Vehicle body assembling technique and vehicle body structure

An assembly process and body technology, which is applied in the field of automobiles, can solve the problems of RV compartment heat insulation, poor fire resistance, complex wooden skeleton structure, and time-consuming assembly, and achieve good shock resistance and energy absorption, convenient disassembly and transportation, The effect of saving wood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] A vehicle body assembly process method of the present invention is characterized in that it comprises the following steps:

[0026] a. Squeeze the whole board to prepare several molded caravan boards that constitute the vehicle body;

[0027] b. Seamless splicing, using aluminum profiles as the supporting frame to splice several molded caravan panels that constitute the body.

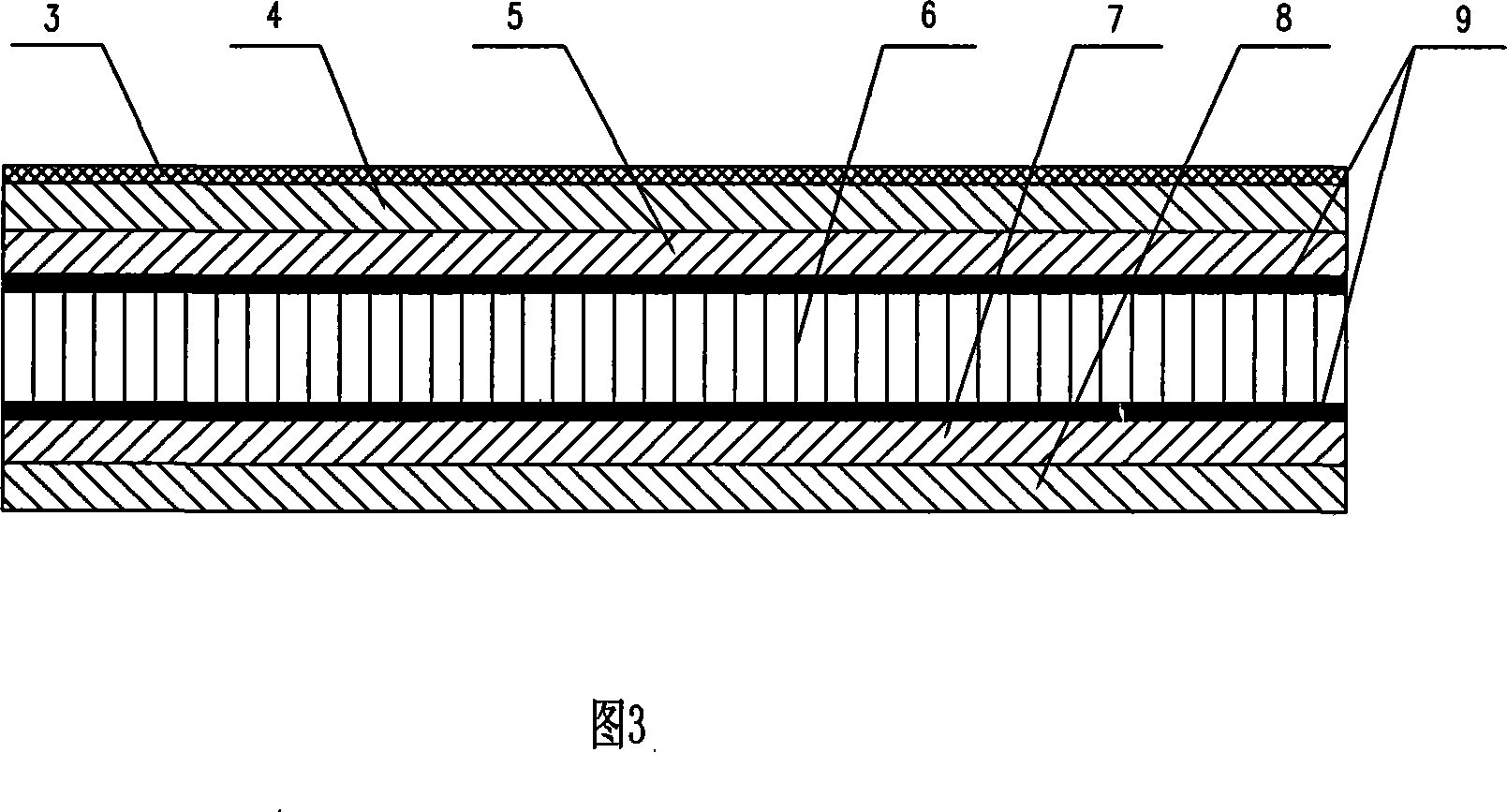

[0028] In the process of pressing the whole board, the facing material, the surface base material, the honeycomb core and the bottom base material are pressed into a honeycomb board, and wires and pipelines are pre-embedded in the honeycomb core before pressing. In addition to the countless small I-shaped ribs such as the honeycomb core, aluminum square profiles are also preset in the board to enhance the strength and rigidity, making the board surface flat without deformation, and enhancing the impact resistance.

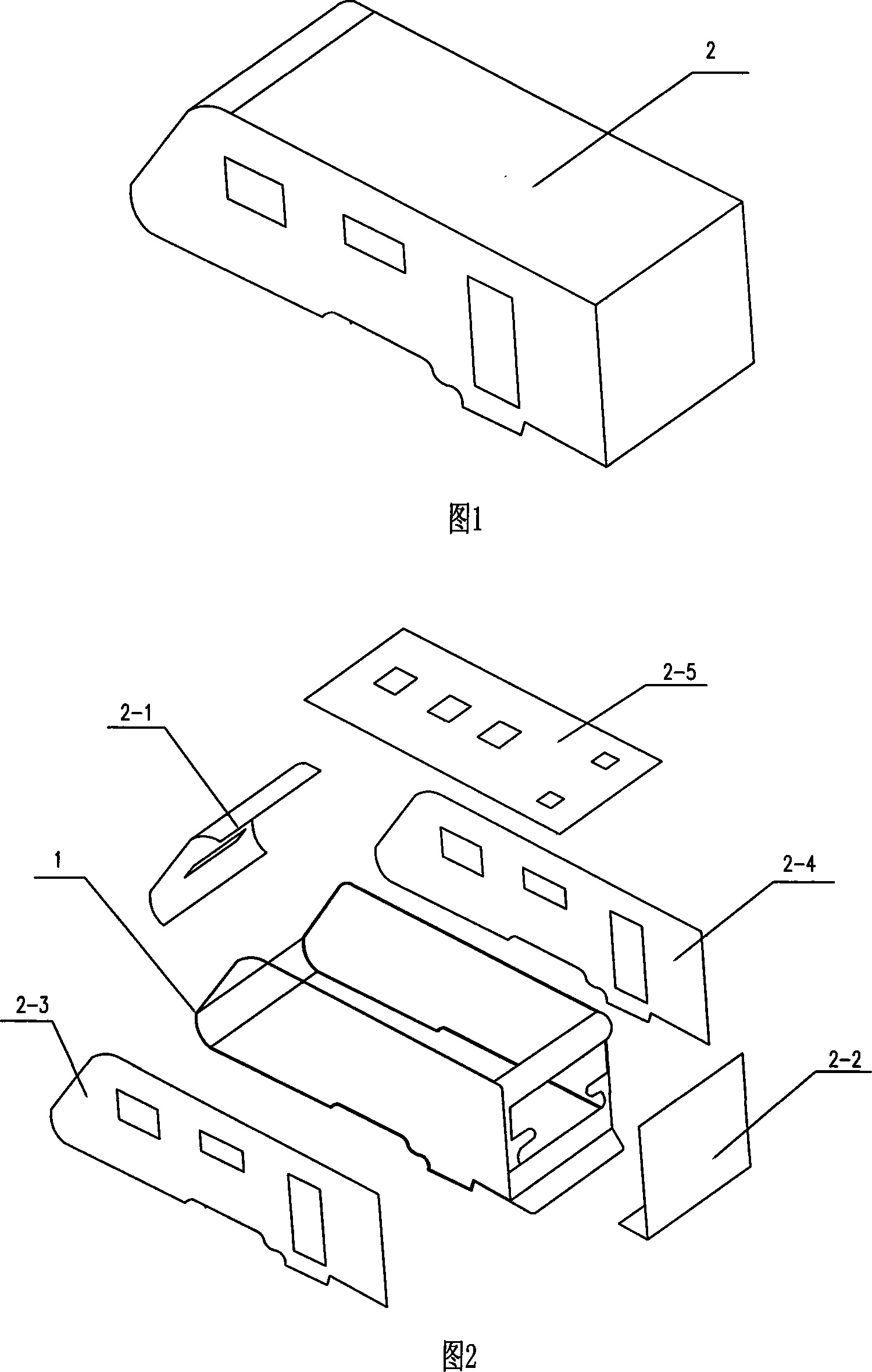

[0029] As shown in Fig. 1, Fig. 2 and Fig. 3, the vehicle body structure produce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com