Magnetizer drilling jig gripper for electro-hydraulic servo valve

A technology of electro-hydraulic servo valve and magnetizer, which is applied in the direction of drilling jigs for workpieces, etc., can solve problems such as inaccurate positioning, and achieve the effects of improving processing efficiency, convenient processing, and convenient positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

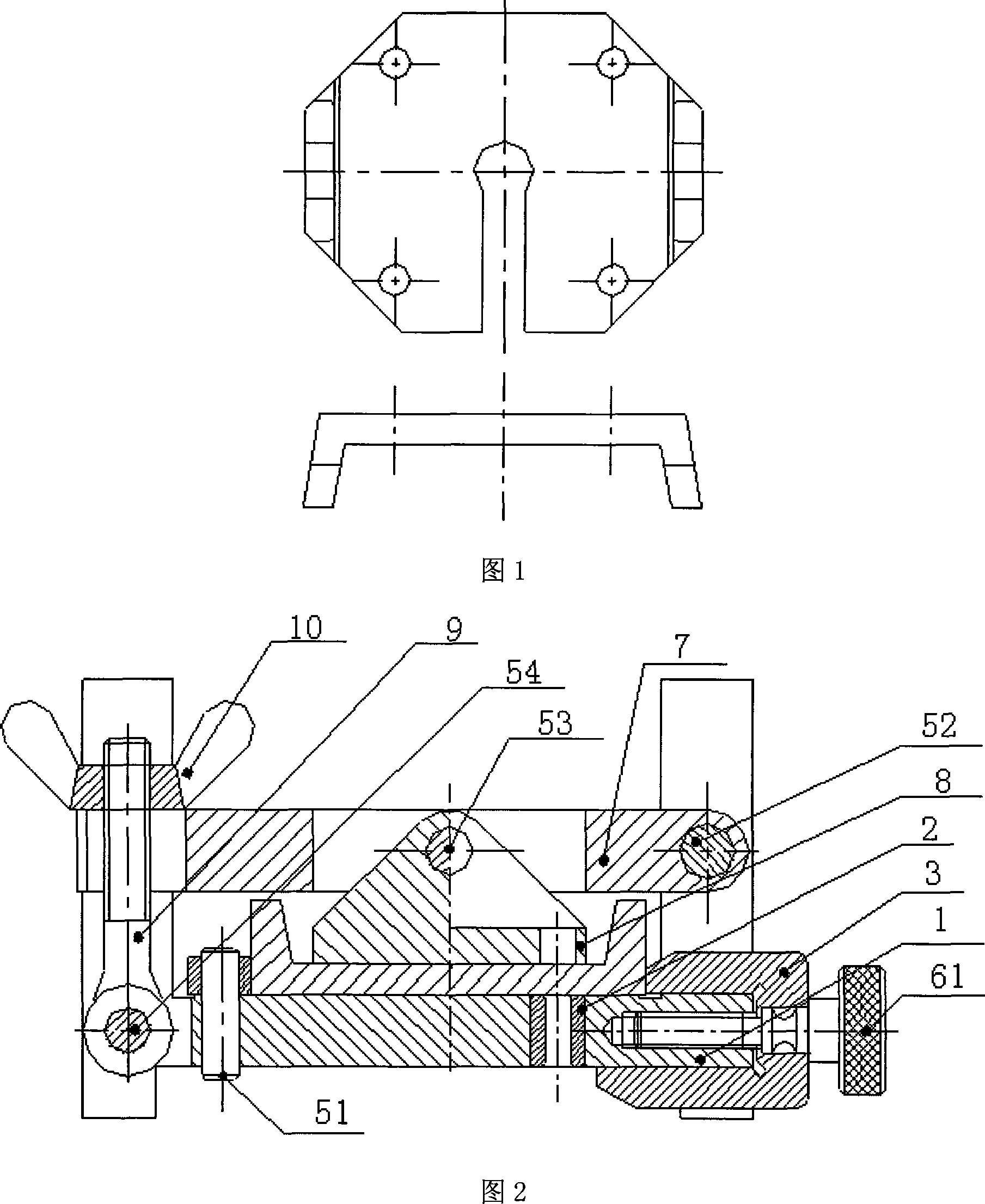

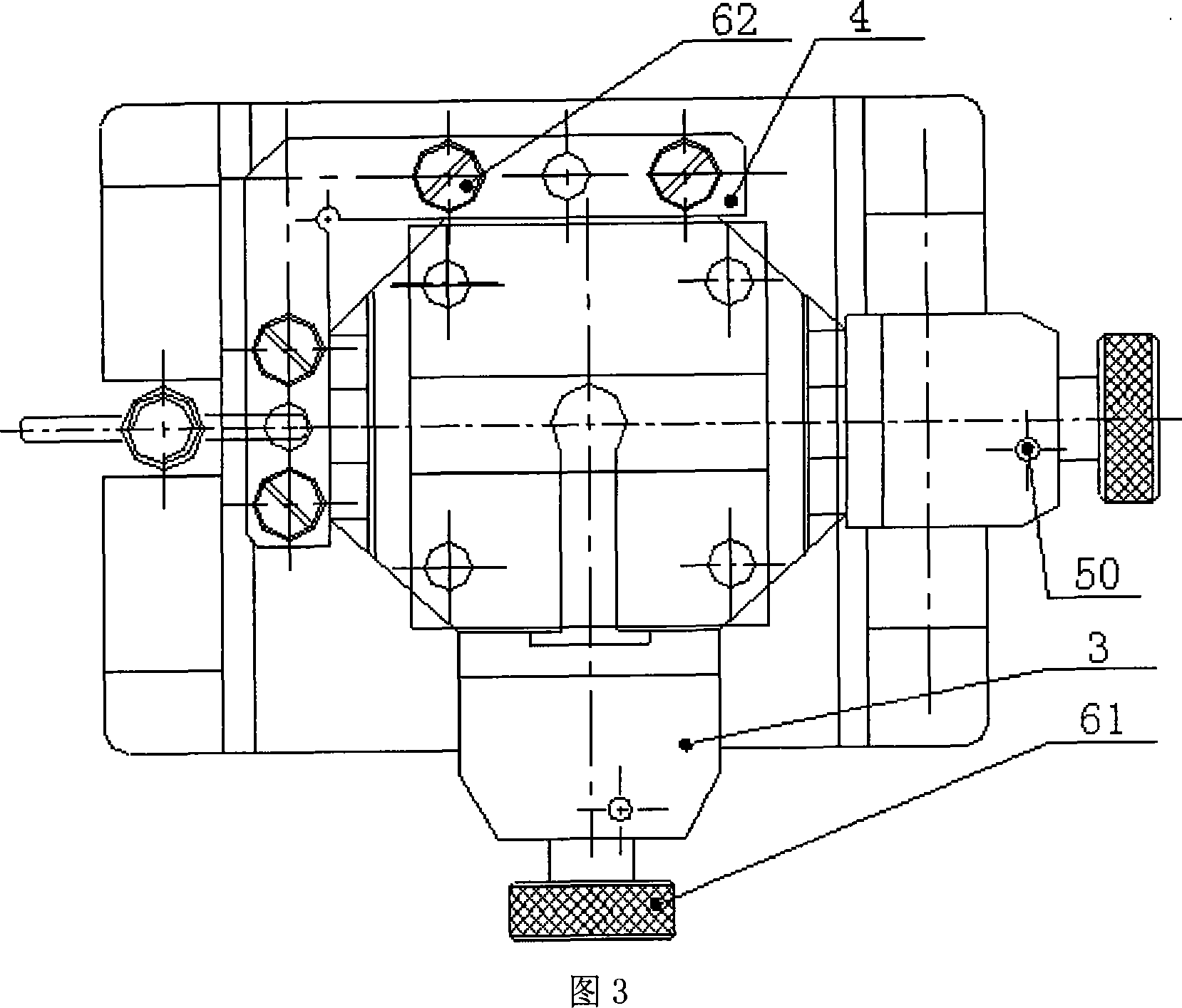

[0016] As shown in Figures 1, 2, and 3, an electro-hydraulic servo valve magnet guide jig fixture includes a jig body 1, a drill sleeve 2, a positioning plate 4, a cylindrical pin 51, two sliding positioning plates 3, screws 61, Elastic straight pin 50, support plate 8, screw 62, straight pin 52, rotary plate 7, straight pin 53, straight pin 54, joint bolt 9, butterfly nut 10. in:

[0017] Drilling template body 1 is an "H" type structure, which is convenient for clamping. There is a position in the middle to cooperate with drill bushing 2 and positioning plate 4, and a position for cooperating with screw 61, sliding positioning plate 3 and rotary plate 7 is provided on one side. "U"-shaped structure, the other side is provided with "U"-shaped structure that cooperates with swing bolt 9, and the front is provided with the position that cooperates with screw 61, sliding positioning plate 3, has formed a by positioning plate 4, screw 61 The positioning structure that cooperates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com