Device for positioning the trailing edge of sheets

A sheet and edge technology, applied in the direction of positioning objects, transportation and packaging, sending objects, etc., can solve the problem that the role of the guide roller is no longer enough, heavy weight, etc., to achieve the effect of avoiding the rebound of the sheet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

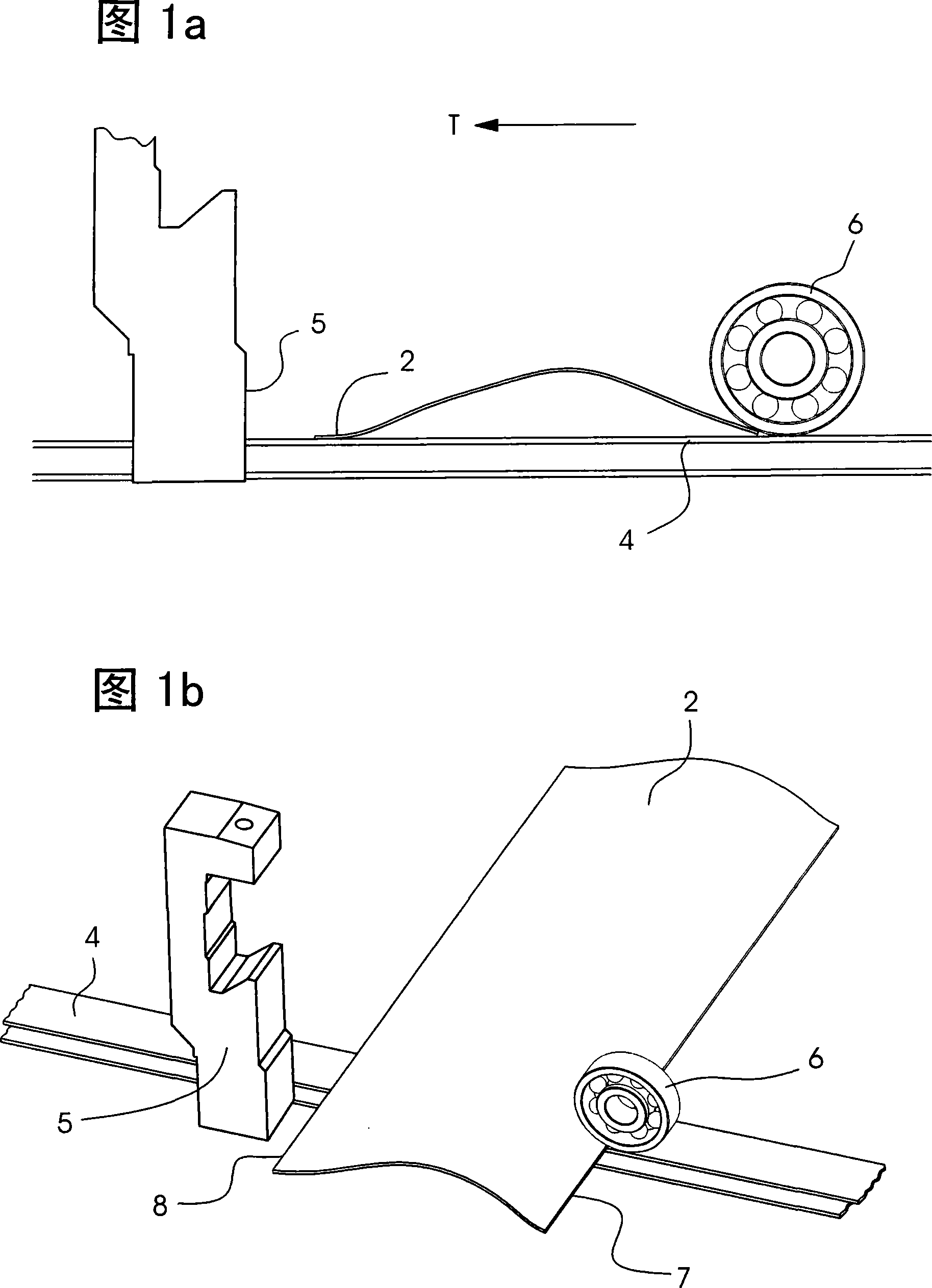

[0027] The principle structure of a device according to the background art is shown in FIGS. 1 a and 1 b.

[0028] The rollers 6 push the sheets 2 together with the conveyor belt 4 against the stop 5 . The sheet 2 stop deforms like a spring and then releases the stored energy as a spring force against the conveying direction. The wedge formed between the roller 6 and the belt 4 is intended to brake the sheet.

[0029] The rollers 6 used today for improved sheet transport and without marking are very flexible and have a very low mass. These advantages during sheet transport are disadvantages during sheet braking. The spring-backed sheet 2 bulges and jacks up the roller 6 . Since the rollers 6 have almost no rolling resistance and no mass, the direction of rotation is now reversed. Sheet 2 is braked only by rolling friction. The strong pressing force of the rollers 6 to prevent the lifting often causes marks on the sheet 2 . These traces are not desired and should be avoid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com