Fracture paratope machine

A technology of alignment machine and lead screw, which is applied in the field of medical devices, can solve the problems of prolonging healing time, prolonging bone regeneration time, increasing patient pain and economic burden, and achieving the goals of shortening healing time, reducing patient pain, and saving medical expenses Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

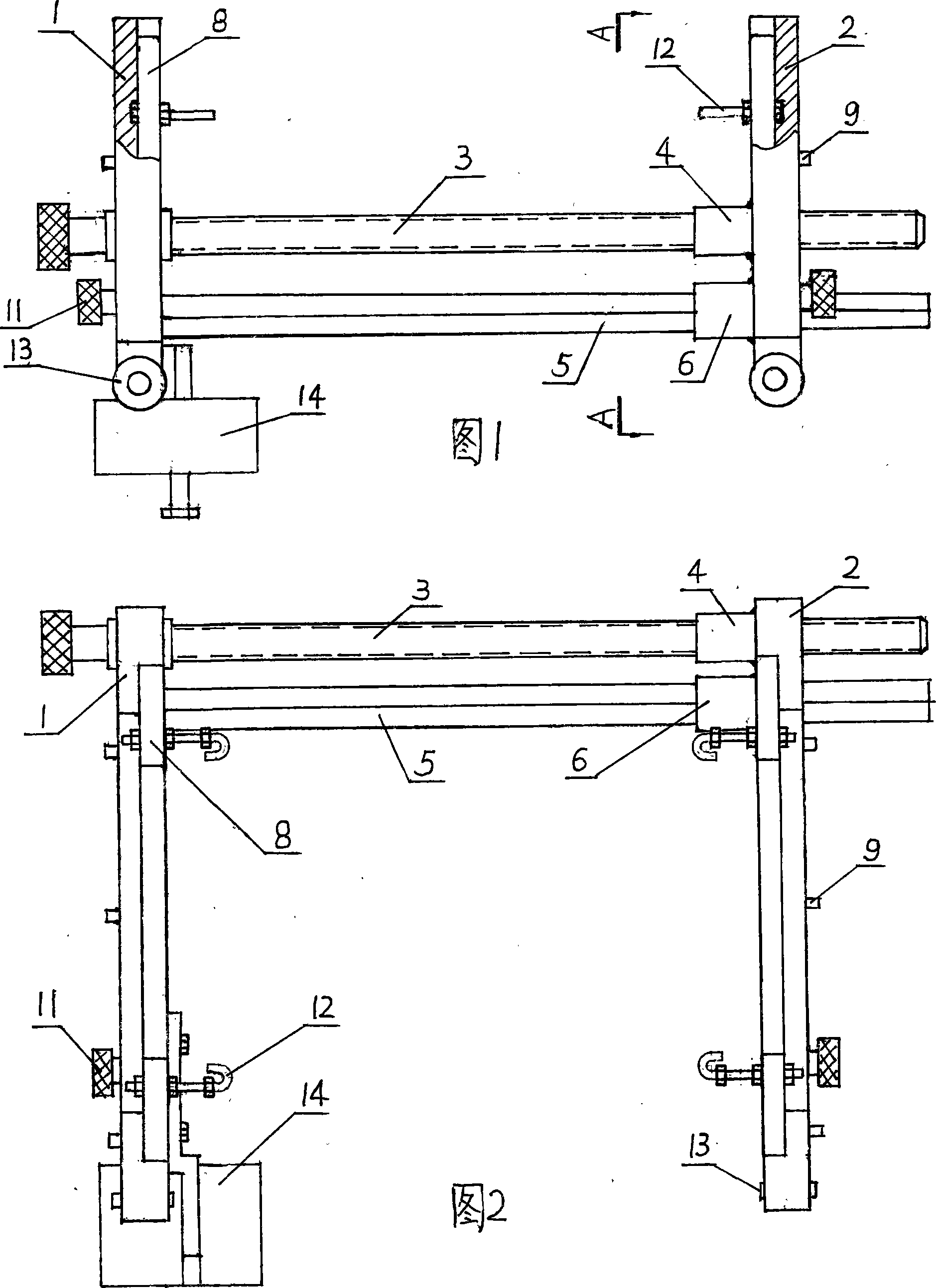

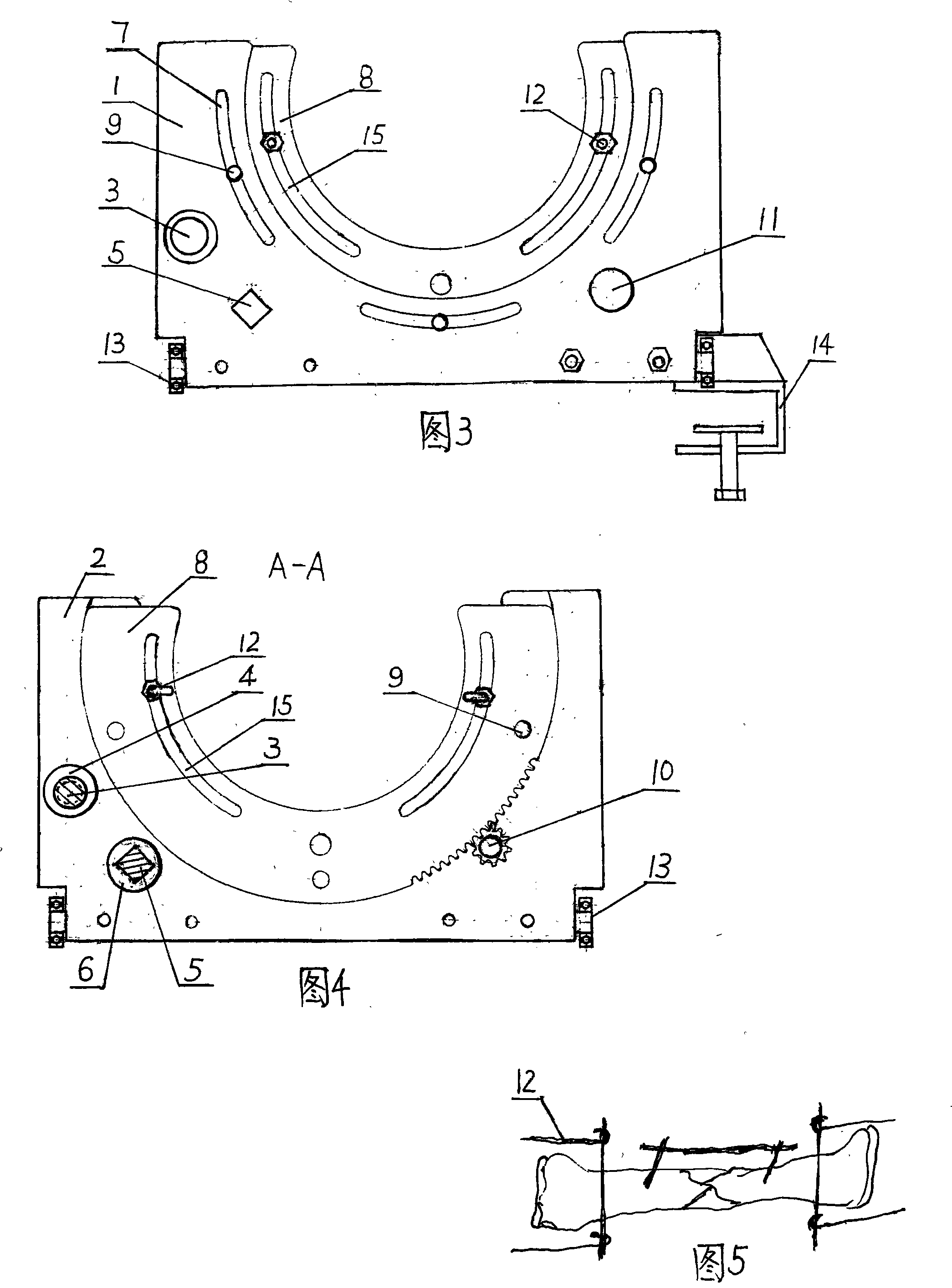

[0021] As shown in the figure, the neck of the lead screw 3 is inserted into the shaft hole of the main support plate 1, the lead screw nut 4 is fixedly connected with the auxiliary support plate 2, one end of the guide rod is fixed on the main support plate 1, and the other end is inserted into the main support plate 1. In the guide sleeve 6, the guide sleeve 6 is fixedly connected with the auxiliary support plate 2; the inner side of the upper middle part of the main and auxiliary support plates 1 and 2 is a semi-circular step concave inward, and there is an arc guide bar hole 7 on the semi-circular step. A semi-annular angle adjustment disc 8 with partial serrations on the edge with the same diameter as the outer diameter of the step is embedded on the semi-annular step, so that the guide pin 9 that the angle adjustment disc fits on the semi-annular step is located in the arc-shaped guide bar hole 7, Its lower end is screwed on the angle adjustment disc 8; the adjustment gea...

Embodiment 2

[0023] It is basically the same as Example 1, except that the arc bar hole 15 of the angle adjustment disc 8 is equipped with a clamping device with bolts.

Embodiment 3

[0025] It is basically the same as Example 1 or Example 2, except that the fixed sleeve frame 14 is installed on the lower part of the sub-support plate 2 with bolts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com