Deposition molded product, deposition molding method, and deposition molding apparatus

A film-forming device and forming body technology, which is applied to lighting devices, fixed lighting devices, lighting device components, etc., can solve the problems of large number of processes, labor and time consumption, poor yield rate, etc., and achieve good reflection efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

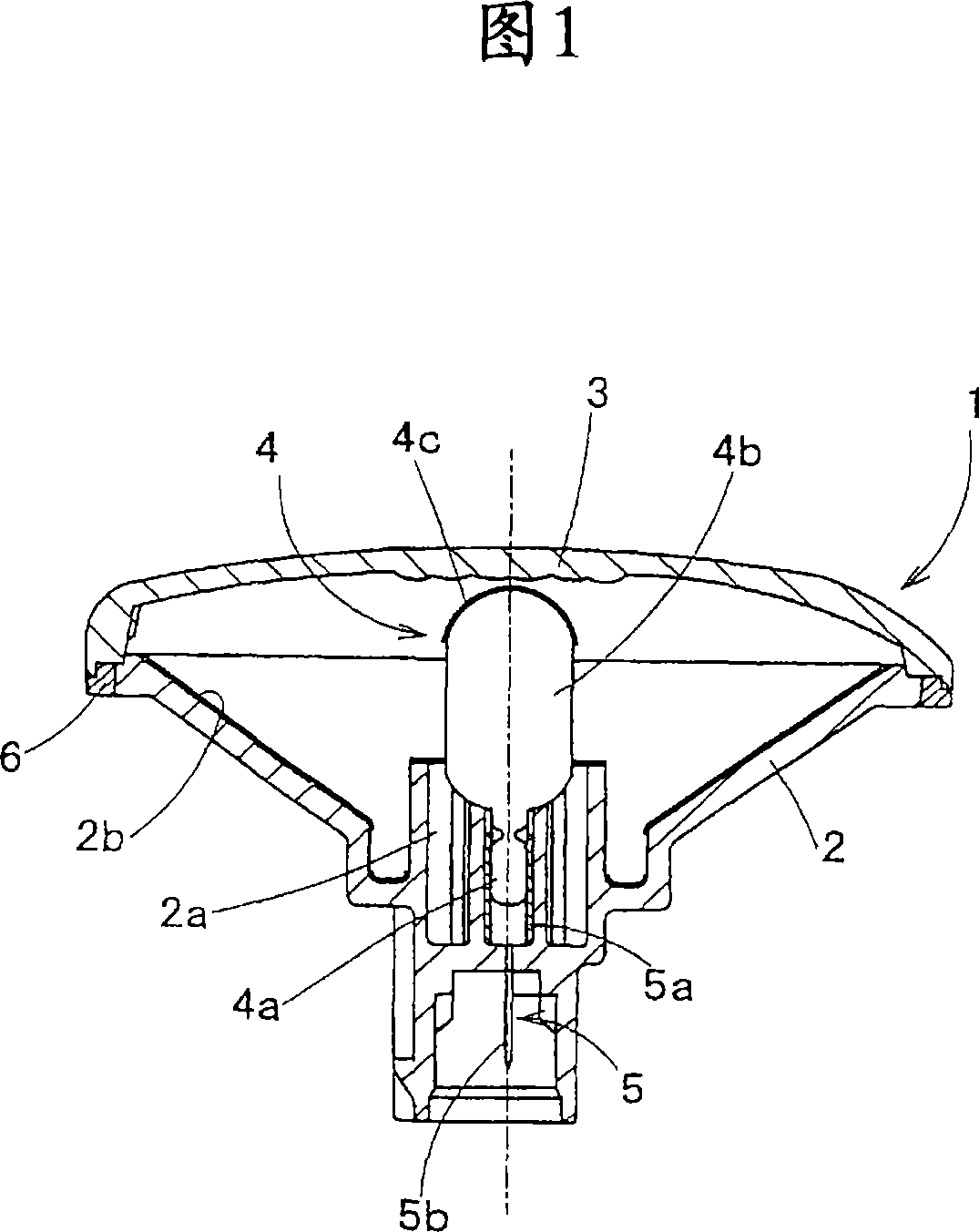

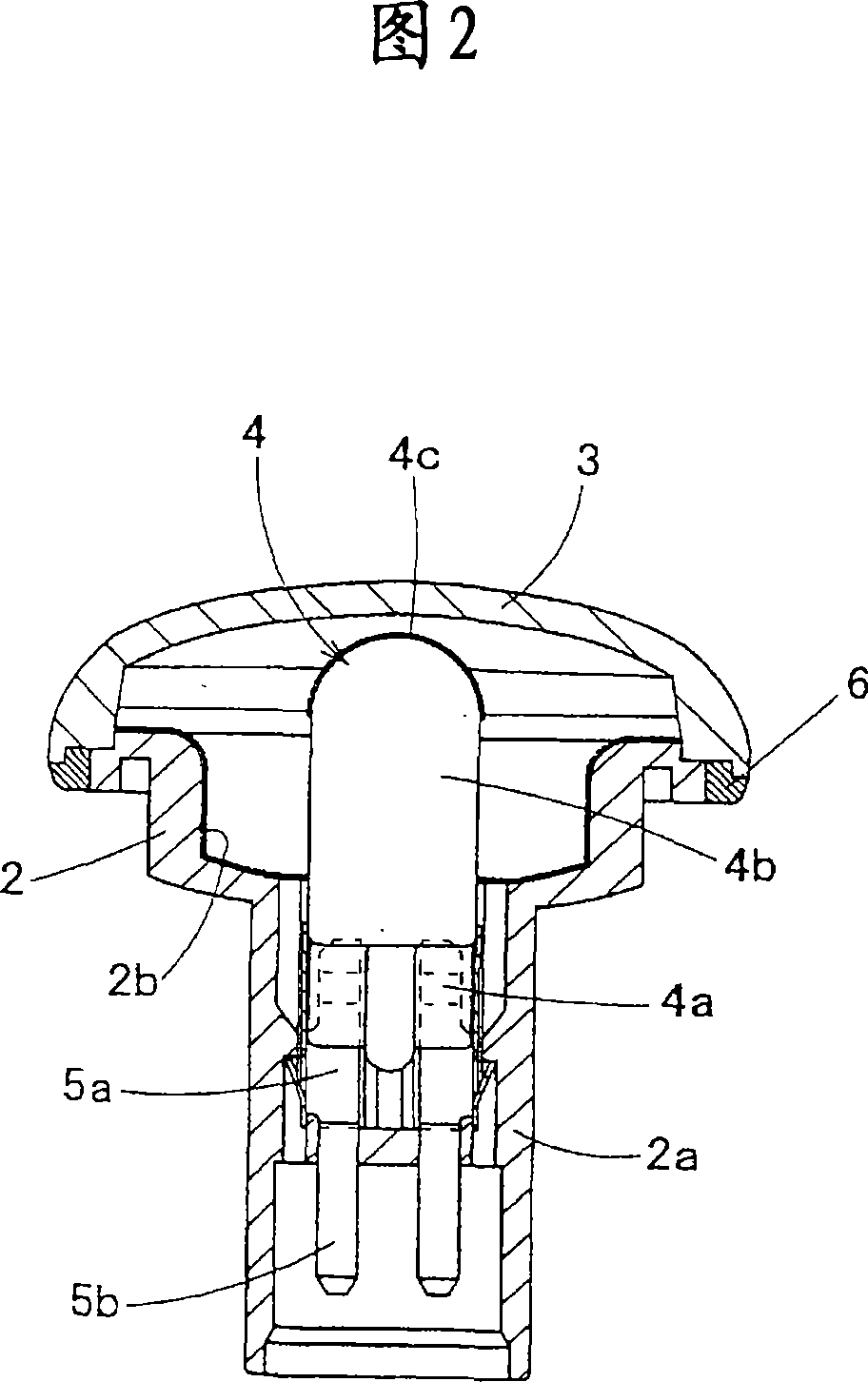

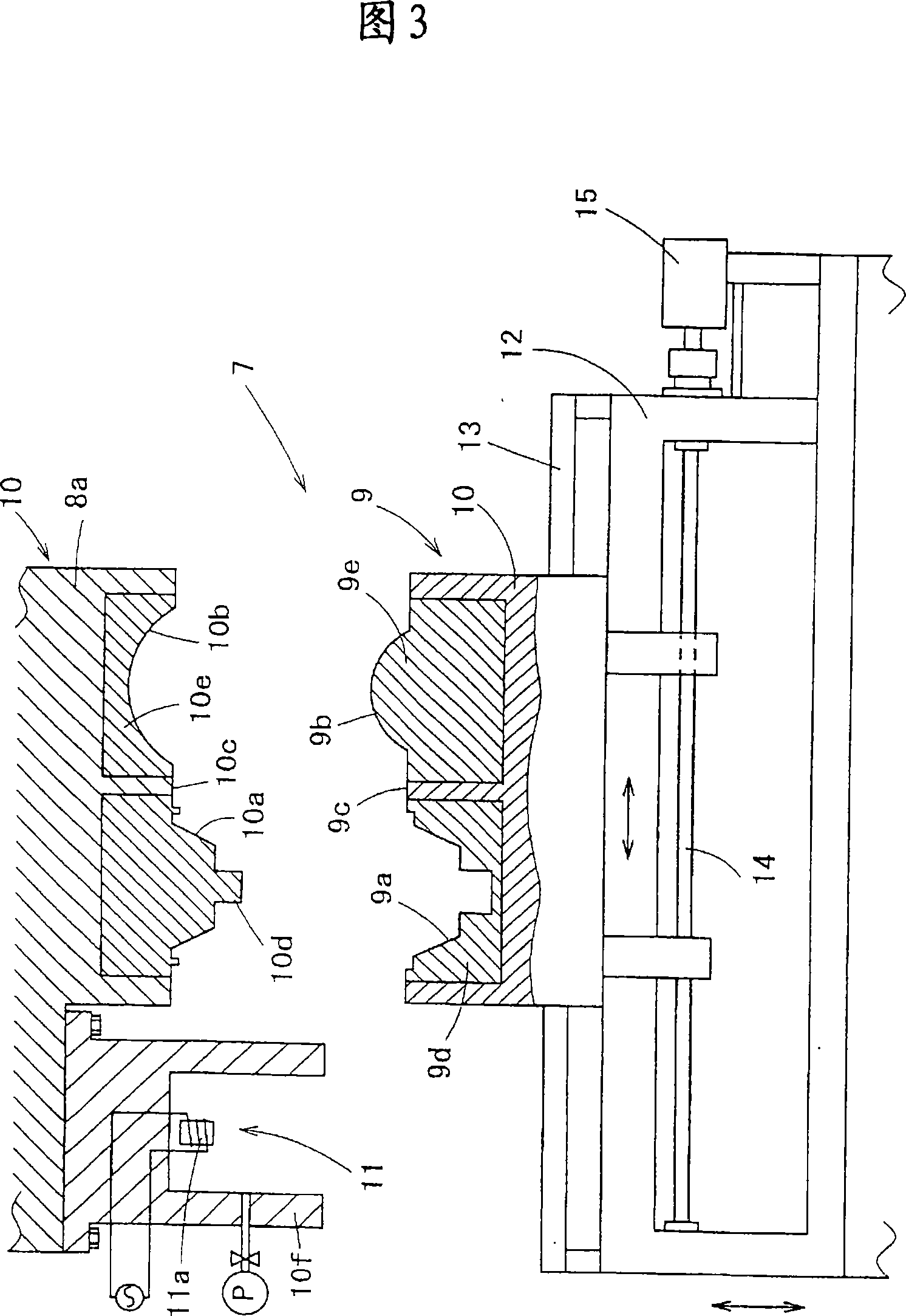

[0038] Embodiments of the present invention will be described below with reference to the drawings. In the figure, 1 is a lamp body for side turning as an example of a film-forming molded body, and this lamp body 1 is a lamp body formed by a mold through a primary injection process by utilizing a resin material 6 injected in a secondary injection process (first injection process). Molded body) 2 and lens part (second molded body) 3 are integrally manufactured, and a component housing part 2a is formed on the lamp main body 2, and the component housing part 2a is used for housing the Bulb (light bulb) 4 and terminal 5. Then, between the primary injection process and the secondary injection process, as will be described later, the lamp body 1 is manufactured through a component mounting process and a film forming process in sequence.

[0039] In this case, the bulb 4 is composed of: a bulb-side connecting portion 4a inserted into the component housing portion 2a and electricall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com