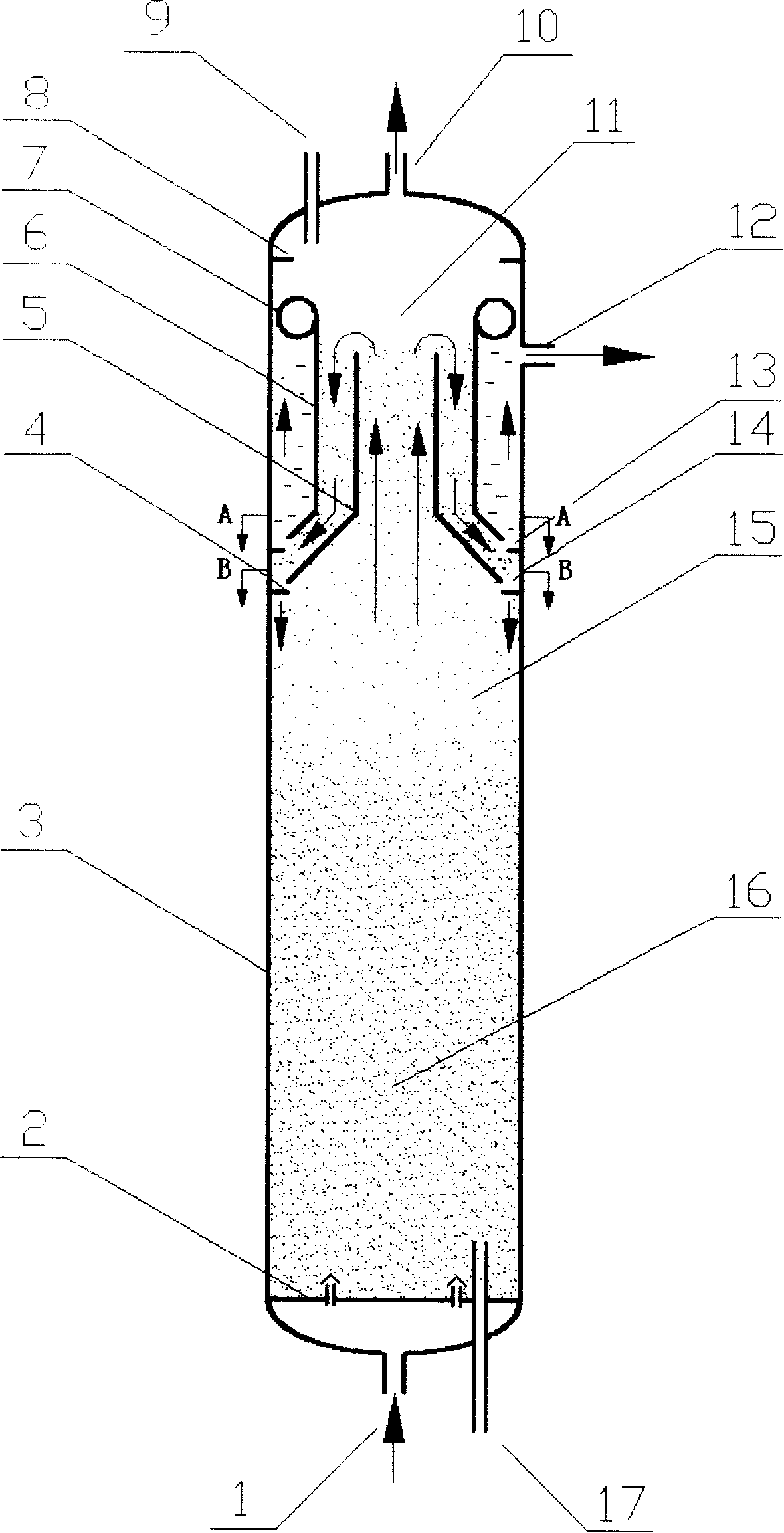

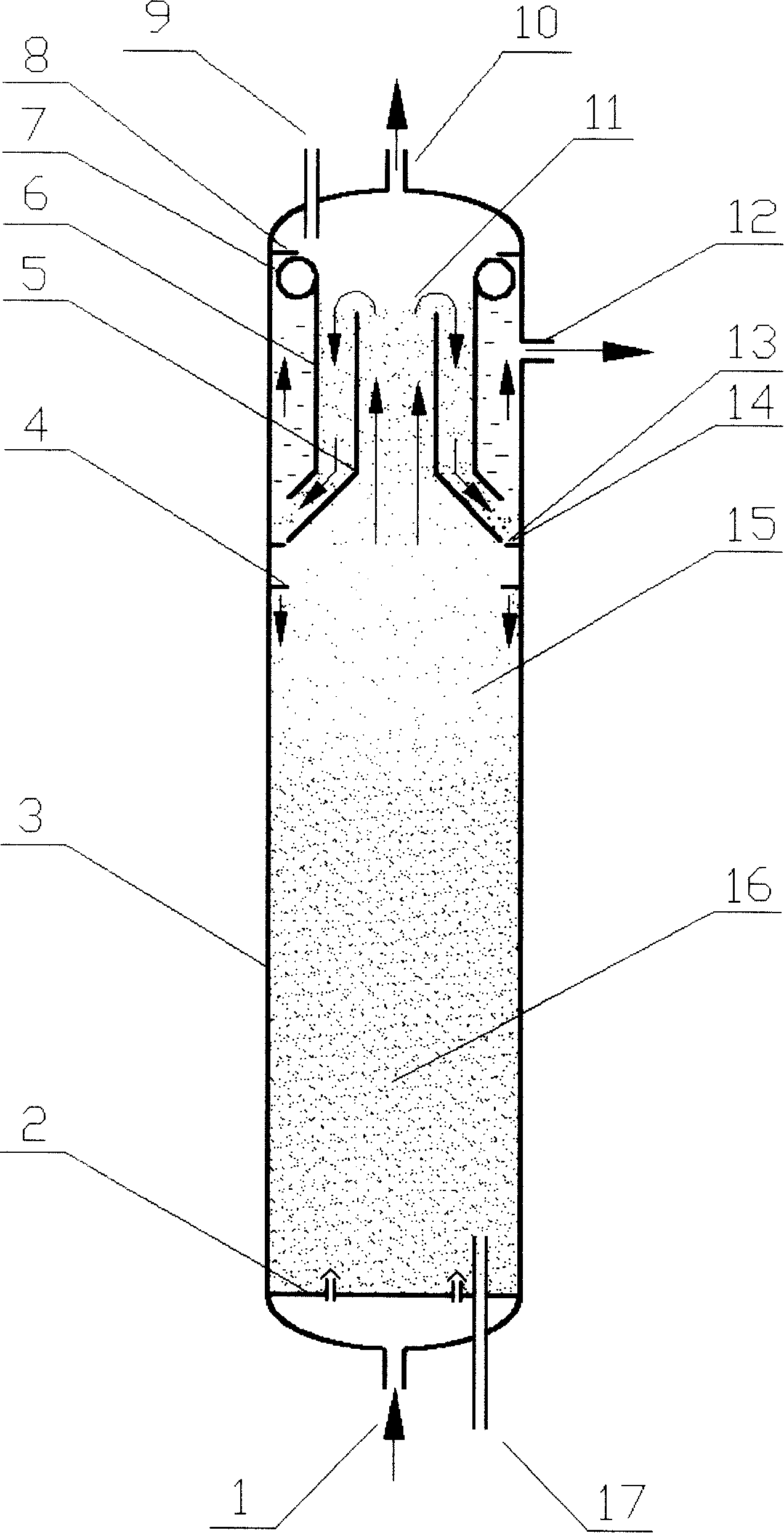

Three-phase fluidized bed reactor

A fluidized bed reactor and reactor shell technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problems of inability to guarantee operation, reduce product quality, catalyst loss, etc., and achieve long-term stable operation. Avoid a large number of carry out and ensure the effect of efficient separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

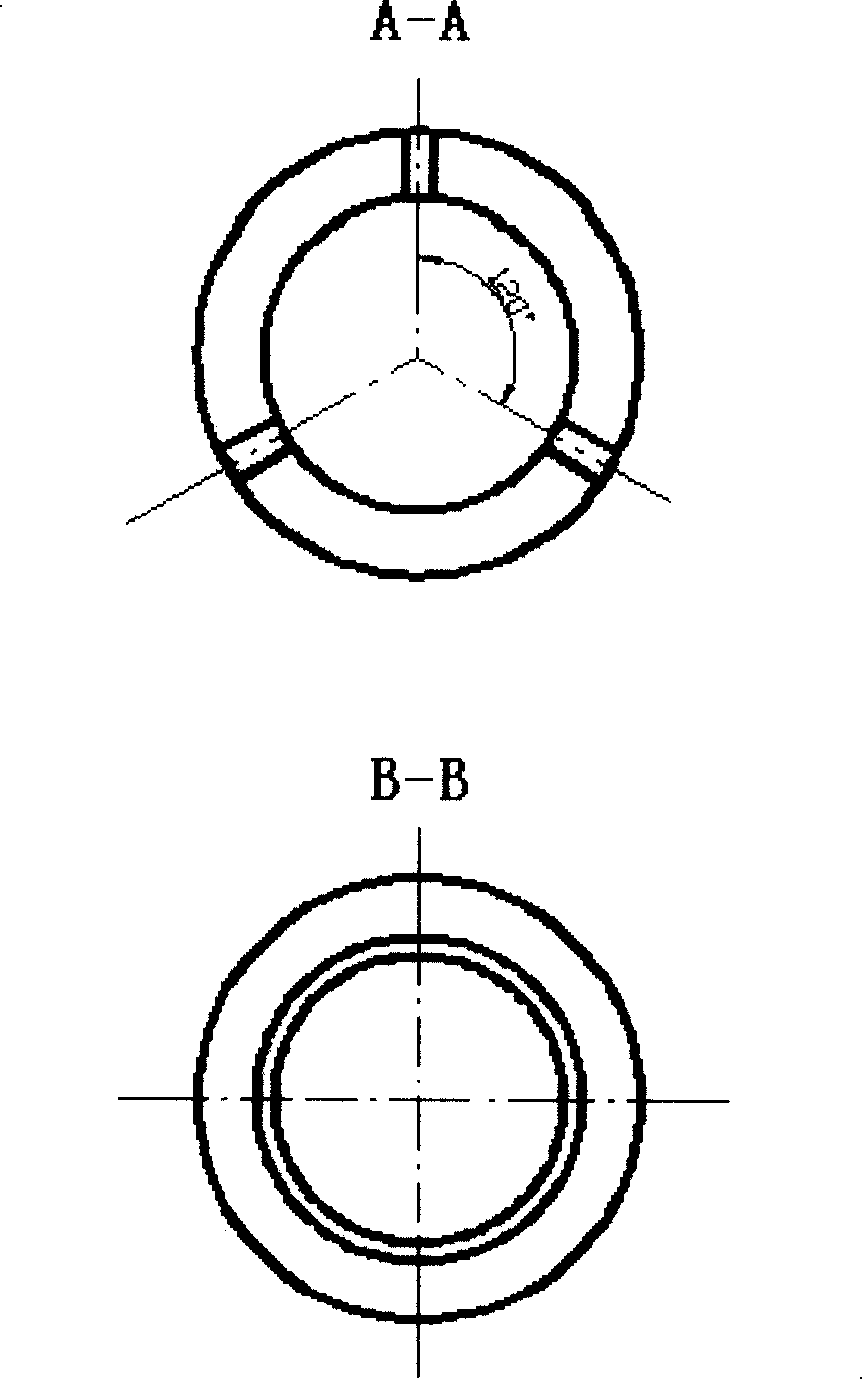

Embodiment -1

[0037] According to the selection of the three-phase separator size of the present invention, a three-phase separator fluidized bed medium-sized reactor cold mold test has been carried out, and the size of the medium-sized cold mold device is: the inner diameter of the reactor shell=160mm, the diameter of the reactor shell Height = 3000mm, shell effective volume 60L, separator height = 380mm, diameter of the cylindrical part of the central tube of the separator = 92mm, bottom diameter of the tapered opening at the lower part of the inner cylinder = 144mm, height of the lower cone part of the inner cylinder = 41mm, outer The diameter of the cylindrical part of the cylinder = 128mm, the diameter of the bottom of the opening of the conical part = 138mm, the height of the conical part = 64mm, the section of the buoy is circular, the diameter = 100mm, its lower edge is connected with the top of the outer cylinder of the separator, and the upper part of the buoy The height difference...

Embodiment -2

[0040] Based on the cold model test, a hydrodemetallization test of atmospheric residue oil in sand was carried out on a 60L medium-sized device. Wherein the size of the reactor is the same as in Example 1, and the test conditions and results are shown in Table 2.

Embodiment -3

[0042] Based on the cold model test, a hydrodemetallization test of atmospheric residue oil in sand was carried out on a 60L medium-sized device. Wherein the size of the reactor is the same as in Example 1. After 1200 hours, it was found that the amount of catalyst carry-over increased rapidly, so the three-phase separator discharge port was decoked, and the amount of catalyst carry-over returned to the normal range after decoking. The test conditions and results are shown in Table 3.

[0043] Table 1 The relationship between the oil intake, intake air volume and catalyst carryover volume of the 60L cold mold device

[0044]

[0045] Note: The intake volumes of 6 and 7 are changed in a short period of time, which is used to examine the strain capacity of the three-phase separator.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com