One-way slip hydraulic base sealed packer

A slip seat and packer technology, which is applied in the field of isolation devices for sealing oil layers or tubing casings in oil and gas wells, can solve problems such as construction string elongation, easy-to-break rubber sleeves, and large piston effects, and achieve The effect of reducing accidents, convenient construction, good success rate and accuracy rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

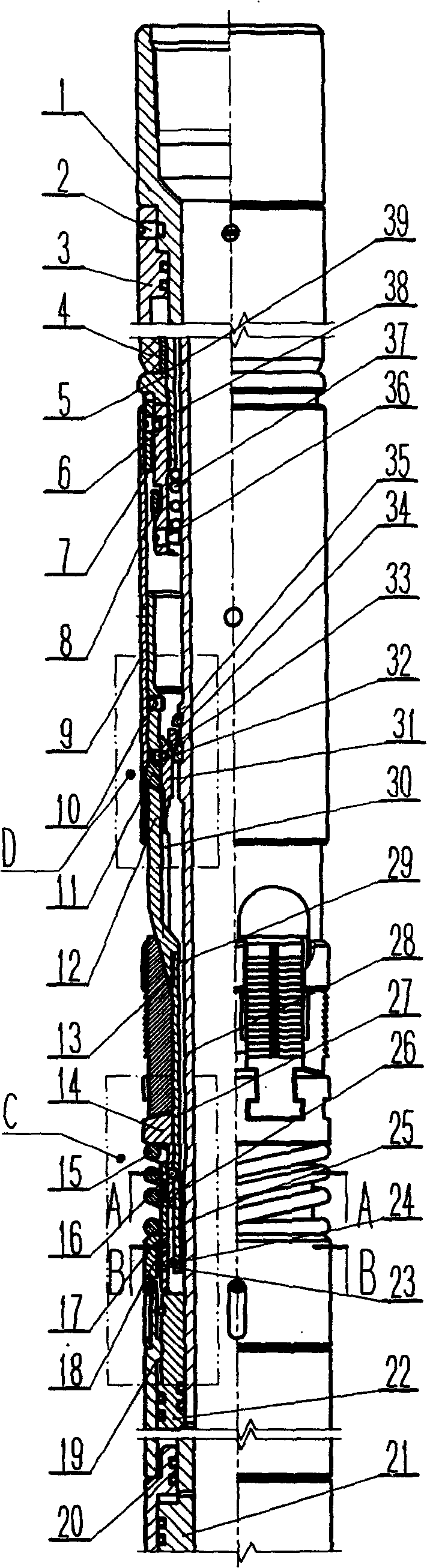

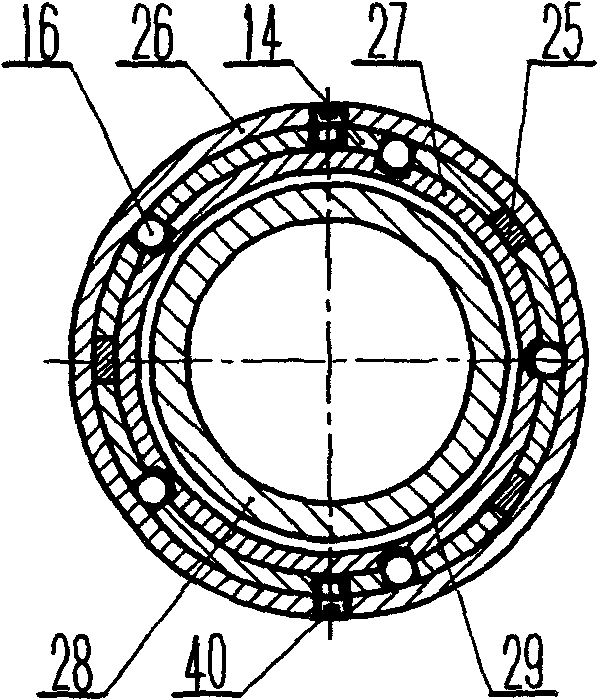

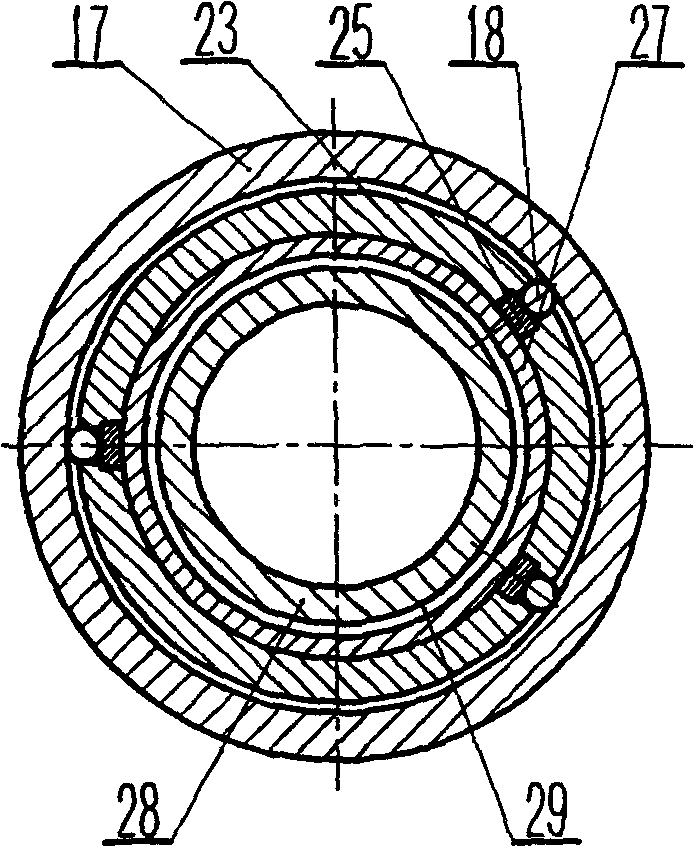

[0022] Such as Figure 1 to Figure 7 As shown, the present invention includes an upper joint 1, a lower joint 21, a central pipe 28, a rubber cartridge sealing mechanism, a slip mechanism and a seat sealing mechanism, and the seat sealing mechanism includes a seat sealing upper piston 22, a seat sealing lower piston 20, and a piston sleeve 19 , Cone connecting sleeve 28. The slip mechanism includes a one-way slip 13 , a slip seat 14 , a slip spring 15 , a spring seat 17 , an upper cone 12 and a push cylinder 23 . The well flushing piston sleeve 3 is connected to the upper joint 1 through the shear pin 2 . The lower end of the spring seat 17 is provided with a pin groove 51, and the piston sleeve 19 is slidably connected with the spring seat 17 through the pin 54 and the pin groove 51, so that the piston sleeve and the spring seat can slide relatively.

[0023] The spring seat 17 is slidably connected to the push cylinder 23 through a locking mechanism. The spring seat locki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com