Clay vibrating bunker

A vibrating hopper and clay technology, applied in vibrating conveyors, loading/unloading, conveyors, etc., can solve problems such as uneven feeding, blockage, and material accumulation at the outlet, and achieve the effect of smooth feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

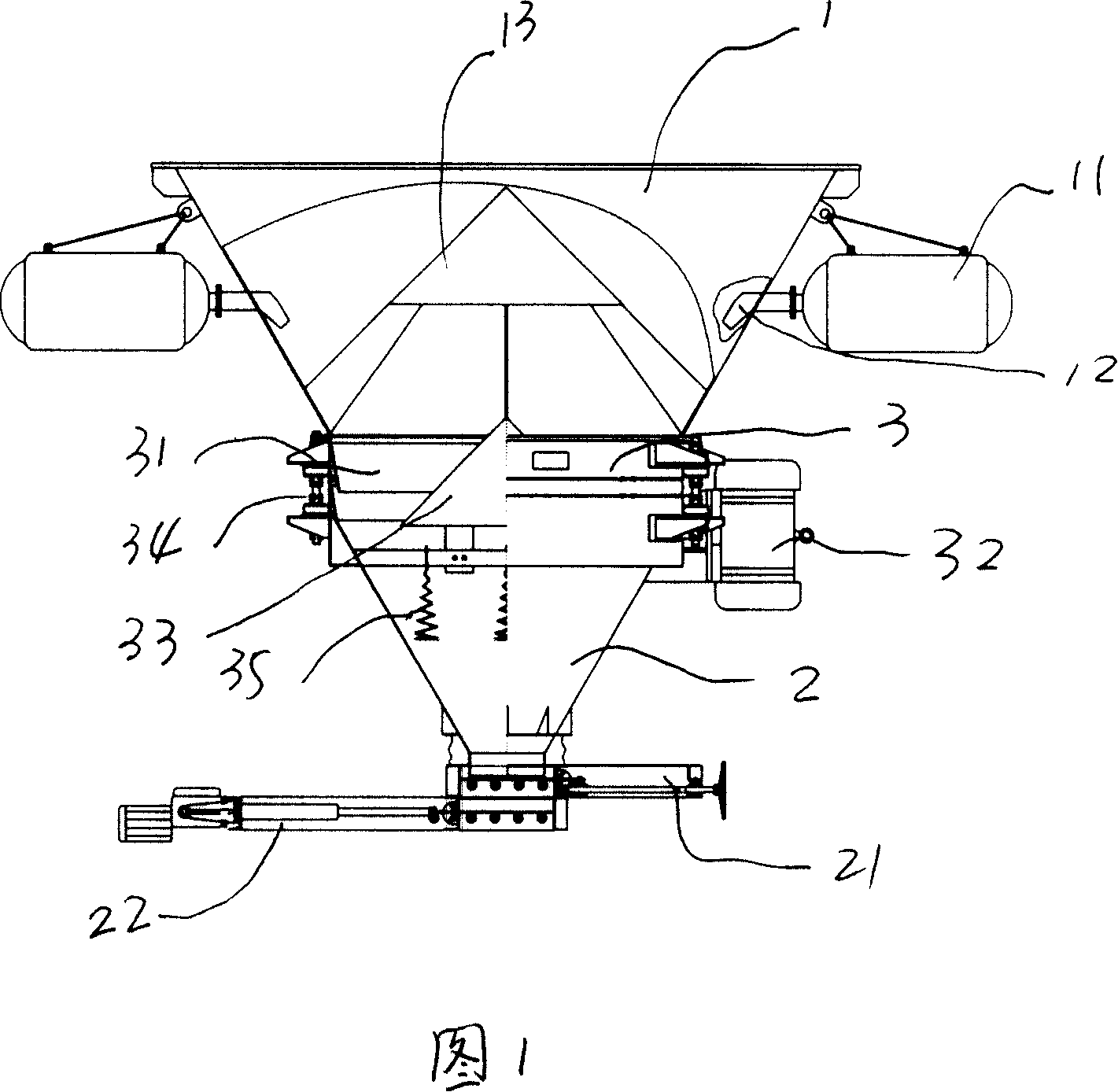

[0013] The clay vibrating hopper of the present invention will be further described below in conjunction with the accompanying drawings.

[0014] As shown in Figure 1, a vibrating hopper for clay comprises an upper cone 1 and a lower cone 2. The difference is that a vibrating device 3 is placed between the upper cone 1 and the lower cone 2. An air cannon 11 is provided, the nozzle 12 of the above-mentioned air cannon 11 is placed on the inner wall of the upper cone 1, the nozzle 12 of the above-mentioned air cannon 11 is tangent to the inner wall of the upper cone 1, and the lower part of the lower cone 2 is equipped with a manual valve 21 and an electric valve. The valve 22, the above-mentioned upper cone 1 is built with an upper cone decompression cone 13, so that the material enters the vibrating device along the inner wall of the cone.

[0015] Above-mentioned vibrating device 3 comprises vibrating hopper 31, vibrating motor 32, activation cone 33, and above-mentioned acti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com