Uses of acetone air-sensitive material

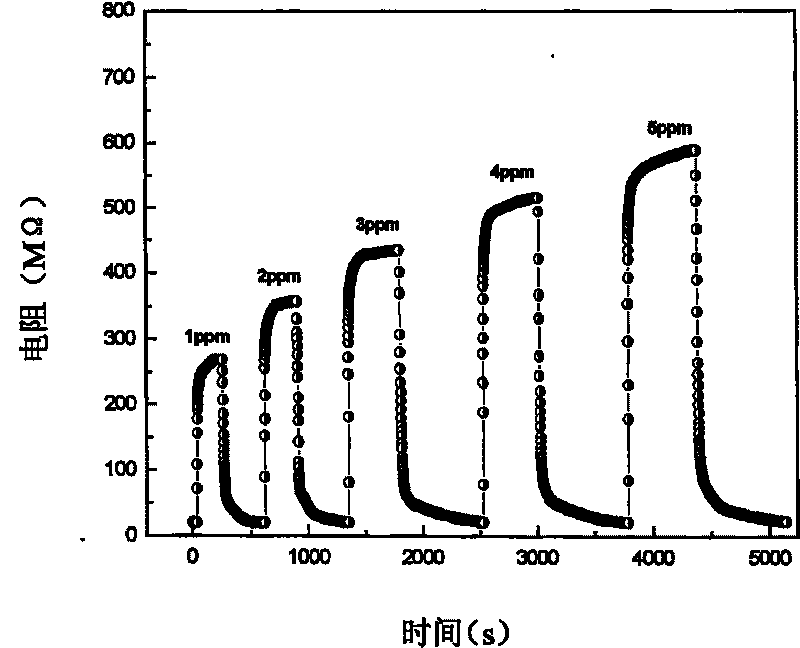

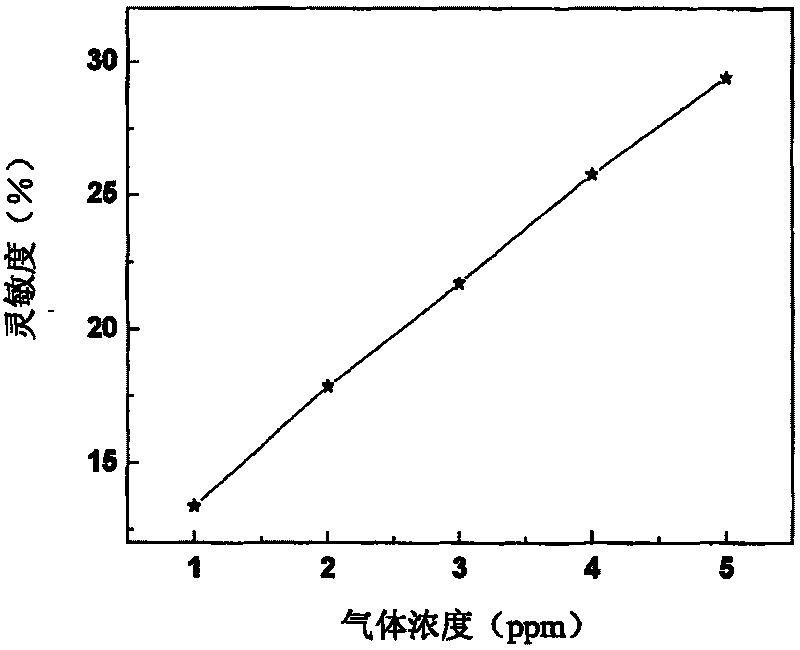

A technology of acetone gas sensing and sensitive components, which is applied in the direction of material analysis, material analysis by electromagnetic means, electrical components, etc., can solve the problems of selective response of acetone gas, high minimum detection limit of acetone, etc., and achieve good selectivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

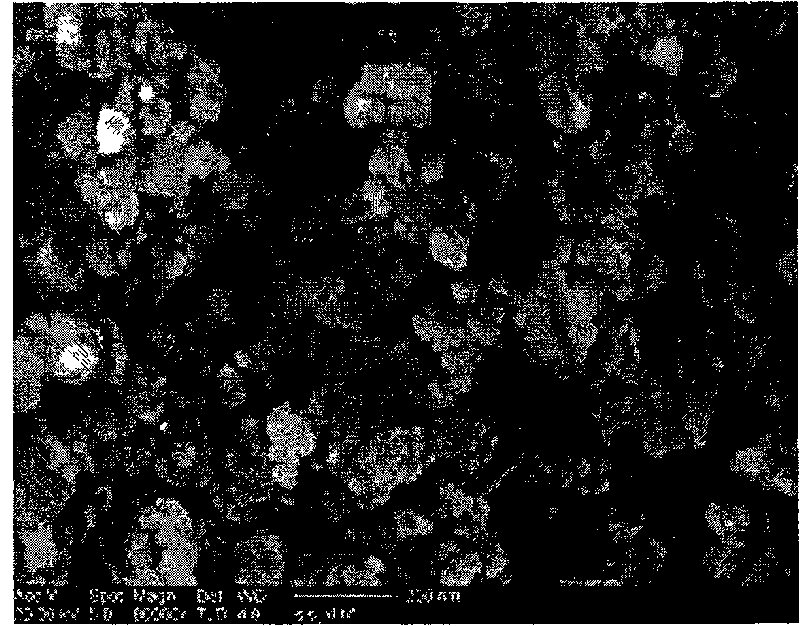

[0011] Specific embodiment one: the general formula of acetone gas sensitive material in the present embodiment is A 1-x A' x B 1-y B' y o 3 , where A is La or Nd, A' is Sr, Sm, Ce or Pb, B is Cr, Ni, Fe or Co, B'=Ti, Mn, Mg or Cu, x and y are different from 0 or 1 and When one of x and y is 0, the other is not 1.

[0012] The material in this embodiment is synthesized by thermal decomposition of amorphous citrate precursor

specific Embodiment approach 2

[0013] Embodiment 2: This embodiment is different from Embodiment 1 in that A is La. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0014] Embodiment 3: This embodiment is different from Embodiment 1 in that A is Nd. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com