Method for producing N-ethyl butyl amine by pipe reaction and device thereof

A technology of ethylbutylamine and production method, applied in chemical instruments and methods, preparation of amino compounds, preparation of organic compounds, etc., can solve the limitations of operability and/or economy, low product yield, environmental pollution and other problems, to achieve the effect of easy large-scale production, good product quality, and easy control of reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

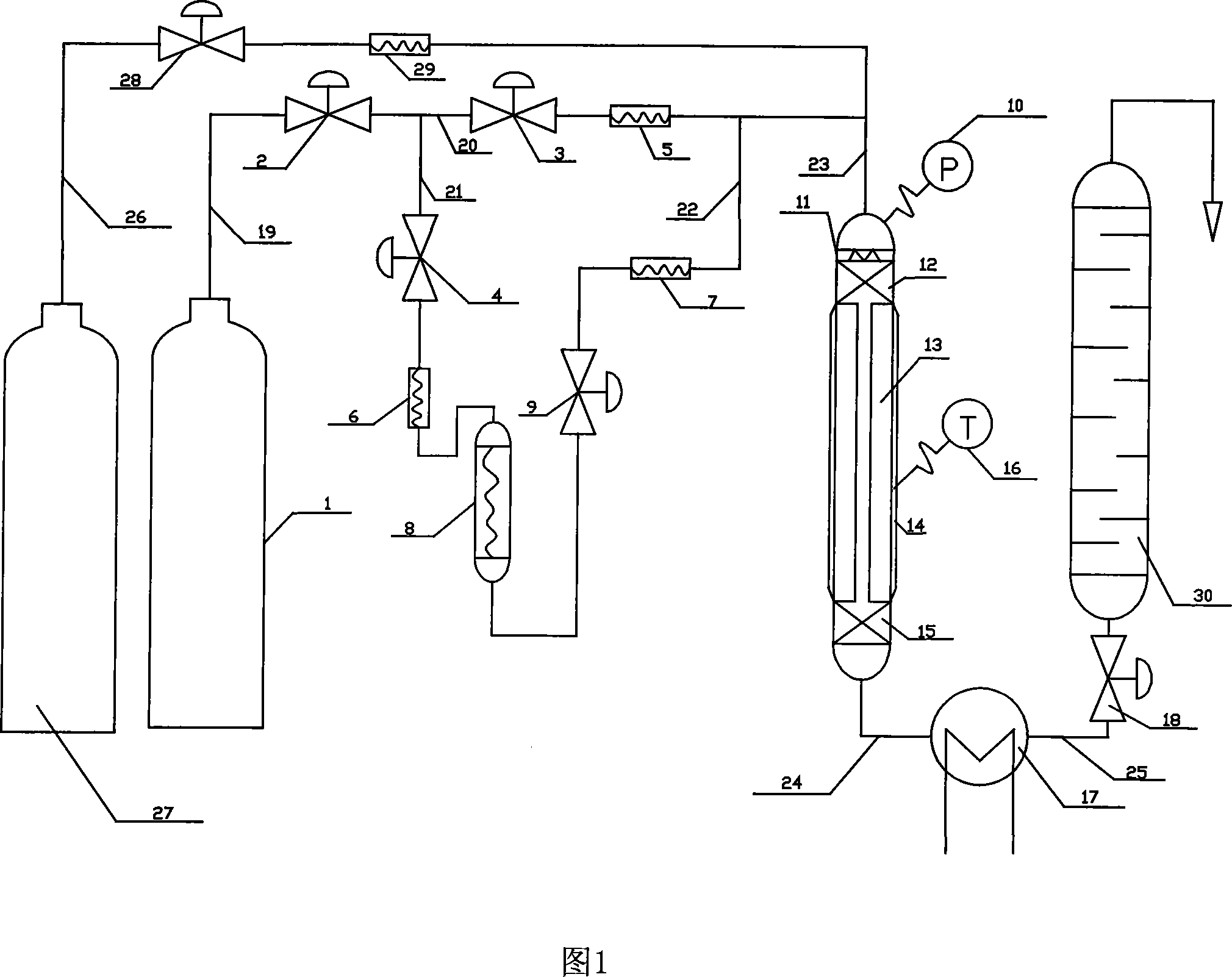

Image

Examples

Embodiment 1

[0047] Embodiment 1, the production method of N-ethylbutylamine of the present invention, then carry out following steps successively:

[0048] 1), close stop valve 28, make stop valve 3,4,9,18 be in open state; Add n-butanol 88g (1mol) respectively in metering tank 8, ethylamine 90g (2mol), form mixed solution;

[0049] 2), the H in the high-pressure gas storage tank 1 2 After passing through the pipeline 19, it enters the pressure reducing valve 2 for decompression treatment. The pressure value set by the pressure reducing valve 2 is the working pressure in the following aminolysis reaction. A part of H from pressure reducing valve 2 2 Directly through line 20 to header 23, H 2 The flow rate is controlled by flow meter 5. Another part of H from pressure reducing valve 2 2 Enter the metering tank 8 through the pipeline 21, this part H 2 The flow rate is controlled by flow meter 6; this part H 2 Push the mixed liquid in the metering tank 8 to flow to the collecting pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com