X optical detection machine for project tire

A technology of engineering tires and testing machines, applied in the direction of material analysis using radiation, etc., can solve problems such as waste of manpower and material resources, difficult operation process, etc., achieve high degree of automation, improve factory pass rate, and accurate and reliable detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The engineering tire X-ray inspection machine provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

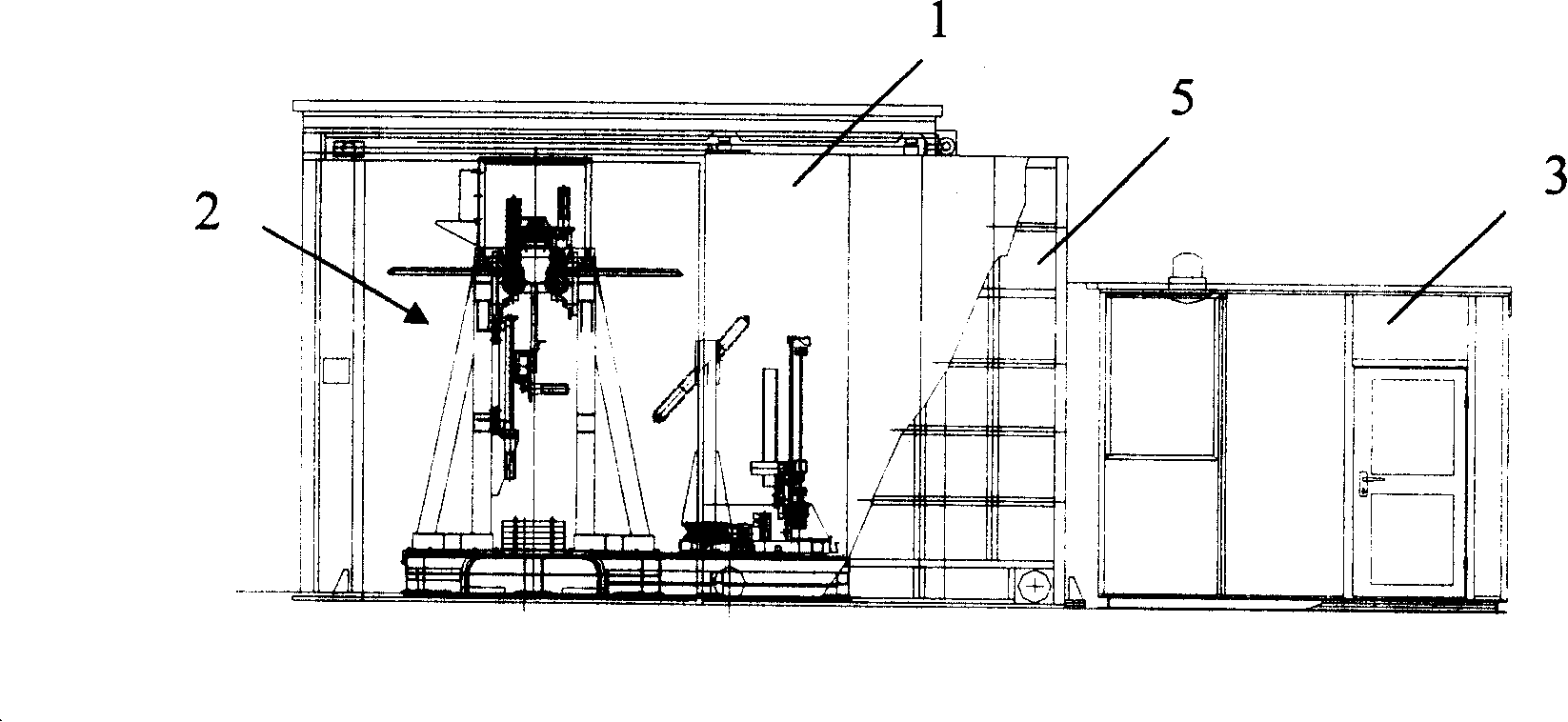

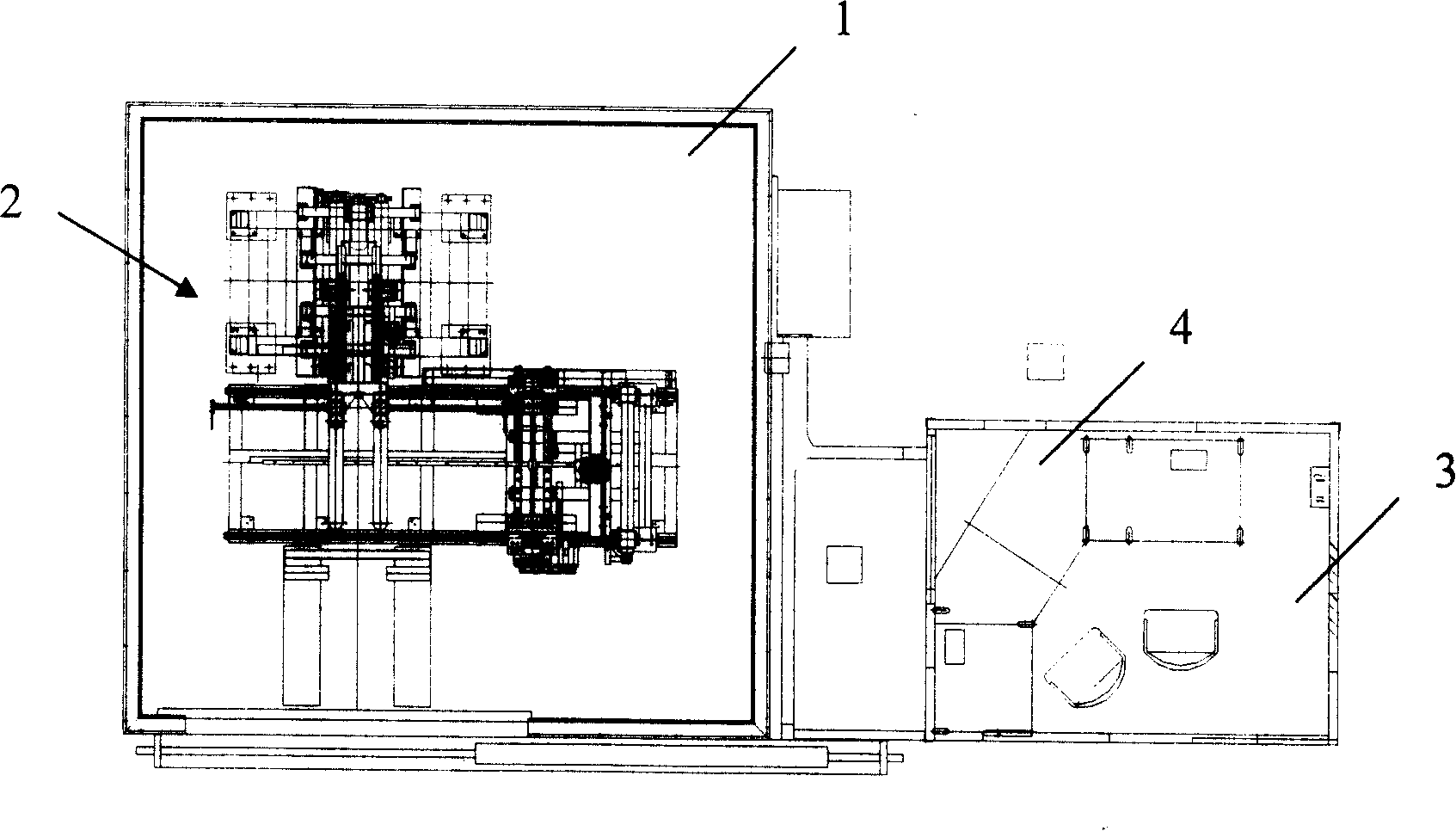

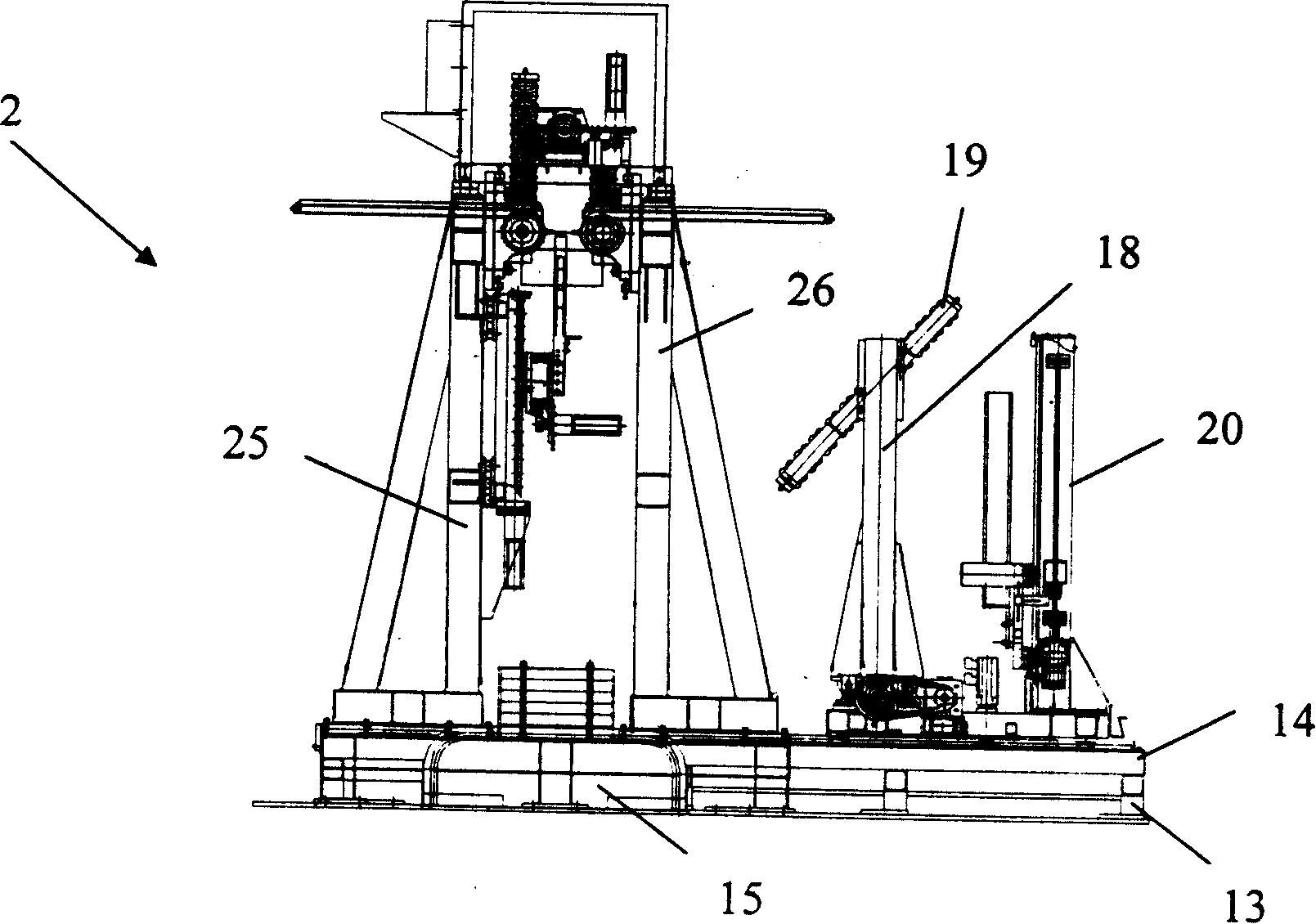

[0024] Such as Figure 1 to Figure 12 As shown, the engineering tire X-ray detection machine provided by the present invention comprises a lead room 1, a detection device 2, a control room 3 and an electrical control device 4; wherein an electric lead room door 5 is provided on one side of the lead room 1; the detection device 2 Set inside the lead room 1, including trolley group 6, centering device 7, U-shaped frame group 8, main frame group 9, opposite side group 10, drive group 11 and ball head group 12; control room 3 is set in the lead room 1 on the outside side; and the electrical control device 4 is set inside the control room 3 .

[0025] Such as Figure 6 As shown, the trolley group 6 mainly includes a frame 13 installed on the ground at the front part of the lead room 1, tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com