Vehicle window drive clamping-proof control system

A technology for car windows and switches, applied in windows, vehicle parts, door/window accessories, etc., can solve the problems of inability to use, inaccurate, and high cost, and achieve the effects of high anti-pinch precision, convenient use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

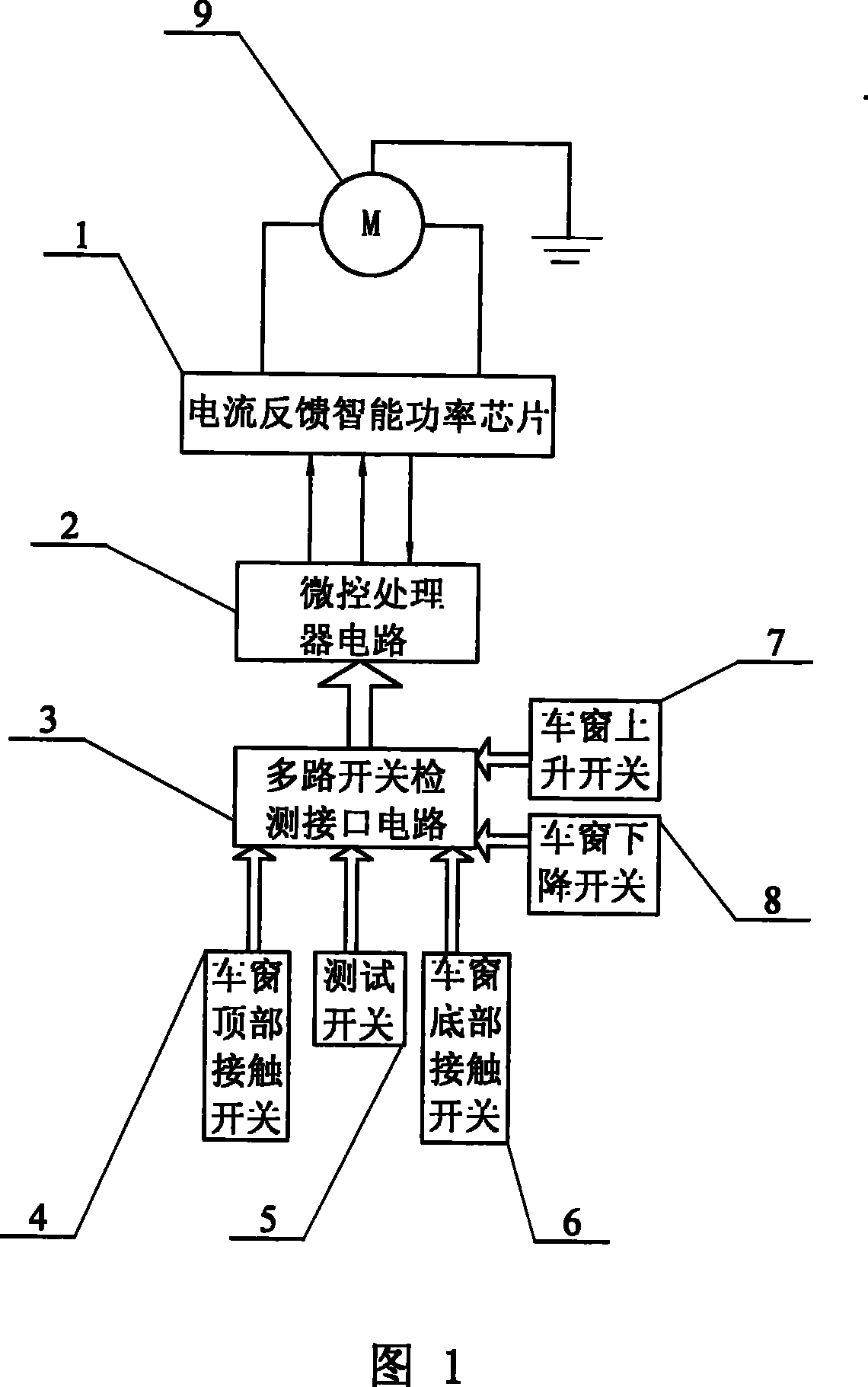

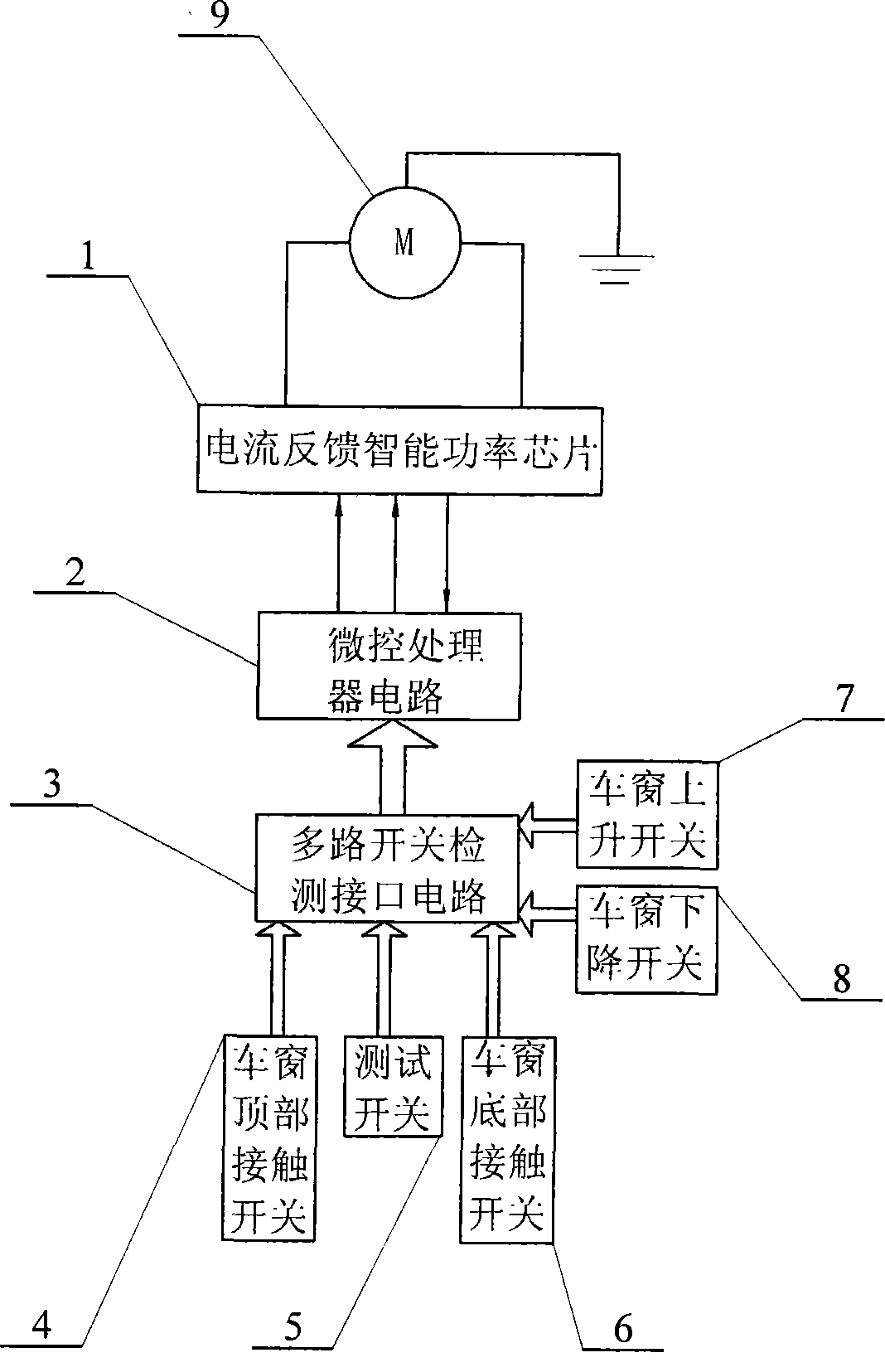

[0008] Specific implementation mode one: combine figure 1 This embodiment is described. This embodiment consists of a current feedback intelligent power chip 1, a micro-controller circuit 2, a multi-way switch detection interface circuit 3, a contact switch 4 at the top of the window, a test switch 5, a contact switch 6 at the bottom of the window, and Composed of window up switch 7 and car window down switch 8;

[0009] The forward rotation control input terminal of the current feedback smart power chip 1 is connected to the forward rotation control output terminal of the microcontroller circuit 2, and the reverse rotation control input terminal of the current feedback smart power chip 1 is connected to the reverse control output terminal of the microcontroller circuit 2 terminal, the motor current signal output terminal of the current feedback intelligent power chip 1 is connected to the motor current signal input terminal of the microcontroller circuit 2, and the switching ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com