Petroleum drilling well drilling tool spherical flexible joint

A flexible joint, oil drilling technology, applied in drilling equipment, drill pipes, drill pipes, etc., can solve the problems of uneven and stable wellbore track curvature, and achieve the effect of simple structure, uniform and stable curvature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

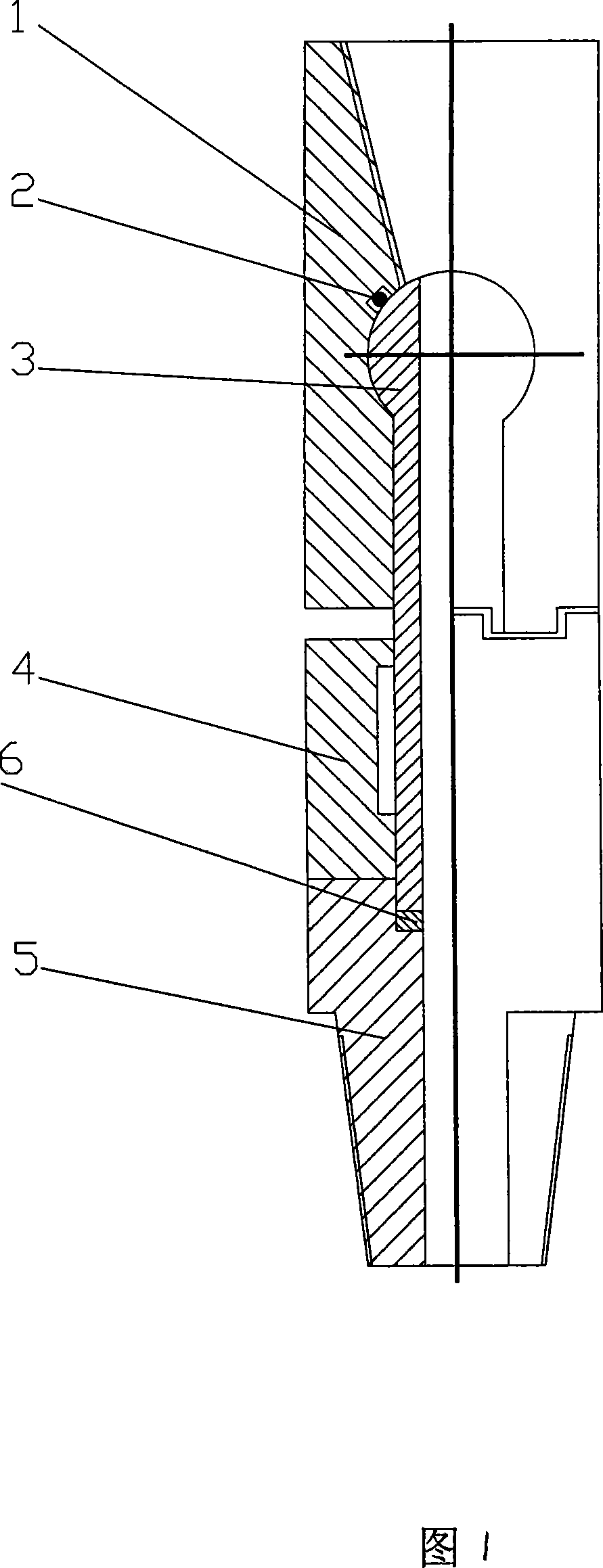

[0011] The present invention is mainly composed of a joint 1 with teeth, a seal 2, a spline shaft 3, a joint 4 with internal splines, a joint 5 with teeth and an adjusting piece 6, etc.

[0012] The present invention mainly adopts that a spherical head is provided at the front end of the spline shaft 3, which is sleeved on the joint 1 with teeth, and a seal 2 is arranged between them for sealing. The joint 4 of the spline is connected with the embedded joint 5 with teeth, and the adjusting plate 6 is installed on the bottom of the spline shaft 3 in the inner cavity of the embedded joint 5 with teeth.

[0013] Concave-convex platforms are arranged on the plane between the joint 1 with teeth and the joint 4 with internal splines to transmit torque, and the entire flexible joint is hollow and can transport drilling fluid.

[0014] The present invention i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com