Method for controlling thermal insulation layer construction by using step-type equal height thermal insulation batten

A technology of thermal insulation slats and construction methods, which is applied in the field of overhead floor slabs, shed surfaces, industrial and civil building walls, and can solve problems such as shear load of thermal insulation layers that are easy to crack, poor surface flatness accuracy, and environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

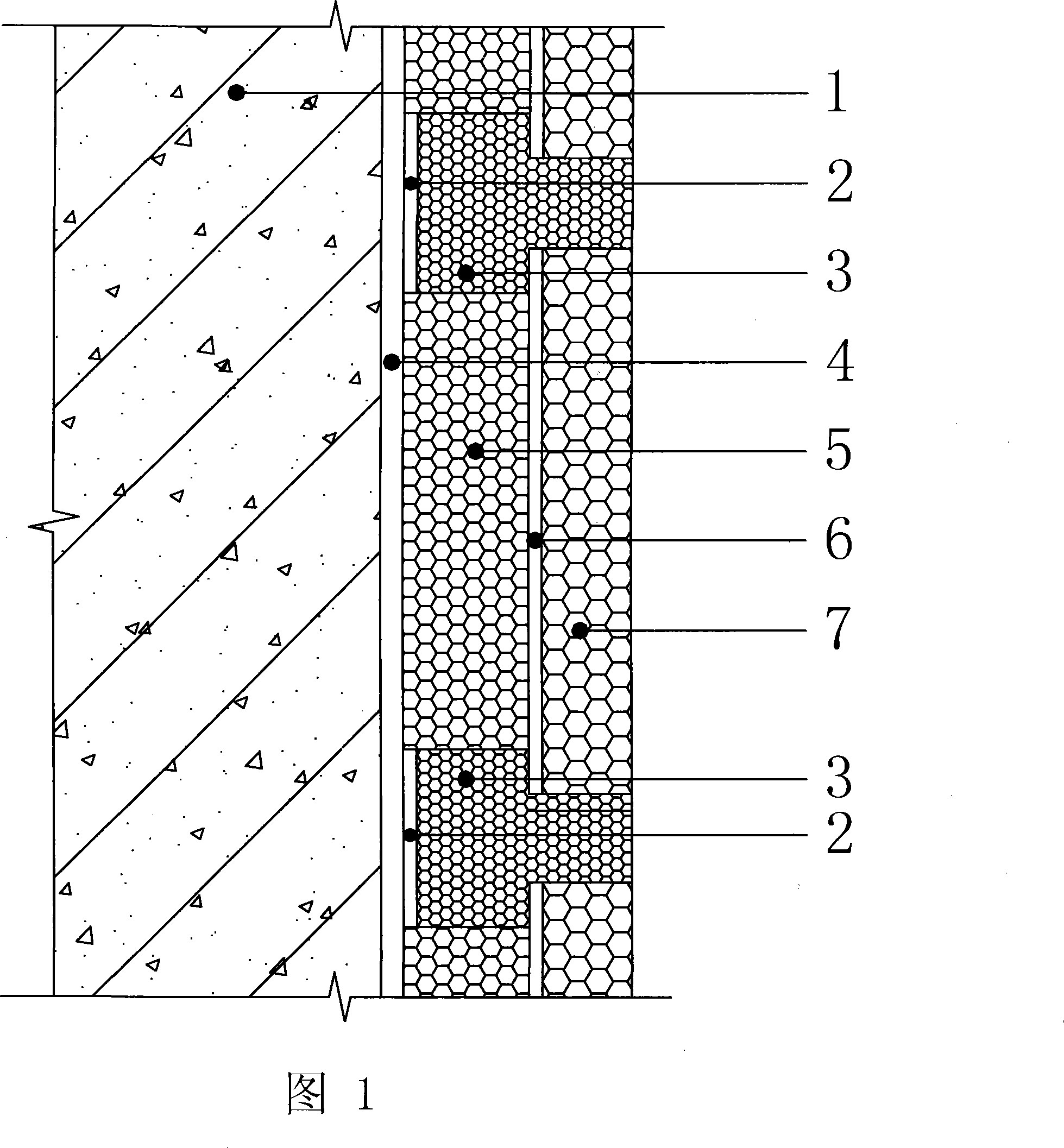

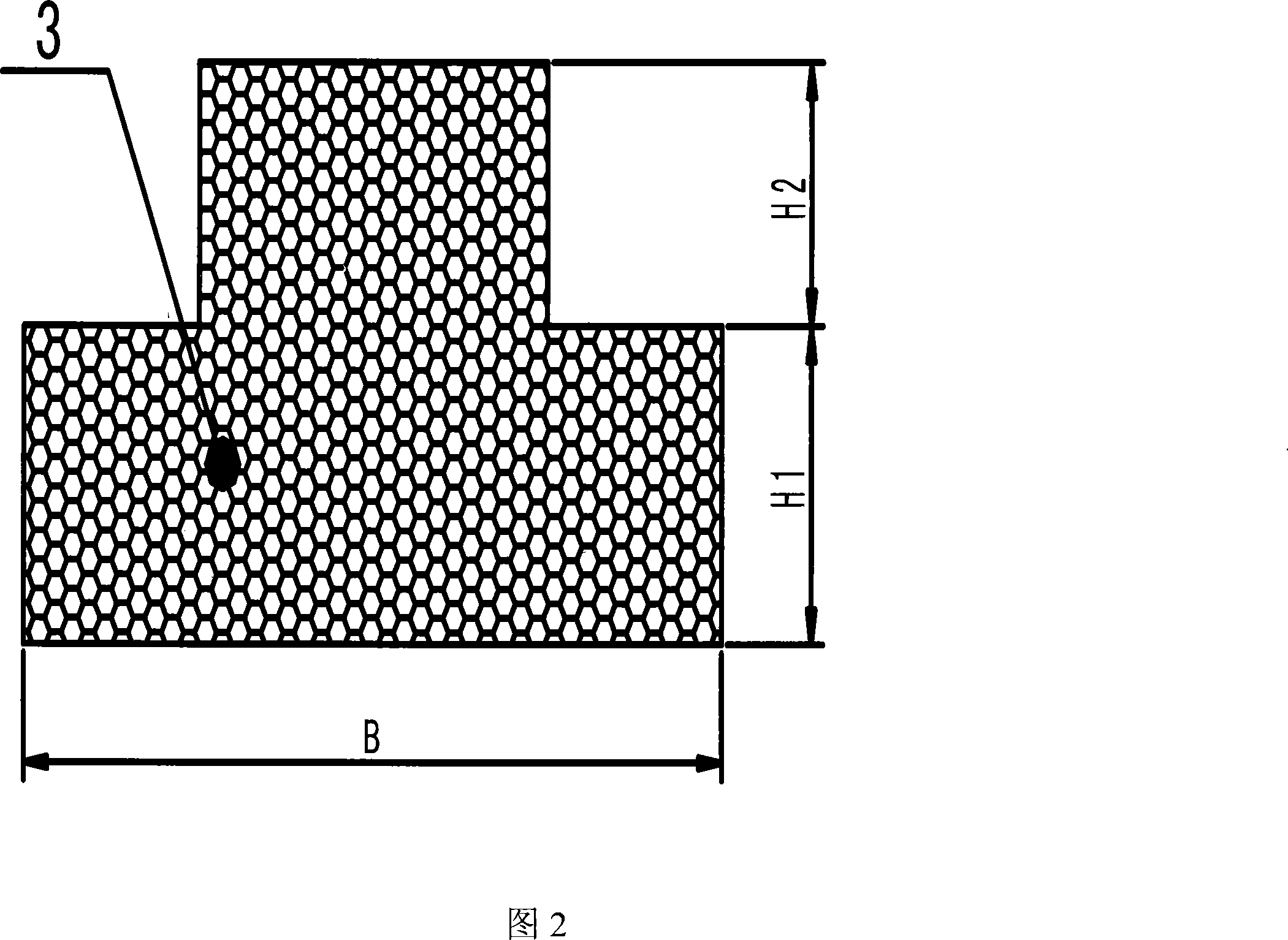

[0005] It includes an adhesive 2, a step-shaped contour-shaped insulation slat 3, a base layer interface agent 4, a rigid polyurethane foam insulation layer 5, an insulation layer interface agent 6, and a paste material insulation layer 7. Firstly, the step-type equal-height insulation slats 3 are horizontally connected to the base wall 1 by an adhesive 2 to form a benchmark control, and then polyurethane rigid foam insulation layers 5 and 5 are sprayed between the two step-type equal-height insulation slats 3 Smear the insulation layer 7 of slurry material to realize the effective control of layered thickness and total thickness of the insulation layer. According to the first step height H of the step-type equal-height insulation slat 3 1 Spray polyurethane rigid foam insulation layer 5, according to the second step height H of the step-type contour insulation slat 3 2 Smear the slurry material insulation layer 7. The width B of the step-type equal-height insulation slat 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com