Backlight module manufacture method

A technology of backlight module and manufacturing method, applied in chemical instruments and methods, optics, nonlinear optics, etc., can solve problems such as multiple time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the drawings and specific embodiments.

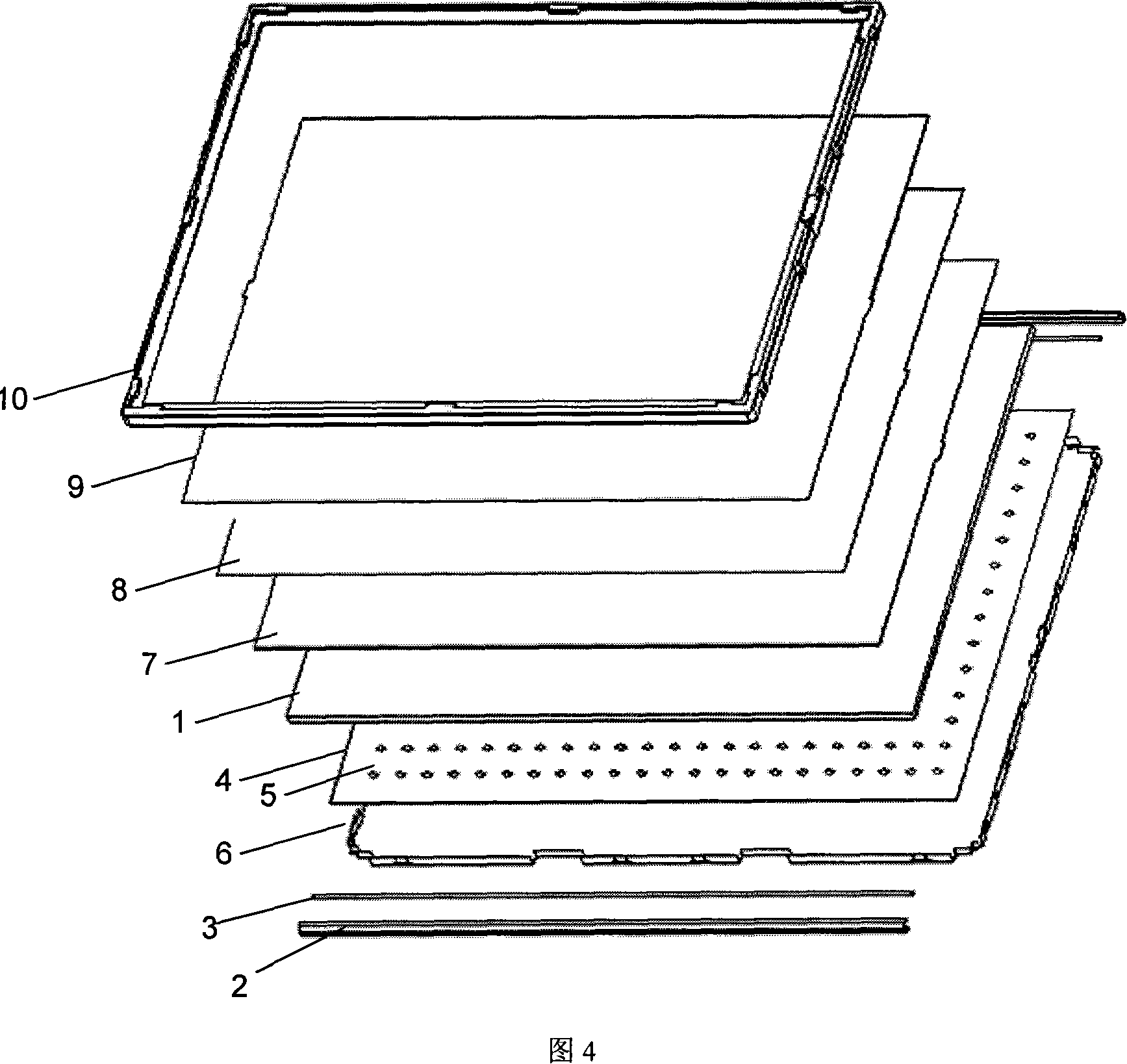

[0023] 3 and 4 show a backlight module containing two cold cathode lamp tubes, and the thickness of the light guide plate 1 is 4 mm. It consists of a light guide plate 1, two lamp tube reflectors 2, two lamp tubes 3, a reflection sheet 4, a back plate 6, a lower diffusion sheet 7, a prism sheet 8, an upper diffusion sheet 9 and a plastic frame 10. Different from the traditional process, when making the light guide plate, the light guide dots are not printed on one side surface of the light guide plate, but the light guide dots 5 are printed on one side surface of the reflective sheet 4 with ink added with adhesive. (The cross-section is shown in Figure 3), and then cover it with release paper, and store or transport it for module assembly. When the backlight module is assembled, the release paper is torn off and the side of the reflective sheet 4 with the light...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com