Cement concrete surface renovating material

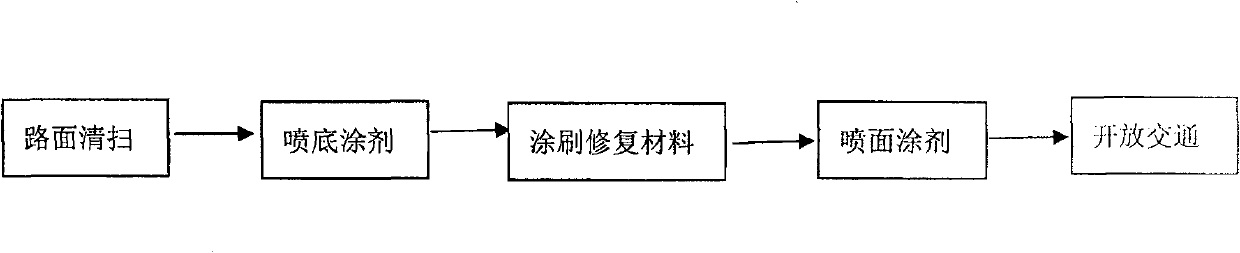

A cement concrete and surface repair technology, which is applied in the field of thin-layer repair materials on the surface of cement concrete pavement, can solve the problems of large damage, reduced pavement performance and service life, and detachment of cement slurry on the pavement surface, and achieves the effect of simplifying the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

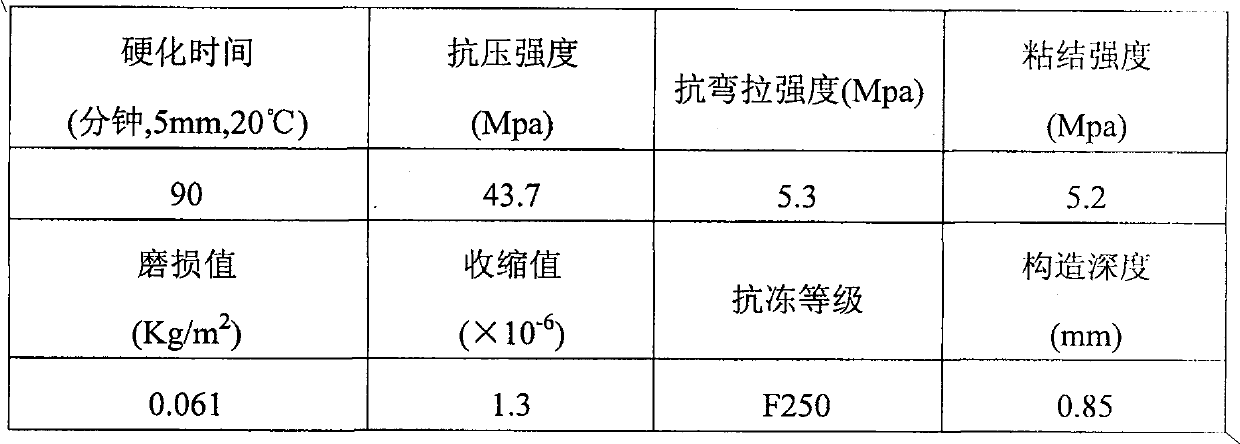

[0034] The formula of the cement concrete surface repair material is composed of resin, Portland cement, quick-hardening sulfoaluminate cement, dry river sand without soil, 40-70 mesh quartz sand, lime calcium powder and expansion agent. The weight of each component is The parts are: resin 80, Portland cement 280, fast hardening sulfoaluminum cement 32, dry river sand without soil 320, 40-70 mesh quartz sand 260, ash calcium powder 8, conventional high-efficiency water reducer 1.8, conventional Bulking agents 18.2.

[0035] In actual use, it is divided into component A of repair material and component B of repair material, and used in conjunction with component A of repair material, including Portland cement, rapid hardening sulfoaluminate cement, quartz sand, and composite admixture, and its weight percentage range: 20-30% of Portland cement, 20-30% of quick-hardening sulfoaluminate cement, 50-70% of quartz sand, and the rest are composite admixtures, accounting for about 2-4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com