Copper flash smelting operation parameter optimization method

A technology of flash smelting and operating parameters, applied in flow control, non-electric variable control, instruments, etc., can solve the problems of deviation between the mechanism model and the actual system, difficulty in ensuring the accuracy of the mechanism model, and inability to effectively ensure the stability of control variables.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

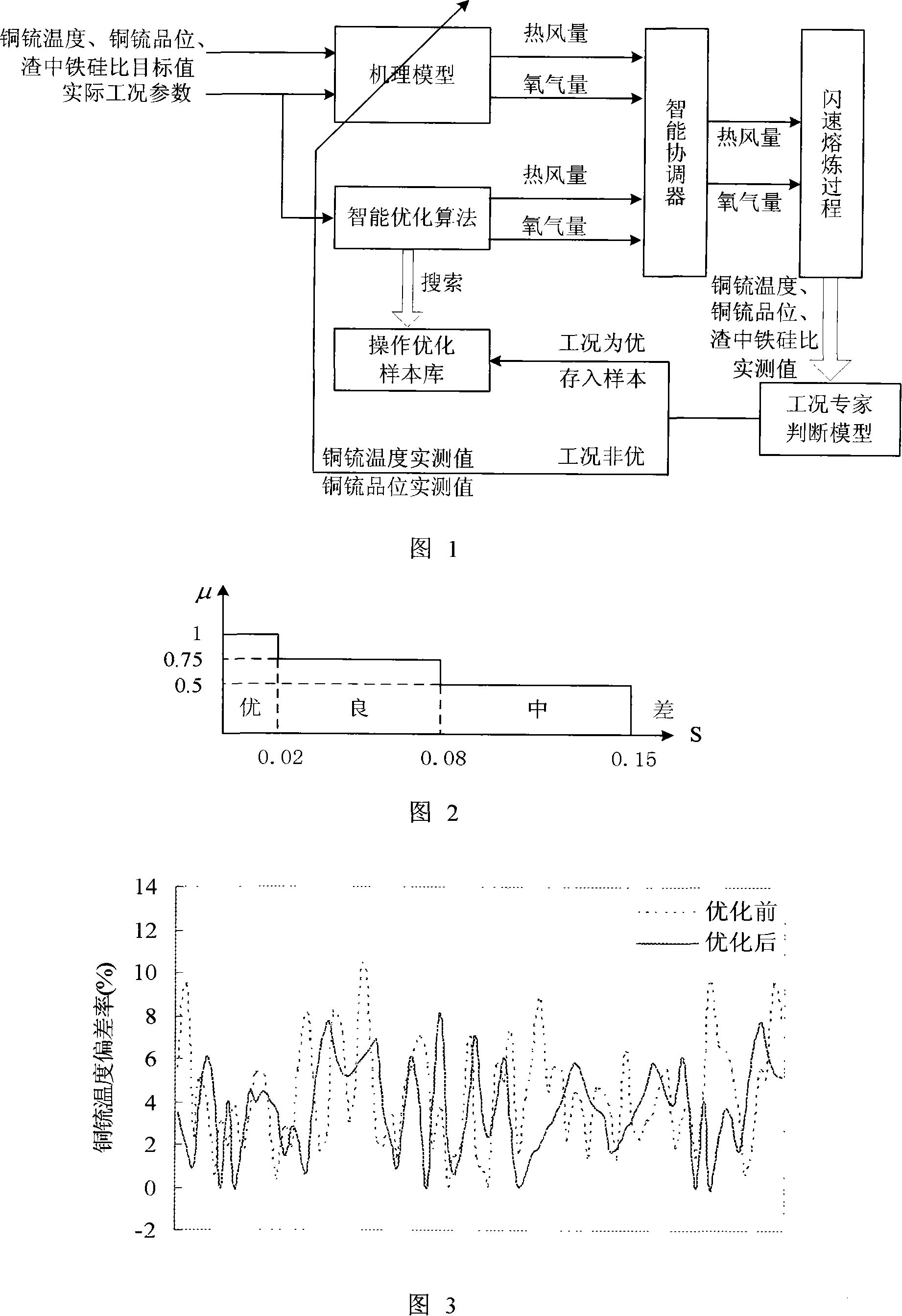

[0013] As shown in Fig. 1, the present invention uses a mechanism model and an intelligent optimization model to optimize the operating parameters respectively, and then integrates the two groups of optimization results through an intelligent coordinator to obtain the final optimization result of the operating parameters. The optimization results are output to the flash smelting control system. After the flash smelting process, the actual measurement values of the three parameters of copper matte temperature, copper matte grade, and iron-silicon ratio in slag are judged by using the working condition judgment model: if the current comprehensive working condition If it is optimal, the current working condition parameters and operating parameters have just been stored in the operation optimization sample library; if the current working condition is not optimal, the mechanism model will be corrected by using the measured values of copper matte temperature and copper matte grade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com