Optical element and method for recording beam parameters, comprising a temperature sensor provided in the form of a pixel matrix

A technology of temperature sensor and optical element, applied in the field of optical element

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

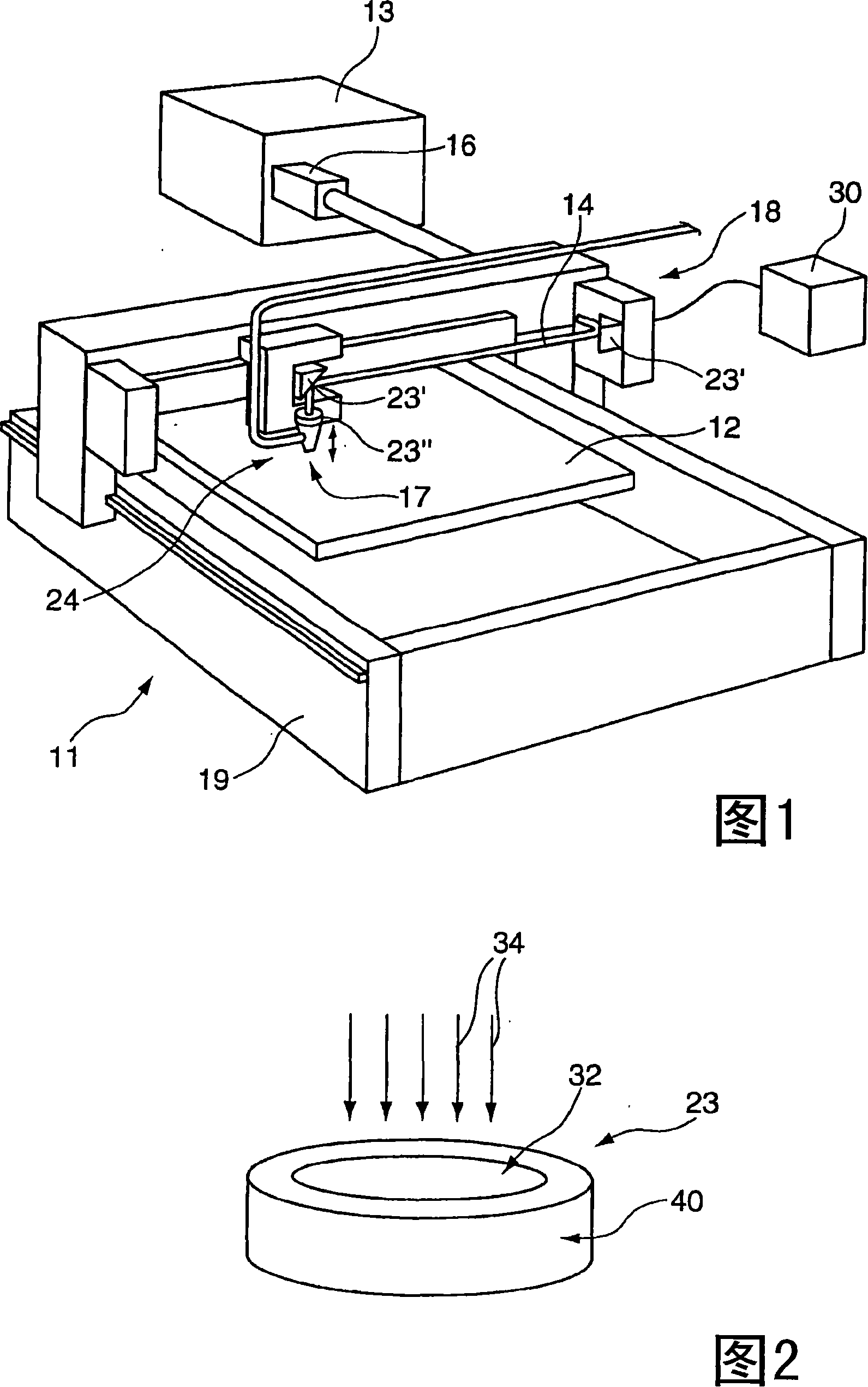

[0037] FIG. 1 shows a laser system 11 , for example a laser system for processing materials and workpieces 12 . The laser system 11 includes a laser device 13, especially a CO 2 A laser device of a laser that generates electromagnetic radiation, in particular a laser beam 14 . The wavelength of the laser beam 14 is preferably in the far infrared range. A beam telescope 16 is arranged on the laser device 13 via which the laser beam 14 generated in the laser device 13 is coupled out. Laser beam 14 is guided from beam telescope 16 to processing location 17 via external optical unit 18 . The external optical unit 18 is arranged on a machine base 19, which is designed to be single-axis or multi-axis according to the application. In this exemplary embodiment, the external optical unit 18 moves in X, Y and Z directions. Single-axis or multi-axis optical units are also referred to as floating optical units. Alternatively, the workpiece 12 and / or the optical unit 18 can also be mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com