Lens protecting cover module

A protective cover and lens technology, applied in optics, instruments, camera bodies, etc., can solve the problems of a large number of modules, complex driving methods and structural design, and lack of market competitiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

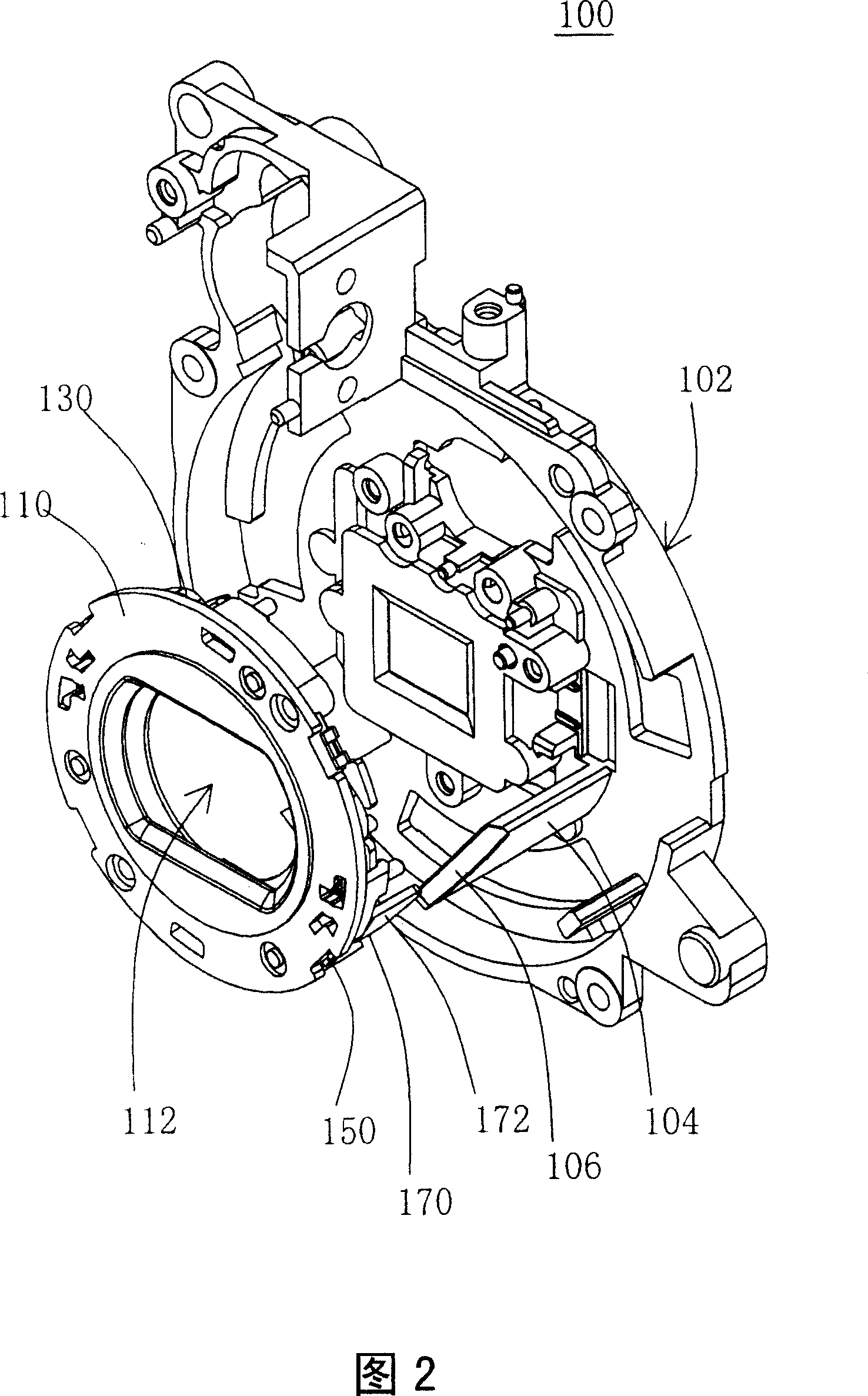

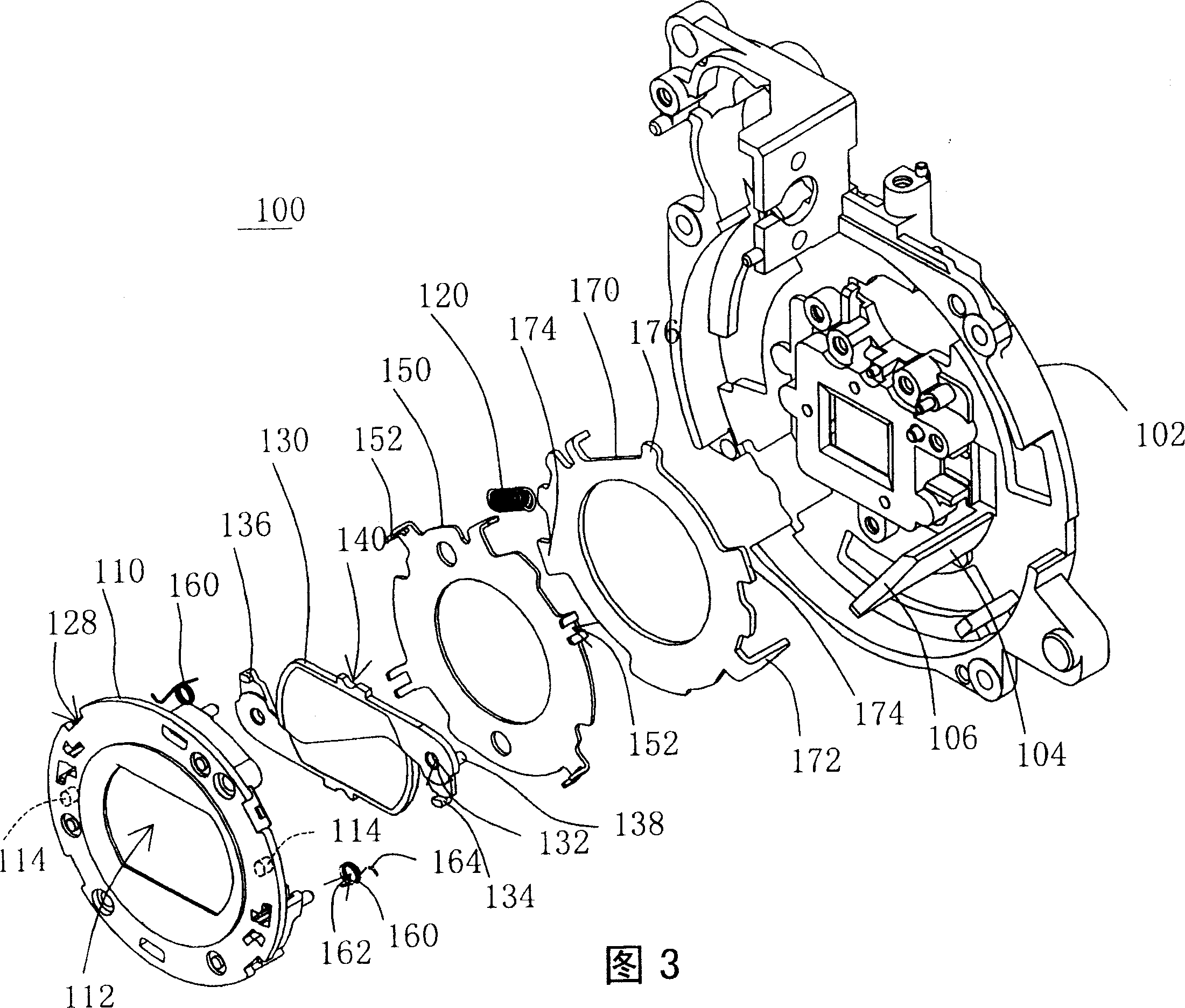

[0041] As shown in Fig. 2 and Fig. 3, it is a three-dimensional and exploded view of the present invention. The lens protection cover module 100 of the present invention includes: a front substrate 110 , a fixing plate 150 , at least one protection cover 130 , a driving plate 170 and an interference component 104 . The front substrate 110 has a mirror hole 112 . A lens group (not shown) disposed between the protective cover 130 and the lens base 102 captures an external light source through the mirror hole 112 to form an image. The fixing plate 150 is connected to a first elastic component 120 . In addition, the fixing plate 150 and the front base plate 110 are fixed relative to the protective cover 130 ; the fixed here means that there is no relative rotation between the two after the assembly is completed. The protective cover 130 has a pivot 114 and a lever 138 . The pivot 114 is located between the front base 110 and the fixing plate 150 so that the protective cover 130 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com