Cyclone type dust-cleaning device cyclone

A technology of dust collector and cyclone, which is applied in the direction of the device where the axis of the swirl can be reversed, the swirl device, etc., can solve the problems of secondary dust resistance loss, low dust removal efficiency, inner wall wear, etc., to reduce secondary Reduce dust, reduce resistance, and reduce the effect of inner wall wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

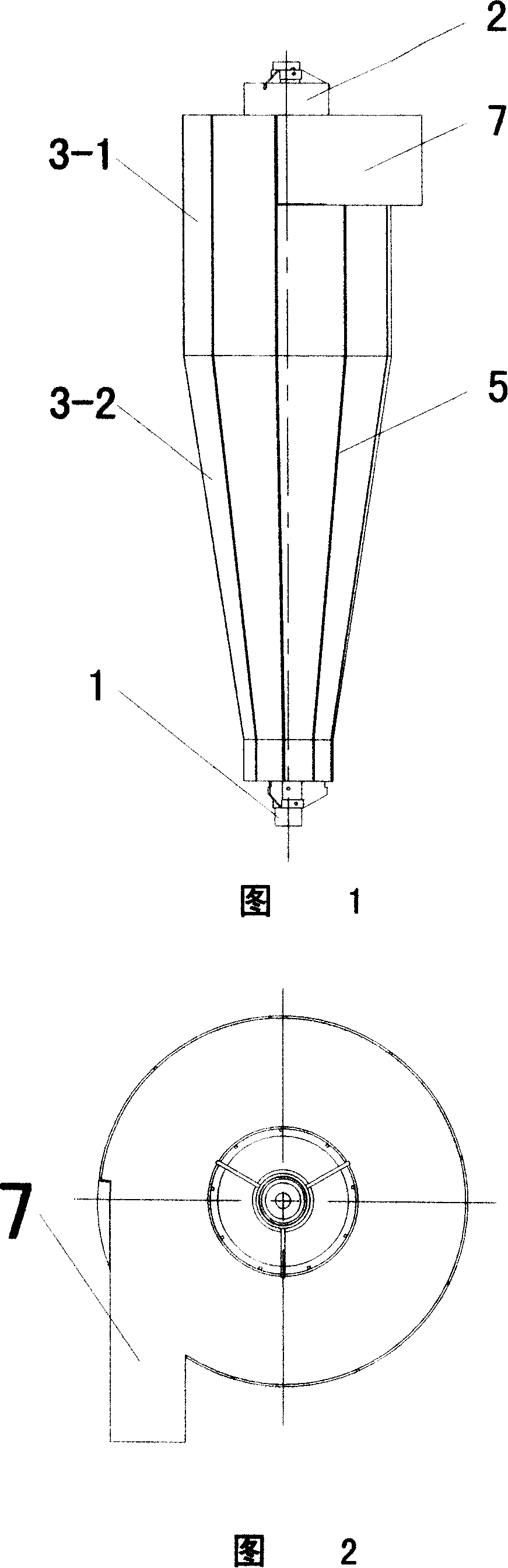

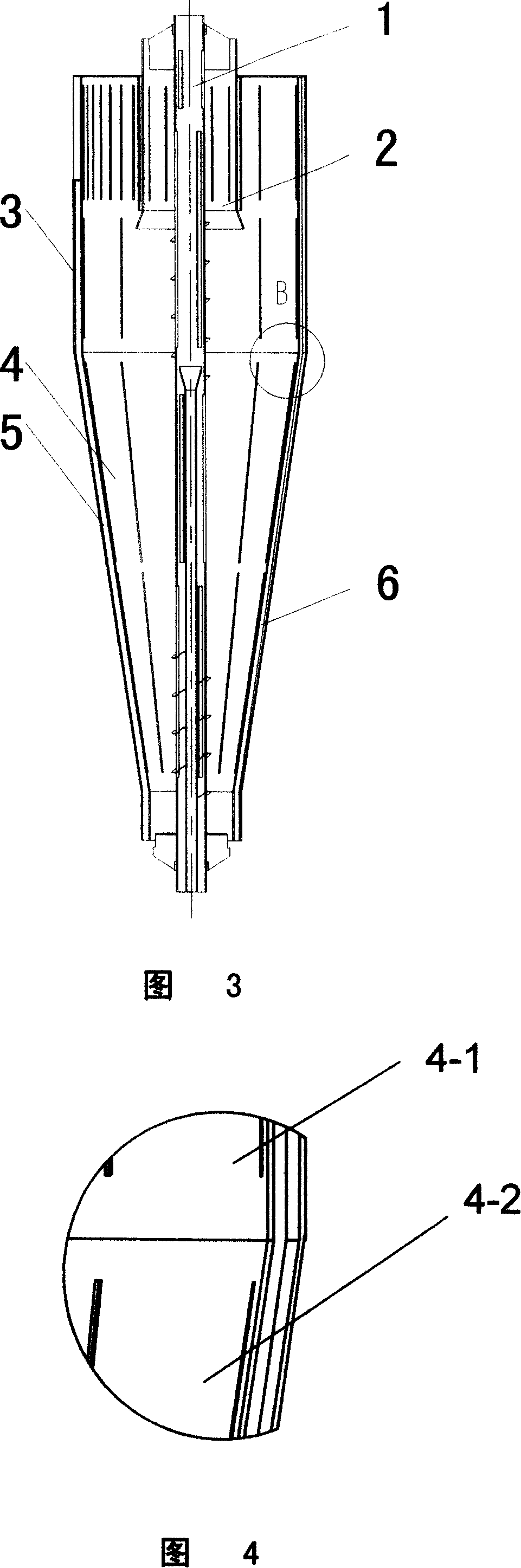

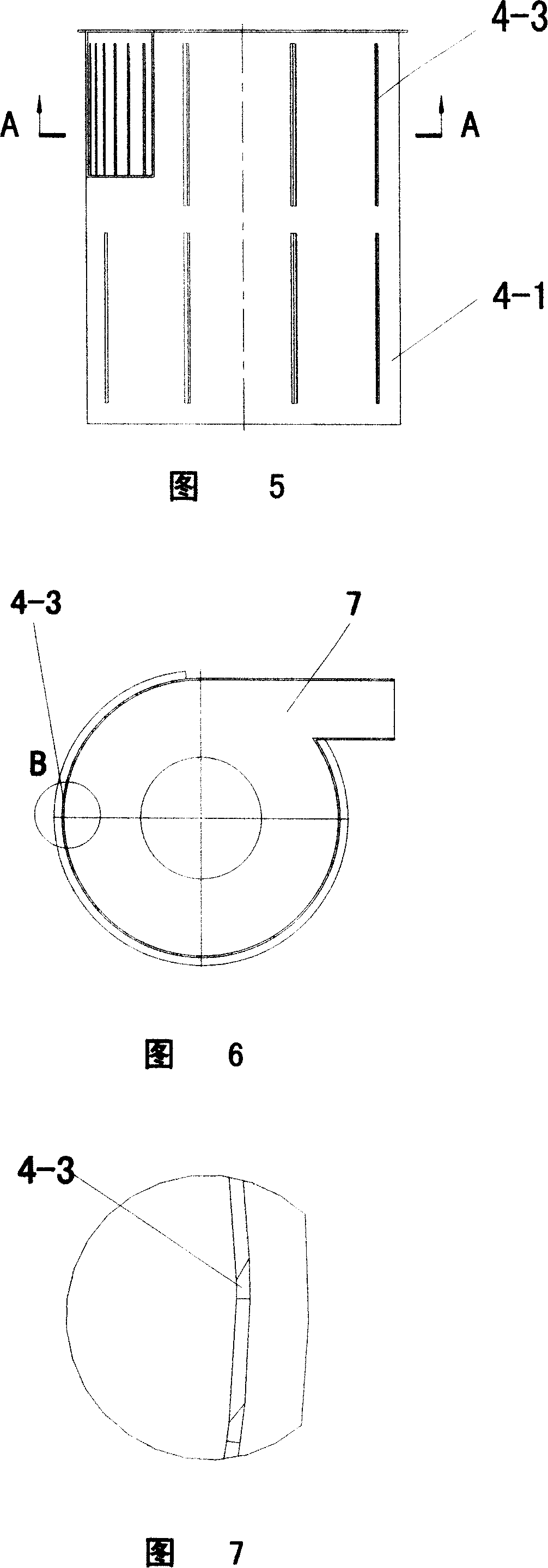

[0032] The cyclone of the cyclone dust collector as shown in the figure is a creative improvement to the cyclone of the existing similar cyclone dust collector. These improvements are mainly manifested in the following aspects:

[0033] First, a core tube assembly is installed in the center of the cylinder with interlayer;

[0034] Second, between the inner and outer cylinders, the supporting steel bars provided on the inner cylinder not only become the connecting member of the inner and outer cylinders, but also form a vertically arranged dust collection channel that runs through the upper and lower sides;

[0035] Its three, vertical slot holes are set up and down on the surface columnar cone of the inner cylinder body.

[0036] The cyclone of this cyclone type dust collector includes an outer cylinder 3 with a cylindrical shape connected to a cone, an inner cylinder 4 with a tangential air inlet 7 on the upper part, and an exhaust pipe located at the upper center of the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com