Projection device

A projection device and projection lens technology, applied in projection devices, optics, instruments, etc., can solve problems such as not being suitable for mass production, affecting focusing distance, and component tolerances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

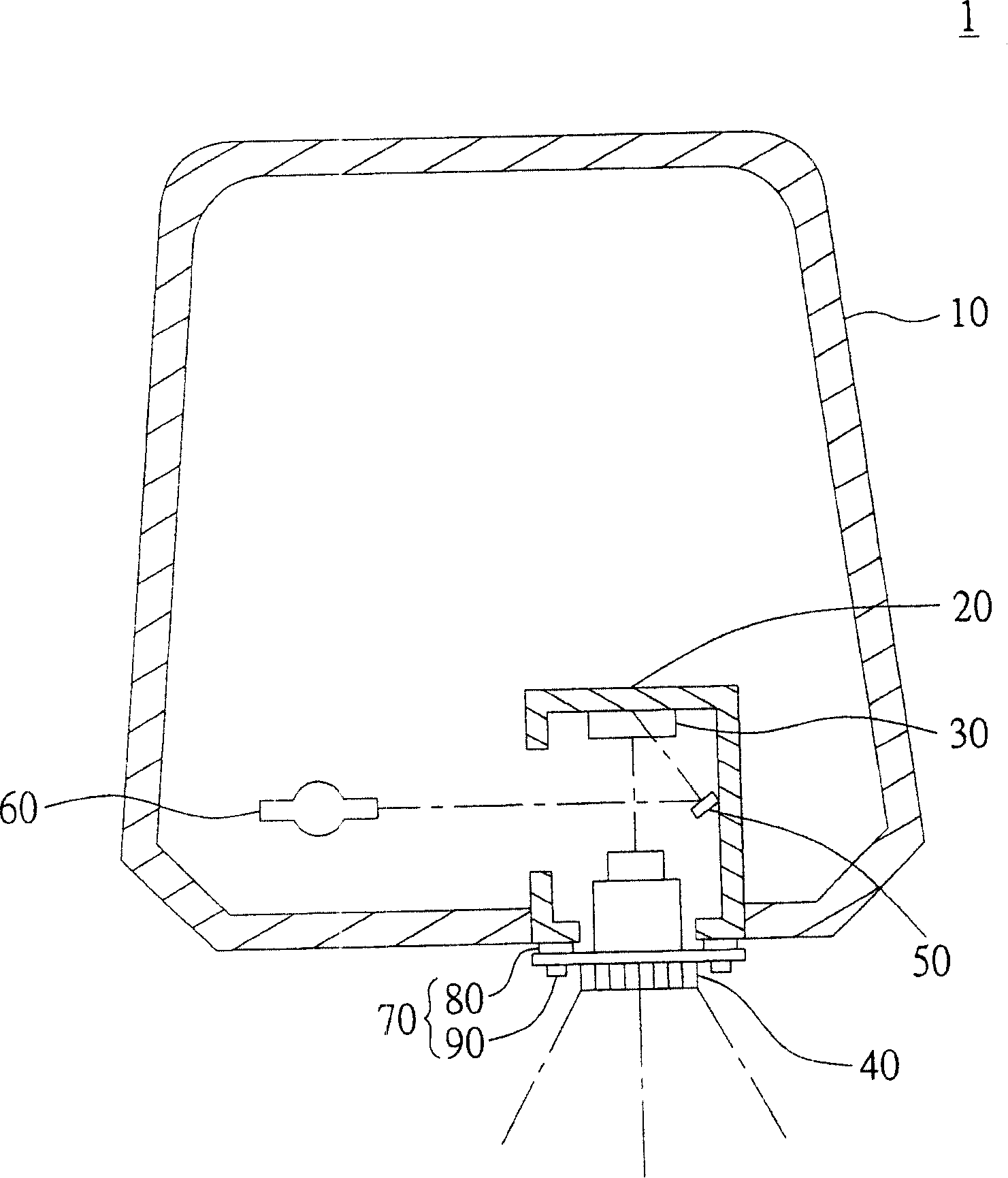

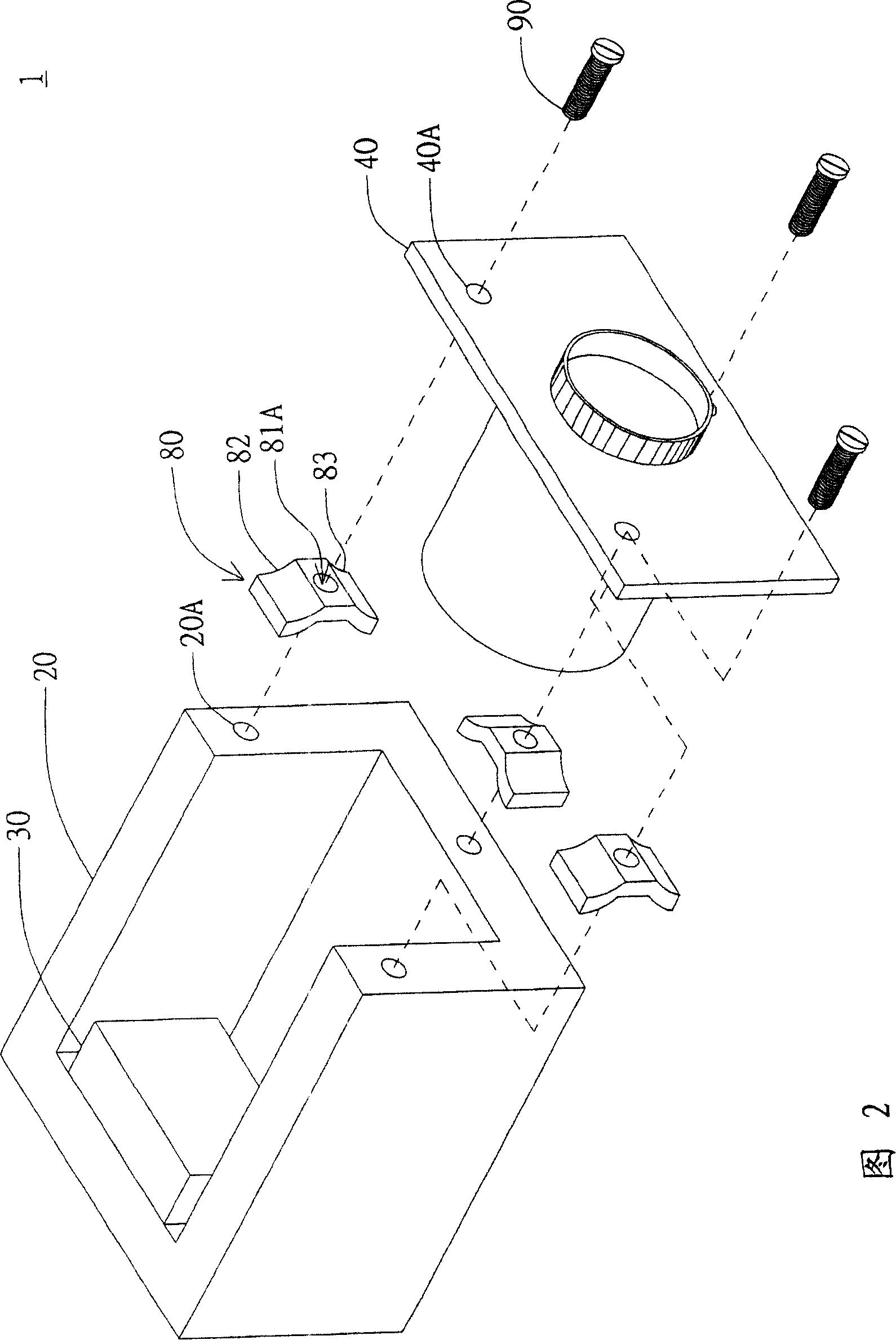

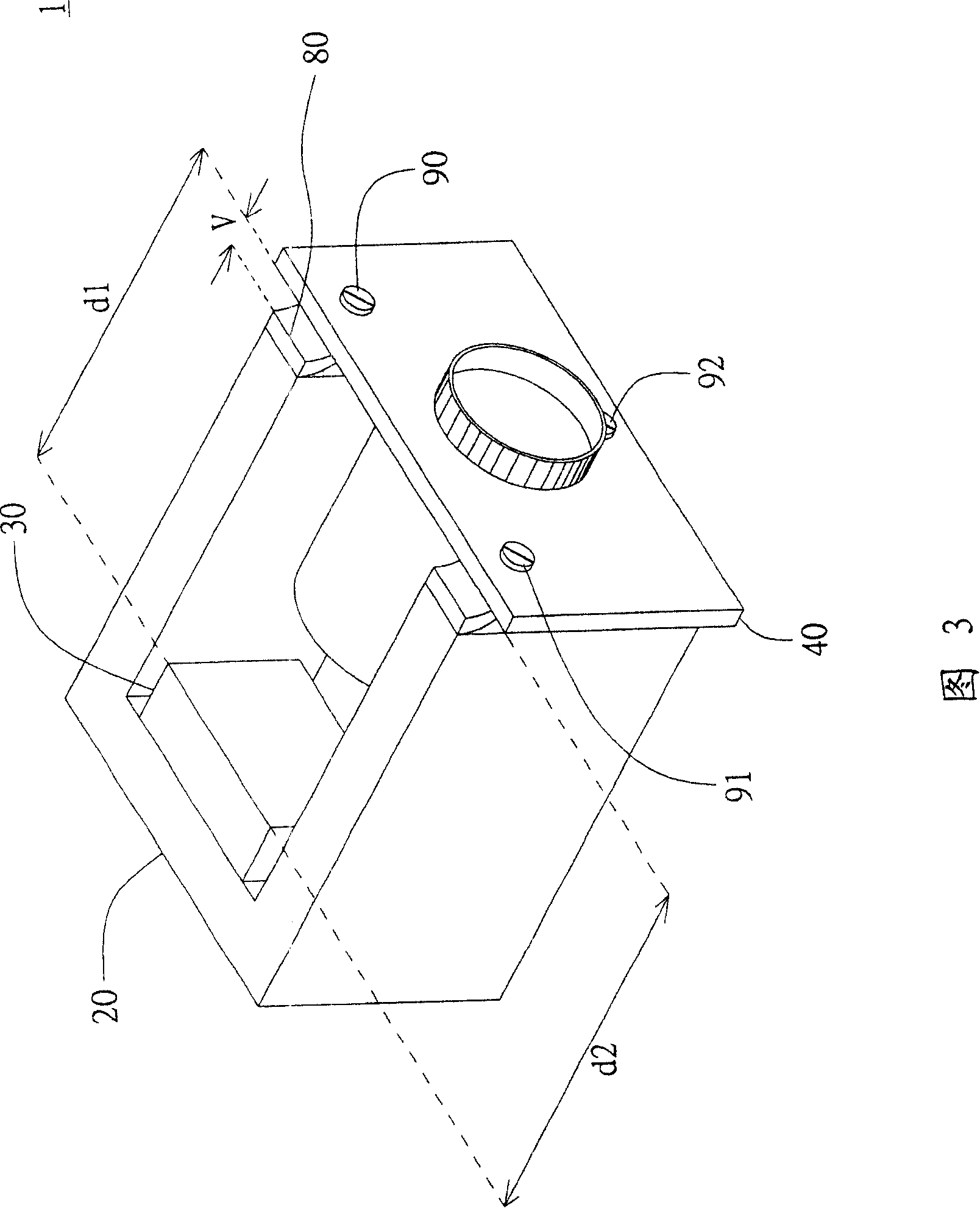

[0031] Please refer to figure 1 , which shows a schematic diagram of a projection device according to a preferred embodiment of the present invention. Such as figure 1 As shown, the projection device 1 includes a casing 10 , an optical-mechanical casing 20 , a first optical module 30 , a second optical module 40 , a reflector 50 , a bulb 60 and a fine-tuning structure 70 . The optical-mechanical casing 20 and the light bulb 60 are disposed in the casing 10 . The first optical module 30 , the second optical module 40 , the reflector 50 and the fine-tuning structure 70 are disposed on the optical-mechanical housing 20 . Wherein, the light bulb 60 is used to generate light, which is reflected by the reflector 50 , and then passes through the first optical module 30 and the second optical module 40 in order to project an image from the second optical module 40 onto the screen. The fine-tuning mechanism 70 is arranged on the optical-mechanical housing 20 to adjust the distance b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com