Sensor assembly for optically detecting the edges of a product and width-measurement method

A sensor device and optical detection technology, applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problem of large size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

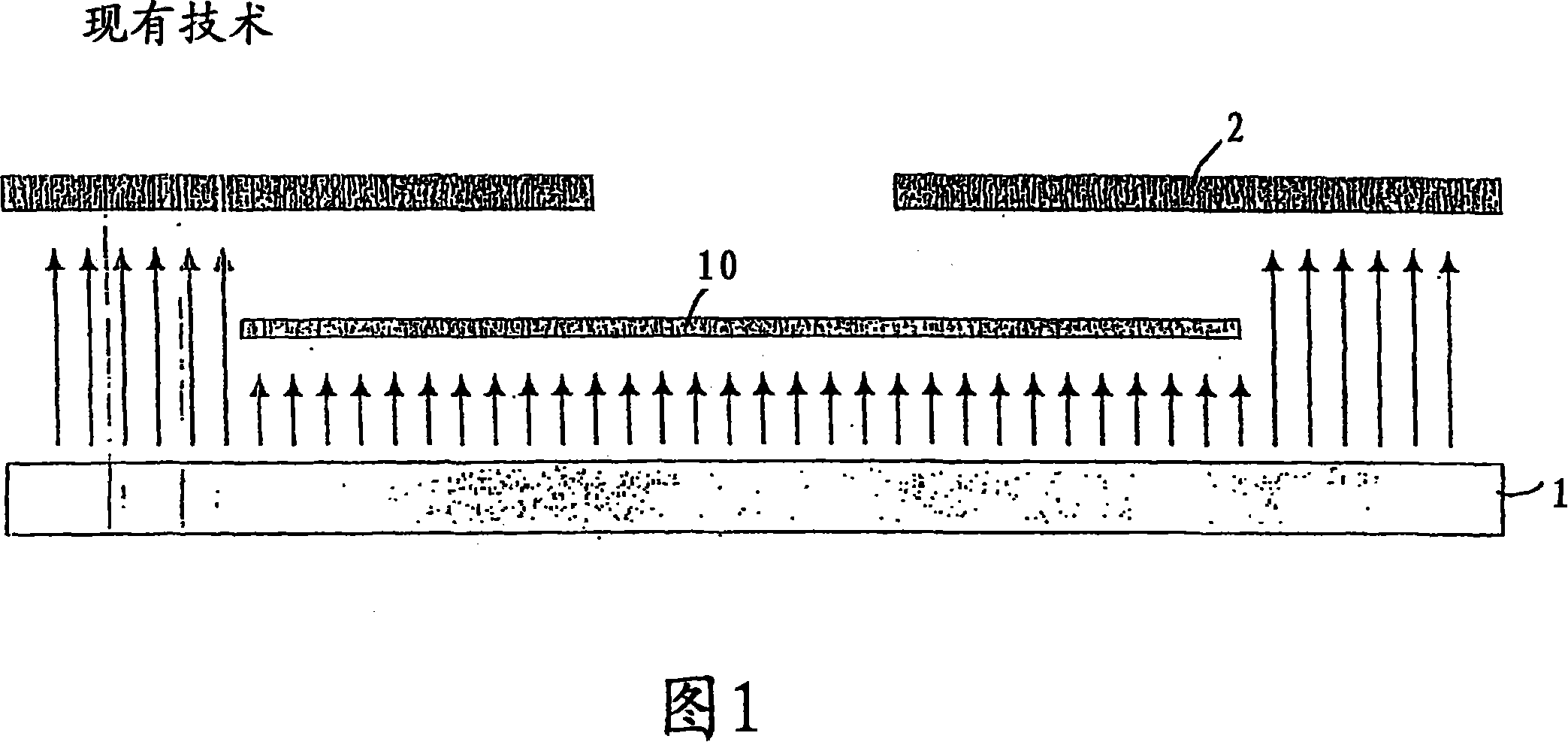

[0031] Figure 1 shows a conventional broadband sensor in a transmissive configuration according to the prior art. The rod-shaped light source 1 , such as a fluorescent lamp, emits light of any wavelength. The light is received by the light-guiding rod 2 and guided to a photosensor not shown in the figure, where it is recorded. The light-tight product 10 partially shades the rod-shaped light source. A light guide device not shown in the figure, such as a movable aperture or a rotating drum with a spiral split aperture, fades the light beam from the light source and moves it in the horizontal direction. The position of the light guide in which the first light signal in the light guide rod is no longer recorded marks the edge position of the product. When the positions of the two edges are known, the product width is correspondingly determined by measuring the difference between the two edge positions in the scale of the sensor device. Such an arrangement requires a precise al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com