Highly-ensured wind-resistant universal color-flame candle and preparation method thereof

A color-flame candle and a manufacturing method technology are applied in the field of high-protection and wind-resistant general-purpose color-flame candles and their preparation fields to achieve the effects of eliminating scattering phenomenon, improving utilization efficiency, and improving wind resistance performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

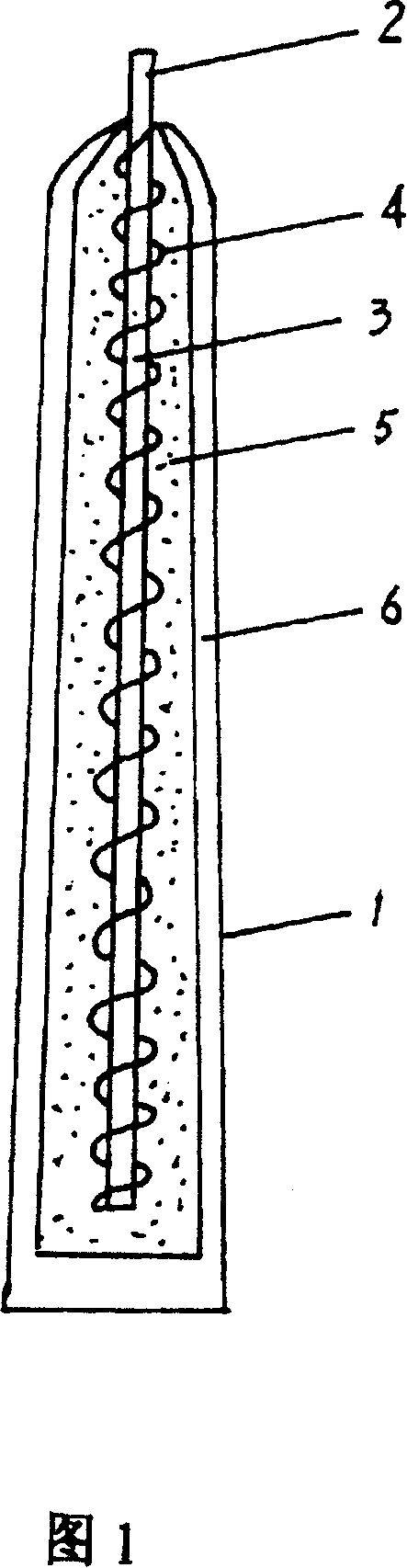

[0020] The accompanying drawing of the present invention is a structural schematic diagram of a general-purpose colorful flame candle with high protection and wind resistance.

[0021] The present invention is described in detail below in conjunction with accompanying drawing.

[0022] High-resistance and wind-resistant universal colored flame candle is composed of a candle body 1 and a candle wick 2 in the candle body. The candle wick 2 is composed of a main candle wick 3 and an excitation candle wick 4. Coarse multi-ply fiber yarn, generally 21 yarns, twisted into 8-30 strands, the excitation candle wick 4 is a thinner single-ply fiber yarn, 32 yarns per strand can be used, and the excitation candle wick 4 is spirally wound on the main candle wick 3 around, the pitch of the helical coil is 1-3 mm, and the screw diameter is 3-6 mm.

[0023] The candle body 1 is composed of a main burner 5 and a surface layer 6 , and the main burner 5 is covered by the surface layer 6 . The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com