Spillway tunnel whole-section aeration method and spillway tunnel having whole-section aeration structure

A flood tunnel and full-section technology, applied in water conservancy projects, marine engineering, coastline protection, etc., can solve the problems of side wall cavitation damage, endanger the safe operation of engineering dams, etc., and achieve the effect of avoiding cavitation damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

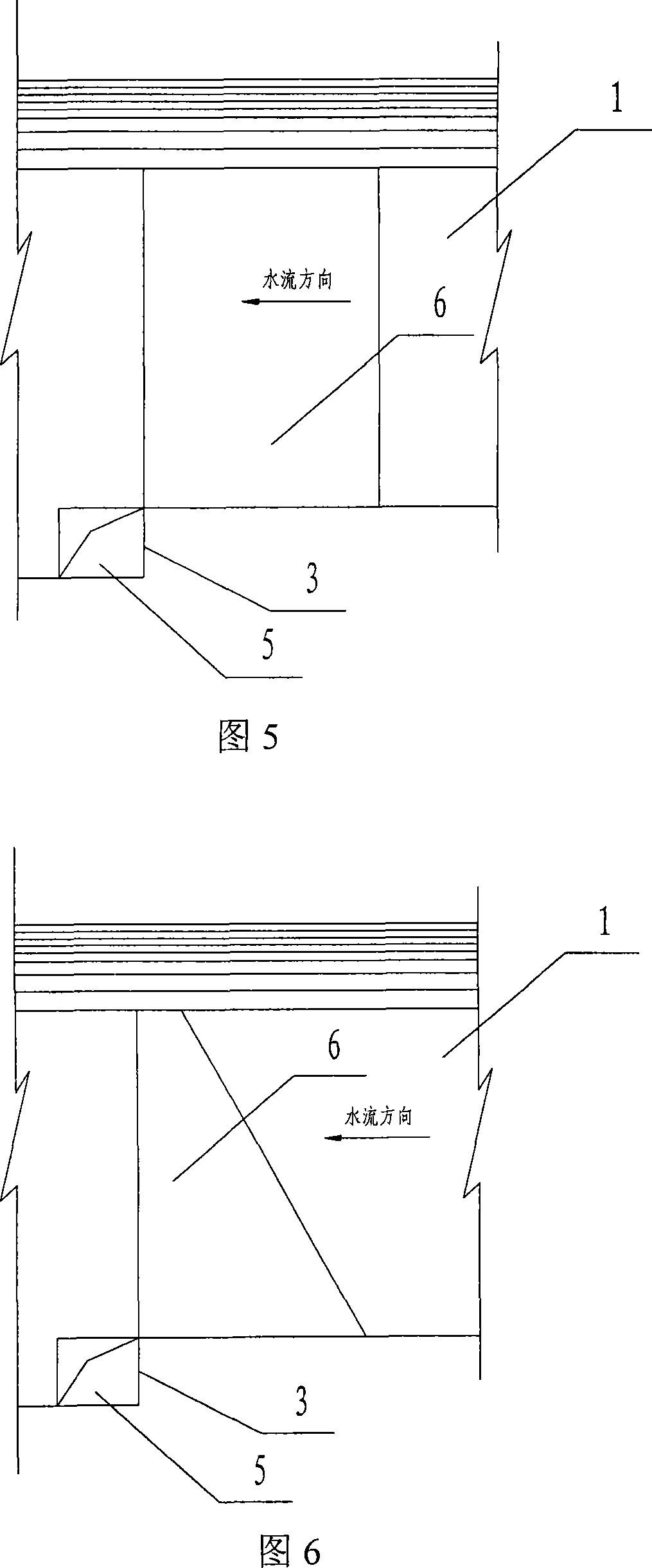

[0017] As shown in Figure 3, the flood discharge tunnel with a full-section aerated structure provided in this embodiment is provided with an aerated drop sill 3 at the bottom of the flood discharge tunnel 1, and an aerated drop sill 3 is provided outside the walls 2 on both sides of the same section of the same section. A relative "L"-shaped ventilation shaft 4, the ventilation shaft 4 communicates with the ventilation hole 5 opened on the side walls 2 on both sides of the front and bottom of the aeration drop sill 3, so that air enters the space below the front and bottom of the drop sill to form a bottom cavity for aeration. A wedge-shaped deflector 6 is respectively added on the side walls 2 on both sides of the upstream of the aerated sill 3. Thickening is formed, and its upper and lower equal widths make it form a rectangle, as shown in Figure 5, and the deflector 6 also gradually thickens from the top of the hole to the bottom of the hole to form a wedge, as shown in Fig...

Embodiment 2

[0020] As shown in Figure 3, the flood discharge tunnel with a full-section aerated structure provided in this embodiment is provided with an aerated drop sill 3 at the bottom of the flood discharge tunnel 1, and an aerated drop sill 3 is provided outside the walls 2 on both sides of the same section. A relative "L"-shaped ventilation shaft 4, the ventilation shaft 4 communicates with the ventilation hole 5 opened on the side walls 2 on both sides of the front and bottom of the aeration drop sill 3, so that air enters the space below the front and bottom of the drop sill to form a bottom cavity for aeration. A wedge-shaped deflector 6 is respectively added on the side walls 2 on both sides of the upstream of the aerated sill 3. It is formed by thickening, and the length of the upper side near the roof of the cave is smaller than the length of the bottom side. From the top side, its lower part gradually extends and widens toward the upper and lower reaches of the aeration drop s...

Embodiment 3

[0023] As shown in Figure 3, the flood discharge tunnel with a full-section aerated structure provided in this embodiment is provided with an aerated drop sill 3 at the bottom of the flood discharge tunnel 1, and an aerated drop sill 3 is provided outside the walls 2 on both sides of the same section. A relative "L"-shaped ventilation shaft 4, the ventilation shaft 4 communicates with the ventilation holes 5 opened on the side walls at the front and bottom of the aeration sill 3, so that air enters the space below the front and bottom of the sill to form the bottom cavity for aeration. A wedge-shaped deflector 6 is respectively added on the side walls 2 on both sides of the upstream of the aerated sill 3. It is formed by thickening, and the length of the upper side near the roof of the cave is zero, and its lower part gradually extends and widens toward the upper and lower reaches of the aerated sill 3 to form a triangle, as shown in Figure 7, and the deflector 6 also extends f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com