Gardening machinery or engineer machinery electric drive system

A technology of electric drive system and construction machinery, which is applied in the direction of mechanical equipment, machines/engines, etc., and can solve the problems of large noise, large space, easy wear efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0006] Below in conjunction with accompanying drawing, best embodiment of the present invention and working principle are described in detail:

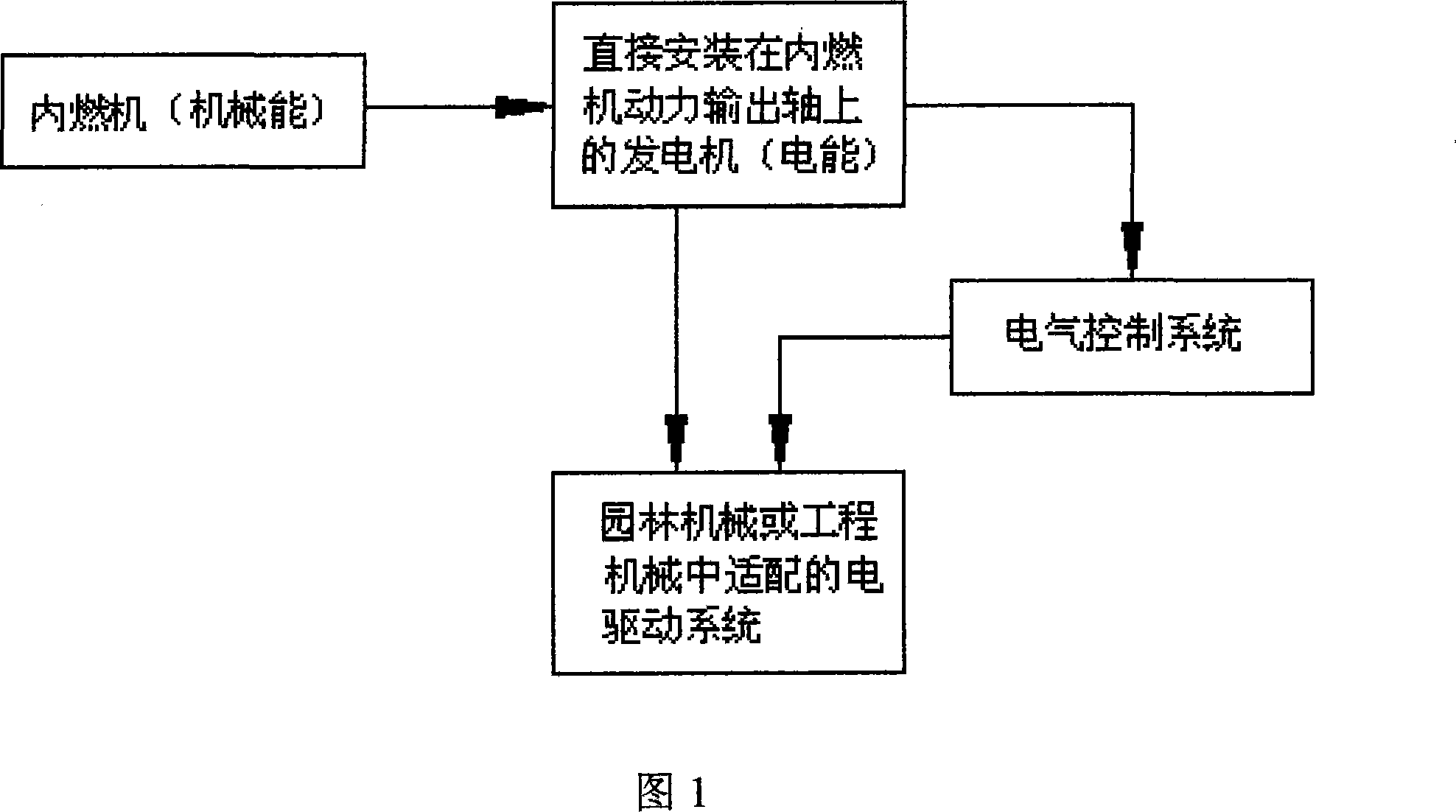

[0007] The invention utilizes the direct installation of the generator on the power output shaft of the internal combustion engine, and the compact installation structure saves space for the overall arrangement of garden machinery or engineering machinery; the power output of the internal combustion engine is divided into two paths, one part is output in the form of mechanical energy, and the other part is output in the form of mechanical energy. It is output in the form of electric energy and transmitted to the corresponding institutions in a corresponding and reasonable transmission mode; according to the functions of the whole machine and the needs of each institution, the spatial position and transmission path of the mechanical output and electric output of the system are reasonably arranged to obtain an economical system. It also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com