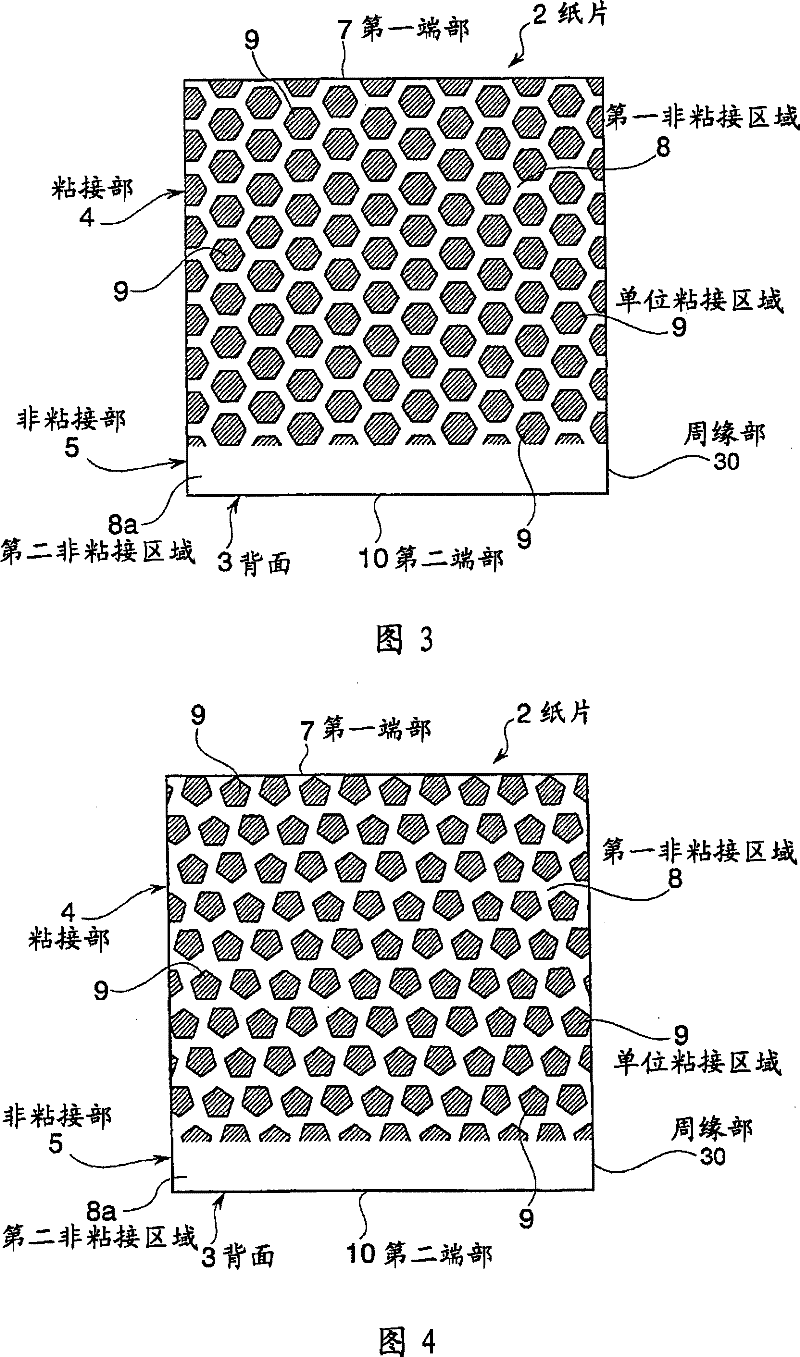

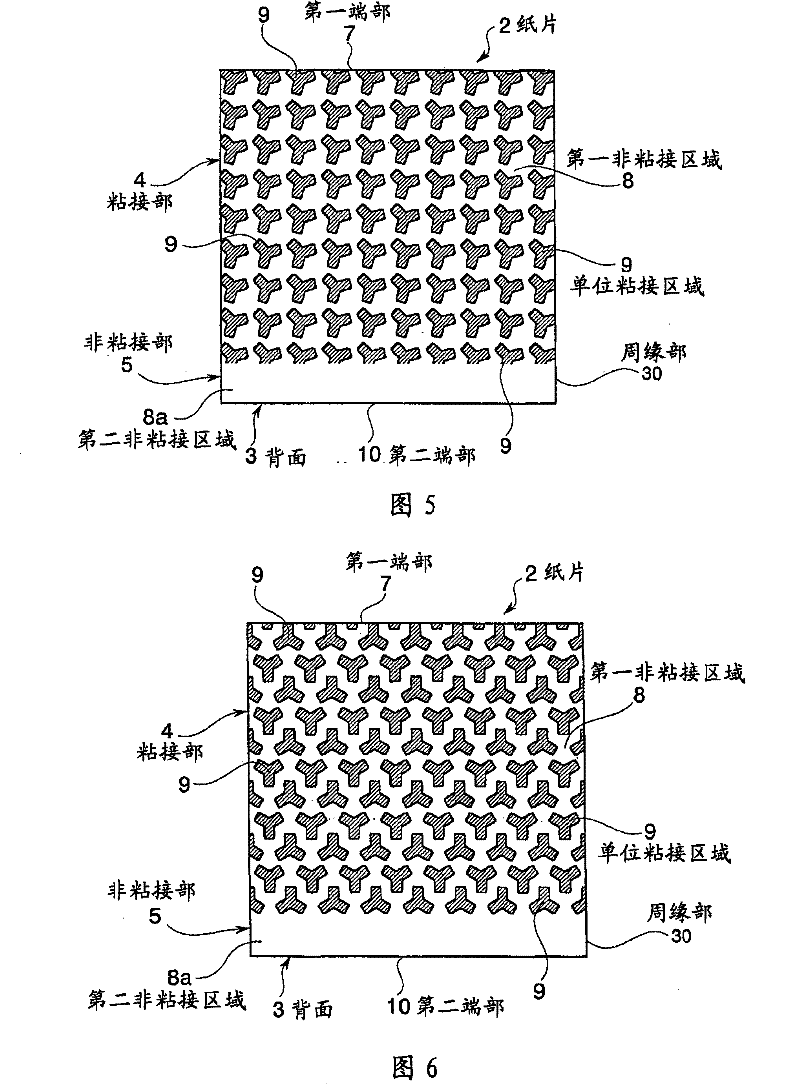

[0052] Note 1 of Example 1, such as figure 1 As shown, it is formed by stacking a plurality of paper sheets with adhesive (hereinafter referred to as paper sheets) 2 having a substantially square shape. The paper sheets 2 are stacked as a note 1, but each paper sheet 2 itself serves as a note when used. In addition, each paper sheet 2 is provided with an adhesive part 4 and a non-adhesive part 5 on the back surface 3 as its one surface, and the surface 6 as the other surface is coated with a coating to make the laminated paper sheets 2 easy to peel off. Floor. The coating treatment itself can be applied to treatments widely known in the field. In addition, it goes without saying that the shape of the paper sheet is not limited to a square.

[0053] The adhesive portion 4 is provided on one side (hereinafter, this side is referred to as "first end portion 7") side of the peripheral edge portion 30 of the back surface 3. In this embodiment 1, the bonding part 4, such as figure ...

Embodiment 2

[0062] The composition of the memo pad 1 of this embodiment 2 is that the unit adhesive area 9 and the net-shaped first non-adhesive area 8 constituting the adhesive portion 4 in the embodiment 1 are maintained in shape but their function is performed replace. In addition, except for the structure of the adhesive portion 4 of the paper sheet 2 used in the second embodiment, it is the same as the first embodiment, and the same reference numerals are used, and detailed description is omitted.

[0063] Specifically, such as Figure 8 As shown, on the back 3 of the paper sheet 2 constituting the memo 1, there are formed: a net-like, adhesive area 21 applied with an adhesive, and provided in the mesh surrounded by the adhesive area 21, the texture is exposed 的Multiple units of non-bonded area 22. That is, the area corresponding to the unit adhesion area 9 in Example 1 becomes the unit non-adhesion area 22, and the area corresponding to the first non-adhesion area 8 becomes the adhesio...

Embodiment 3

[0068] In this embodiment 3, as Picture 9 As shown, in the unit bonding area 9 in the modification 1 of the aforementioned embodiment 1, a non-bonding area 23 in the domain where the texture of the paper sheet 2 is exposed is formed. Specifically, in Modification 1 of Embodiment 1, a hexagonal region similar to the unit bonding region 9 and smaller than the hexagon of the unit bonding region 9 is concentrically formed in the unit bonding region 9 Non-adhesive area 23. In other words, the third embodiment is configured such that the ring-shaped unit bonding regions 9 are arranged at predetermined intervals. Since the adhesive force of the unit adhesive area 9 is reduced, the size of the non-adhesive area 23 in the domain is preferably about 1 / 4 of the unit adhesive area 9, for example.

[0069] According to such a configuration, the unit adhesion regions 9 are more dispersed than the modification 1 of the first embodiment. As a result, the stress generated when the paper sheet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com