Ceramic closet having vacuum shredded paper suction and discharging function

A technology of vacuum suction and toilet, which is applied to flushing equipment with water tanks, sanitary equipment for toilets, water supply devices, etc. It can solve the problem of insufficient shredding of sanitary napkin fibers, unsharp thick blades, and blockage of sewage pipes And other problems, to achieve the effect of good shredding effect, improved working life, and smooth drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in further detail by the following examples.

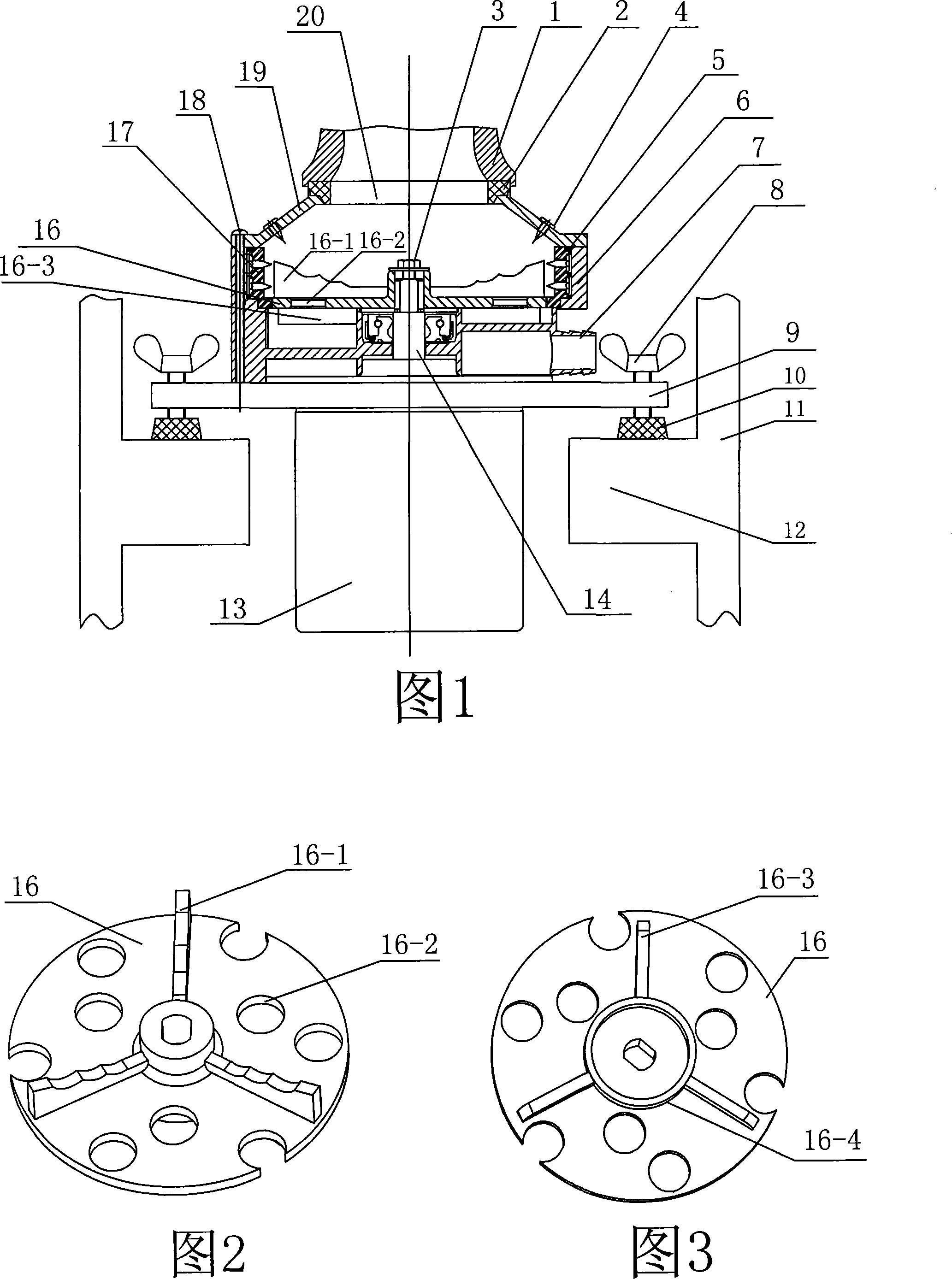

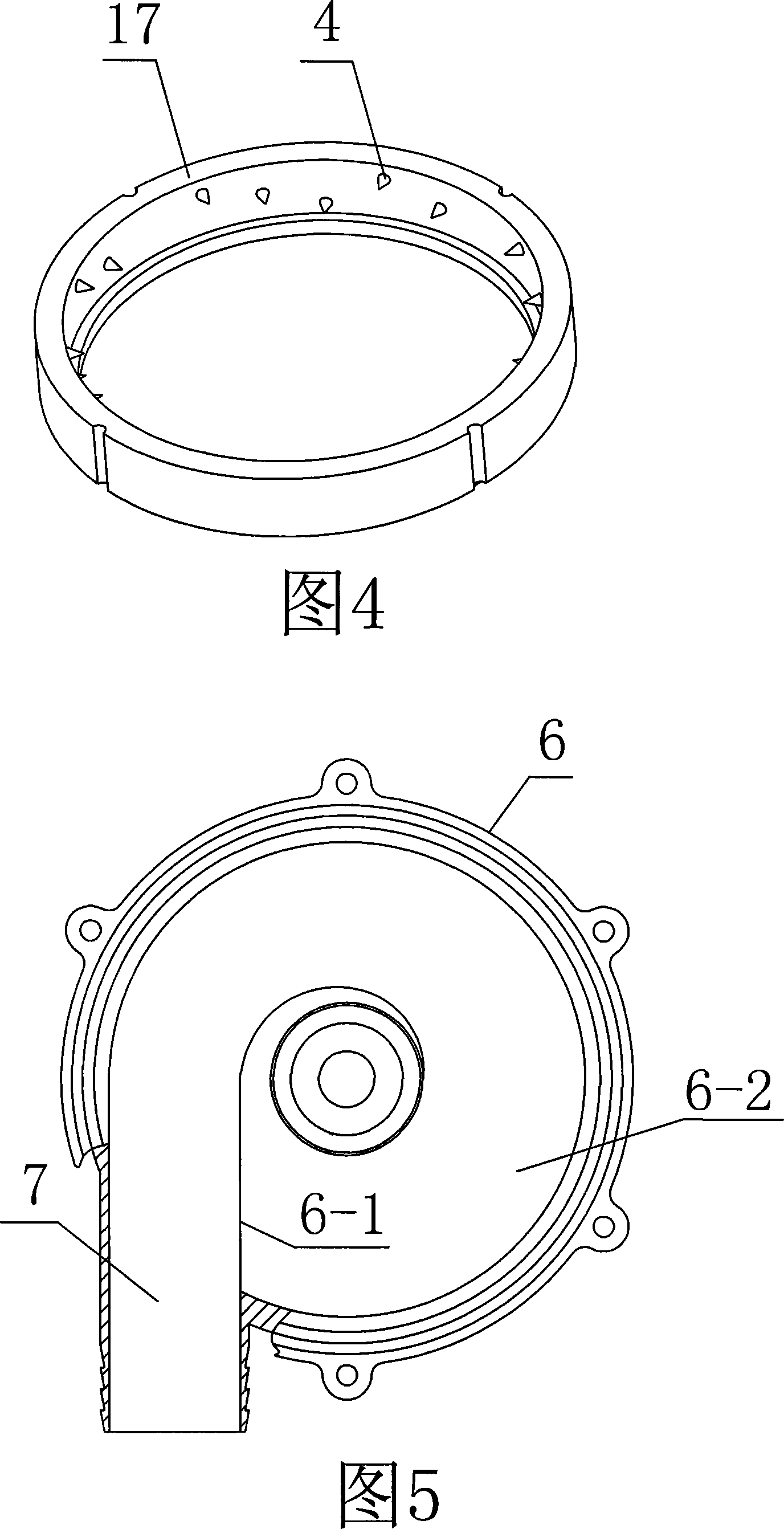

[0019] Referring to Fig. 1, Fig. 2, Fig. 3, Fig. 4, and Fig. 5, a ceramic toilet with the function of vacuum suction and discharge shredding of the present invention is composed of a water tank, a pan, a base 11, a water inlet pipe, The siphon tube 1 and the ceramic support seat 12 are integrally sintered. There is a water inlet pipe connected between the bottom of the water tank and the upper part of the pan. A siphon tube is drawn from the bottom of the pan. There is an upper port slightly below the turning point. The inner diameter of the siphon tube 1 is Φ65mm; a vacuum suction and discharge paper shredder is movably supported on the ceramic support seat 12 under the water tank through the support plate 9, the lifting screw 8, and the shock-absorbing foot 10. The liquid inlet 20 is in sealing connection with the upper port of the siphon 1 . This vacuum suction and discharge paper shre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com