Mn-Ag double active components desoxidant, preparation method and application thereof

A deoxidizer and double-active technology, applied in the field of olefin processing, to achieve high mechanical crushing strength, increase deoxidation capacity, and prolong the effect of regeneration cycle period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

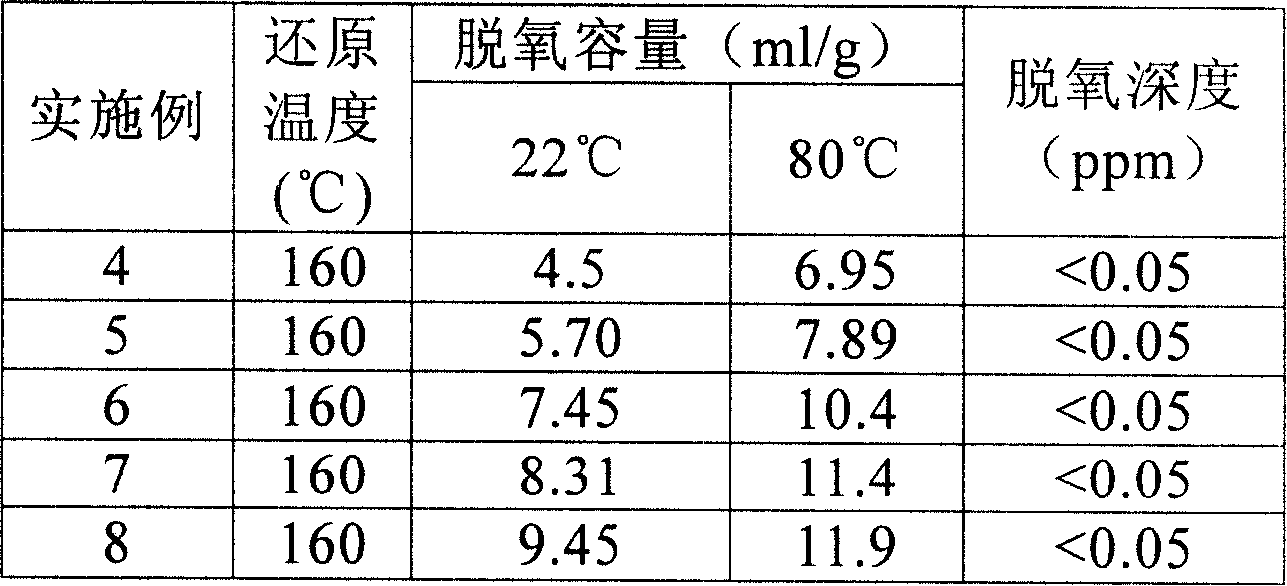

Examples

Embodiment 1

[0094] Example 1 Preparation of calcium aluminate and calcium aluminosilicate composite carrier

[0095] Weigh 5.50kg of high alumina bauxite with 74.2% by weight of alumina and 4.50kg of calcium carbonate with 53.3% by weight of CaO, pulverize to less than 70 μm, mix well, and calcinate at 1350-1450°C for 4 hours to discharge. , cooling, crushing, and 70μm sieving. The vector used in the present invention was prepared. Its weight percentage composition is: Al 2 o 3 53.9%, CaO 33.9%, SiO 2 5.84%, TiO 2 2.75%, Fe 2 o 3 2.0%, MgO 0.55%. Specific surface area 0.38 M 2 / g, the particle size is less than 70μm. XRD diffraction results show that the main component of the carrier is calcium aluminate CaAl 2 o 4 、CaAl 4 o 7 , and a small amount of calcium aluminosilicate Ca 2 Al 2 SiO 7 mixture.

Embodiment 2

[0096] The preparation of embodiment 2 calcium aluminate carrier

[0097] Weigh Al 2 o 3 6.90kg of industrial alumina with a content of 98.5% by weight and 5.40kg of heavy calcium carbonate with a content of 55.3% by weight of CaO, pulverized to less than 70μm, and fully mixed uniformly, calcined at 1550-1650°C for 5 hours, discharged, cooled, and pulverized , 70μm sieve. Prepare the calcium aluminate carrier used in the present invention. Its weight percentage composition is: Al 2 o 3 68.5%, CaO 30.2%, SiO 2 0.53%, Fe 2 o 3 0.5%. Specific surface area 0.48 M 2 / g, the particle size is less than 70μm. XRD diffraction results show that the main component of the carrier is calcium aluminate CaAl 2 o 4 and CaAl 4 o 7 .

Embodiment 3

[0099] Weigh MnCO with a particle size below 100 μm and a manganese weight percentage content of 44.1%. 3 25kg and 14kg of calcium aluminate and calcium aluminosilicate mixture below 70 μm prepared by the method of Example 1, the two are fully mixed. In the sugar coating machine, spray an appropriate amount of pure water to process it into a sphere with a diameter of 4mm to 5mm; place it for more than 24 hours and dry it in the air; dry it at 120°C for 8 hours to prepare a semi-finished product of deoxidizer without silver load.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com