Image sensor structure and manufacturing method thereof

A technology of an image sensor and a manufacturing method, which is applied in the manufacturing of semiconductor/solid-state devices, radiation control devices, electrical components, etc., can solve the problems of increased density of pixel area image sensors, deterioration of crosstalk phenomenon, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

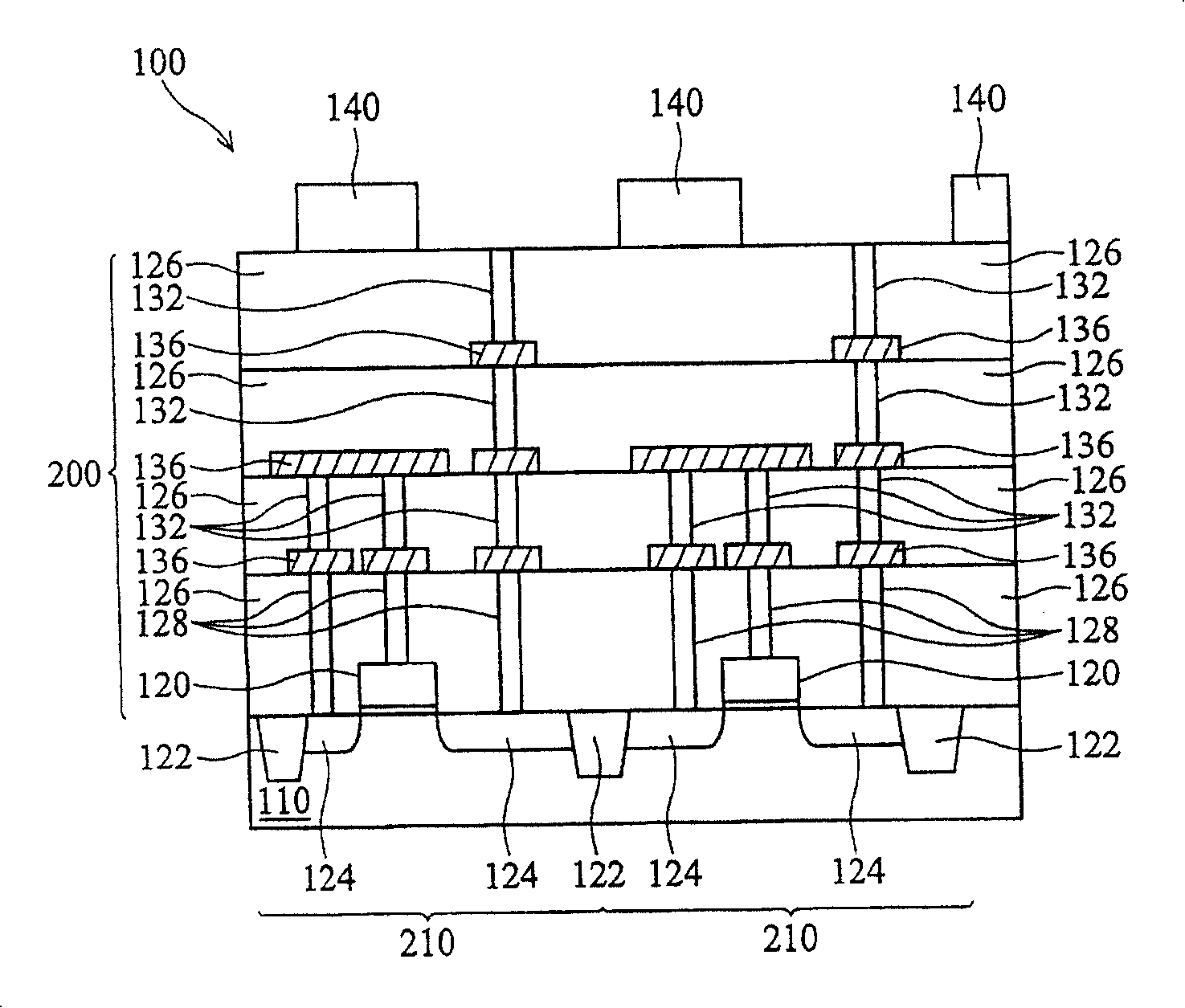

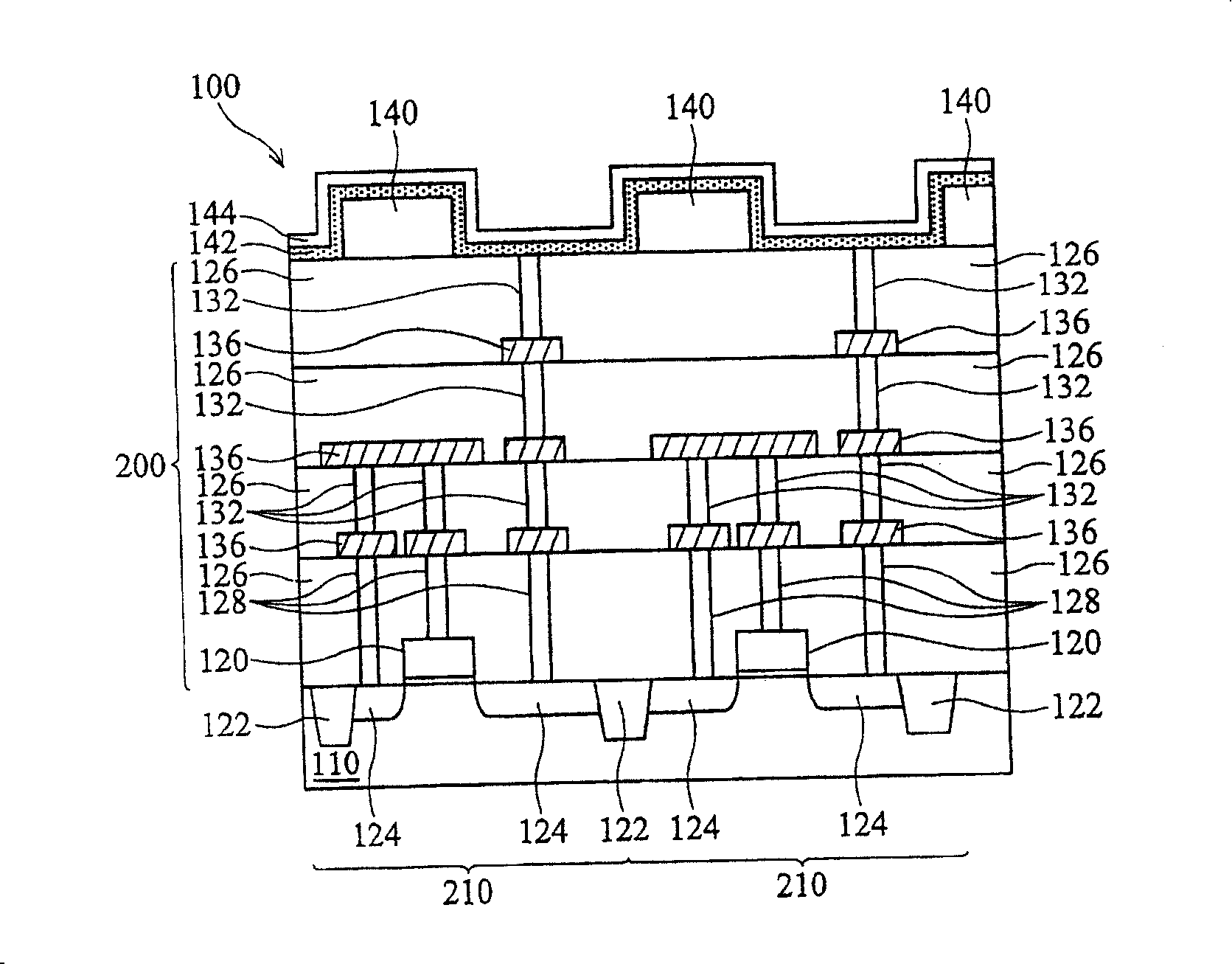

[0030] The image sensor of the preferred embodiment of the present invention and the method for forming it are described in more detail below using process cross-sectional diagrams. In each embodiment of the present invention, the same symbols represent the same components.

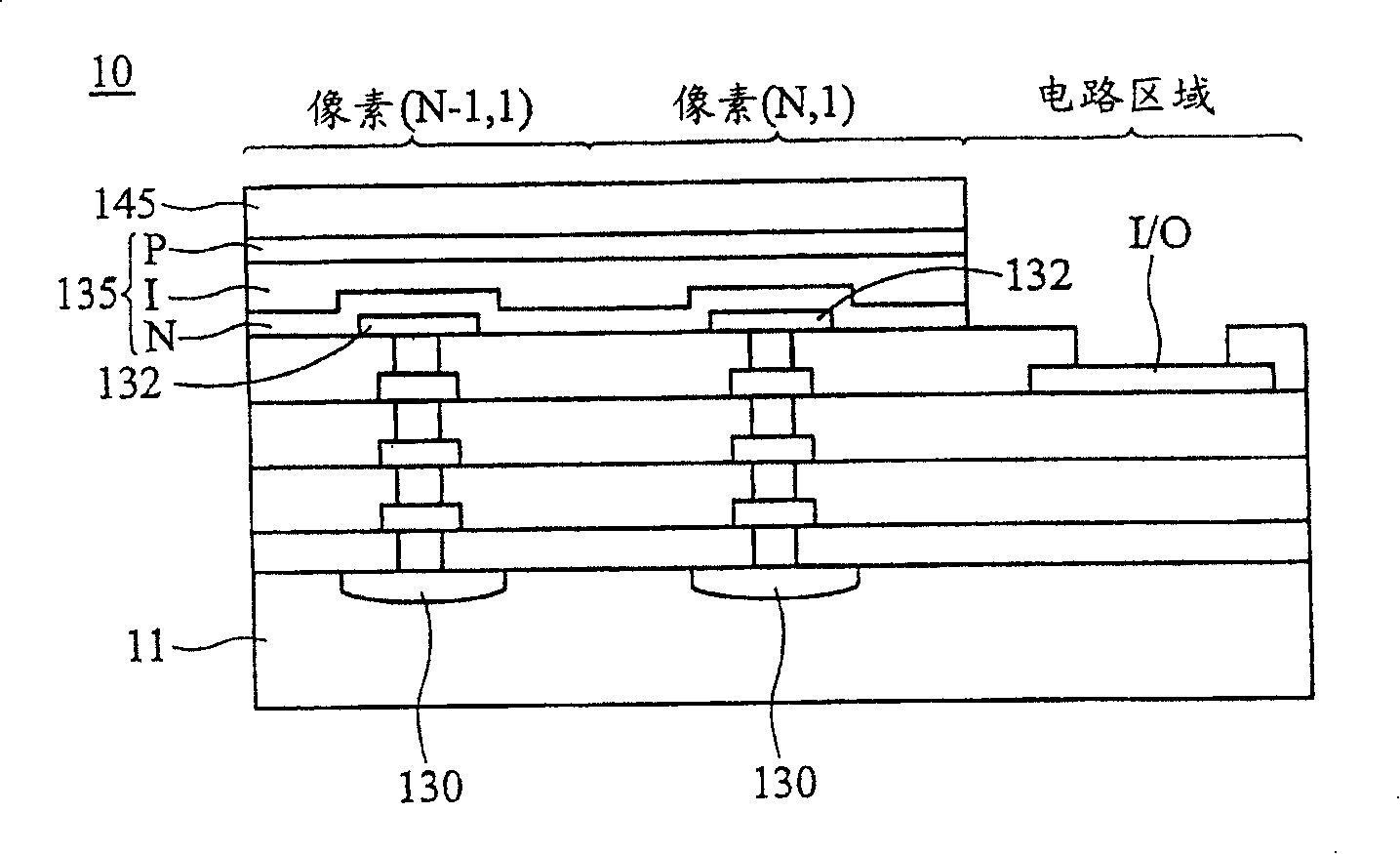

[0031] Please refer to Figures 2a to 2f , which shows a series of cross-sectional process diagrams of the image sensor structure 100 according to the preferred embodiment of the present invention. Please refer to FIG. 2a, the main components forming the image sensor structure 100 of the preferred embodiment of the present invention include a substrate 110, which includes a plurality of pixel regions 210, and the substrate 110 can be a silicon substrate, a silicon on insulator (silicon on insulator, SOI) substrate or other semiconductor material substrates. A plurality of shallow trench isolations (shallow trench isolation, STI) 122 are formed in the substrate 110 . One or more image sensor circuit stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com