Inverse thermal acoustic imaging part inspection

A part and part feature technology, applied in the field of reverse thermoacoustic imaging parts inspection, can solve the problems of inconspicuous parts failure and difficult detection of small cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

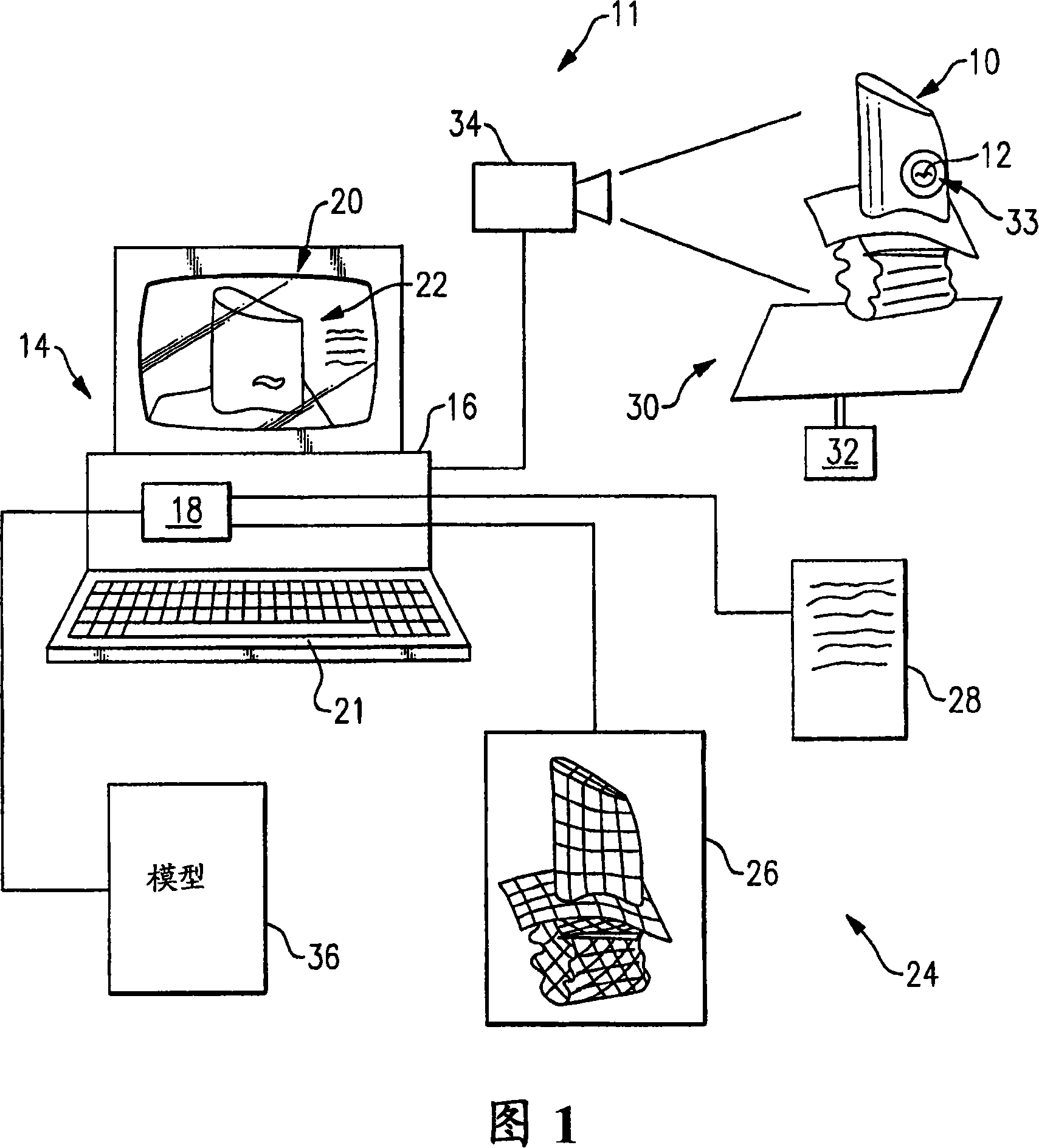

[0009] An inspection system 11 for identifying characteristics, such as defects, in a part 10 is shown in FIG. 1 . The inspection system 11 can be fully automated. The part 10 with the defect 12 is mounted on a vibration device 30 which is excited using a plurality of actuators 32 at different frequencies. The vibrating device 30 may be a shaking table or an ultrasonic device capable of vibrating the part 10 in the range of, for example, 500 Hz-100 kHz.

[0010] Due to the vibrations exerted on the part 10 by the vibrating means 30, heat is generated at any defect or crack in the part 10 due to friction and plastic deformation during each loading cycle. This heating, shown schematically at 33 , causes a temperature rise above the nominal structural temperature of the part 10 . The temperature rise caused by the crack is distributed over a wider range than the strain distortion, and thus can be detected using the infrared camera 34, for example. Images of the exterior of par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com