Automatic-controlled friction and abrasion performance testing machine

A wear performance and testing machine technology, applied in the field of inertial testing machines, can solve the problems of small speed, small inertia, unsuitable for thermal shock braking test, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

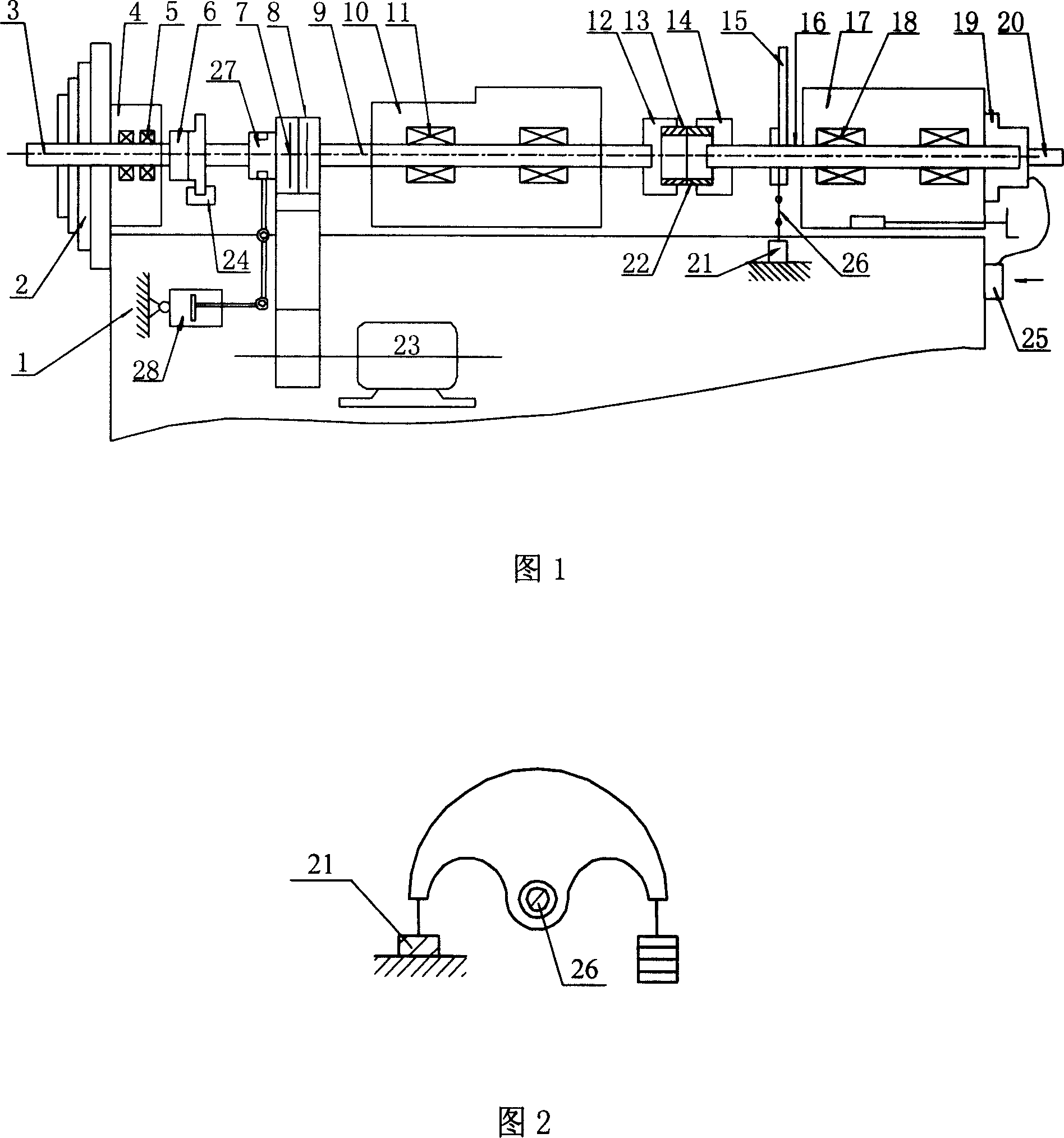

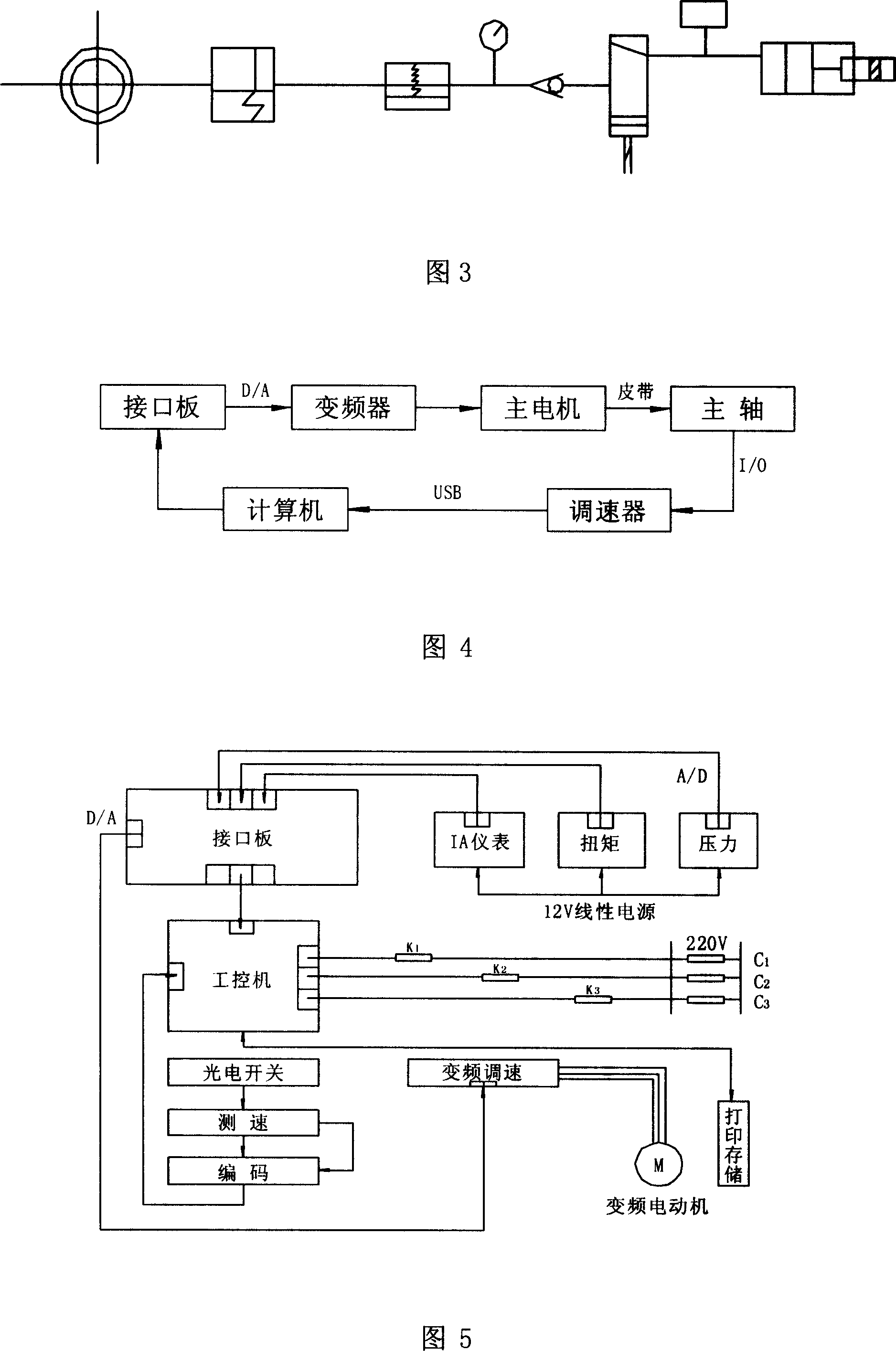

[0031] Referring to accompanying drawing 1, Fig. 1 is the overall structure schematic diagram of the present invention; The present invention has carried out system transformation to former MM1000 type friction testing machine, makes it adapt to the requirement of full-automatic control, reaches the consistency of test data and good repeatability Brand-new equipment; its structure includes bed 1, inertia disc 2, main motor 23, clutch 7, cylinder 19, etc., and constitutes the force application mechanism, clutch separation mechanism, torque measurement mechanism, temperature measurement device, etc. of the testing machine, so that in the experiment The friction and wear properties of materials were measured. The present invention adopts a non-resistance cylinder block, a pneumatic clutch mechanism, a return disc type force measuring mechanism, etc., all of which perform actions, and the clutch separation is automatically performed by a pneumatic mechanism. Tension sensor, the ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com