Antifake bottle cap

A technology of anti-counterfeiting bottle caps and anti-counterfeiting rings, which is applied to prevent repeated filling of containers, locking devices, closing and other directions, and can solve the problems of no change of bottle caps, not being intuitive enough, and not being seen.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

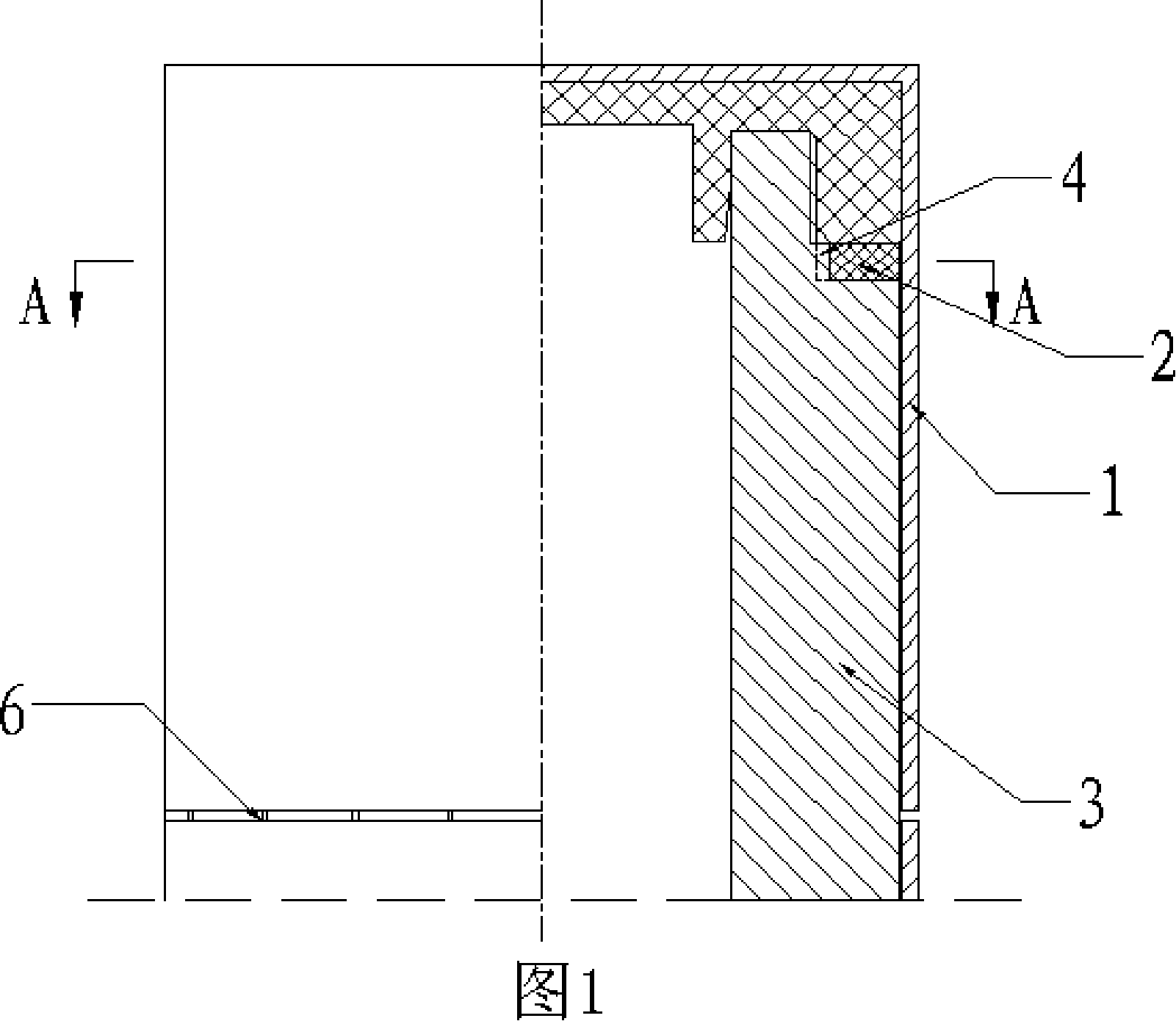

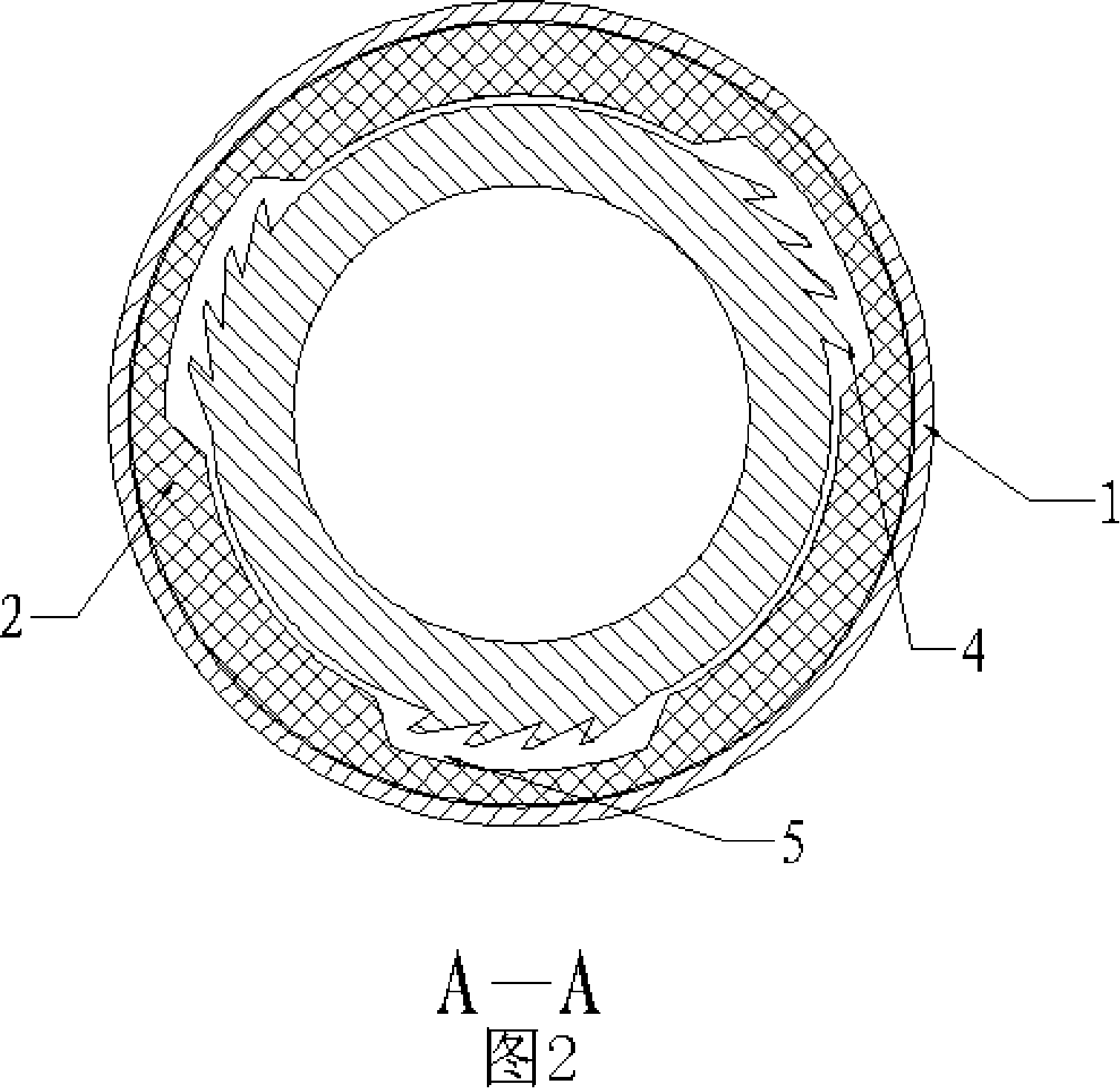

[0022] Embodiment: The bottle mouth 3 of the anti-counterfeiting bottle cap is fixed on the bottle body, and an opening is provided on the top of the bottle mouth 3 for the liquid in the bottle to flow out. The outer cover 1 is fixed on the bottle mouth 3, and the opening of the bottle mouth 3 is sealed, the most commonly used is to fasten by thread, and to open the outer cover 1, just rotate the outer cover 1. In order to prevent the outer cover 1 from being unscrewed at will, the bottom of the neck of the outer cover 1 is fixed on the bottle mouth 3, and a layer of connecting ribs 6 is arranged on the lower part of the outer cover 1 neck. An anti-counterfeit ring 2 is fixed on the outer cover 1, and cooperates with the ratchet 4 on the bottle mouth 3. When the outer cover 1 of the bottle cap needs to be opened, the connecting rib 6 on the outer cover 1 needs to be twisted off or cut off with other items, and then the outer cover 1 is unscrewed. When the outer cover 1 is uns...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com