Power hood locking structure for industrial vehicle

A technology for locking structures and industrial vehicles, which is applied in the field of locking structures for power hoods for industrial vehicles, can solve the problems of difficult layout of locking mechanisms and small space, and achieve reliable and compact structures with good locking and opening functions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

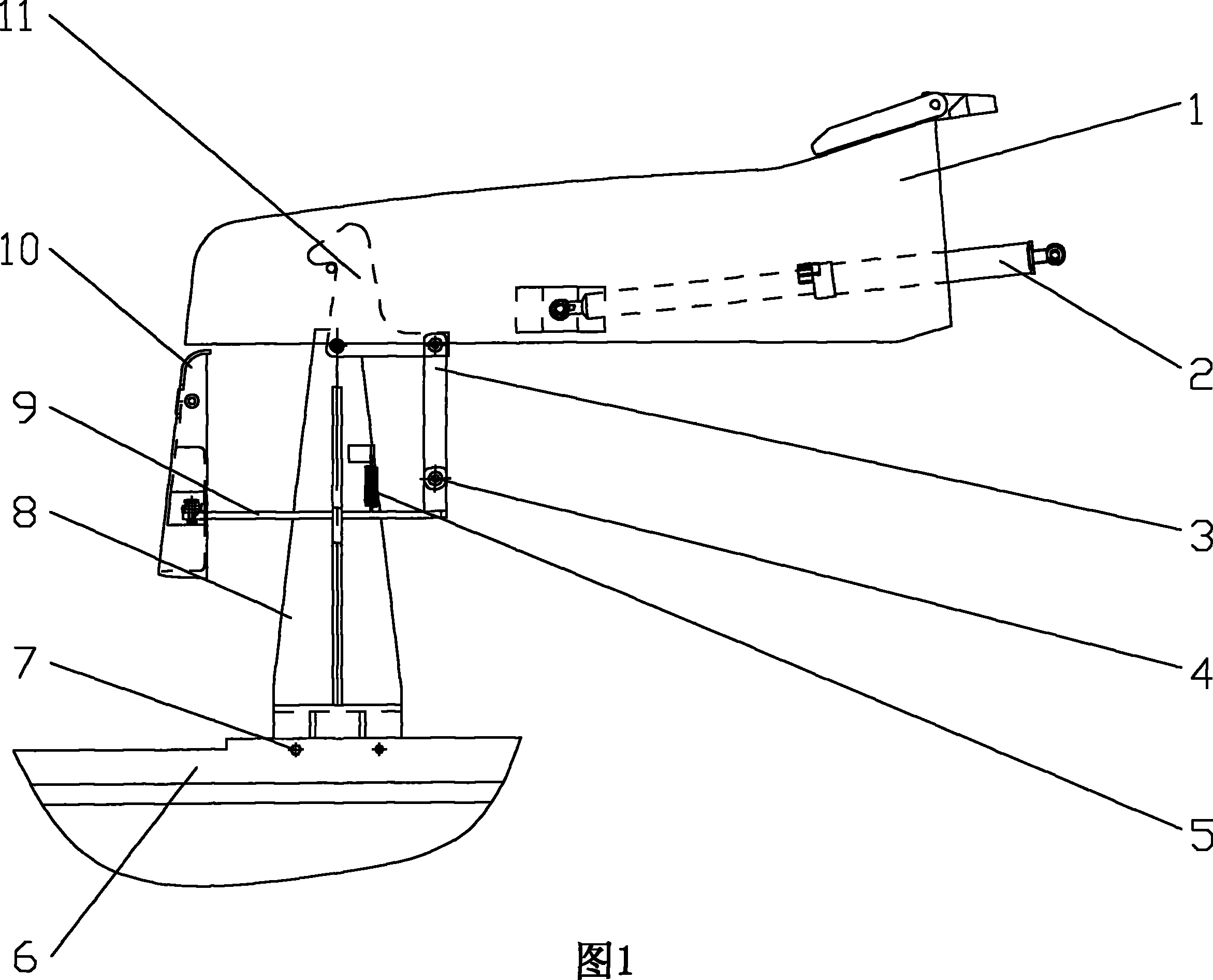

[0013] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

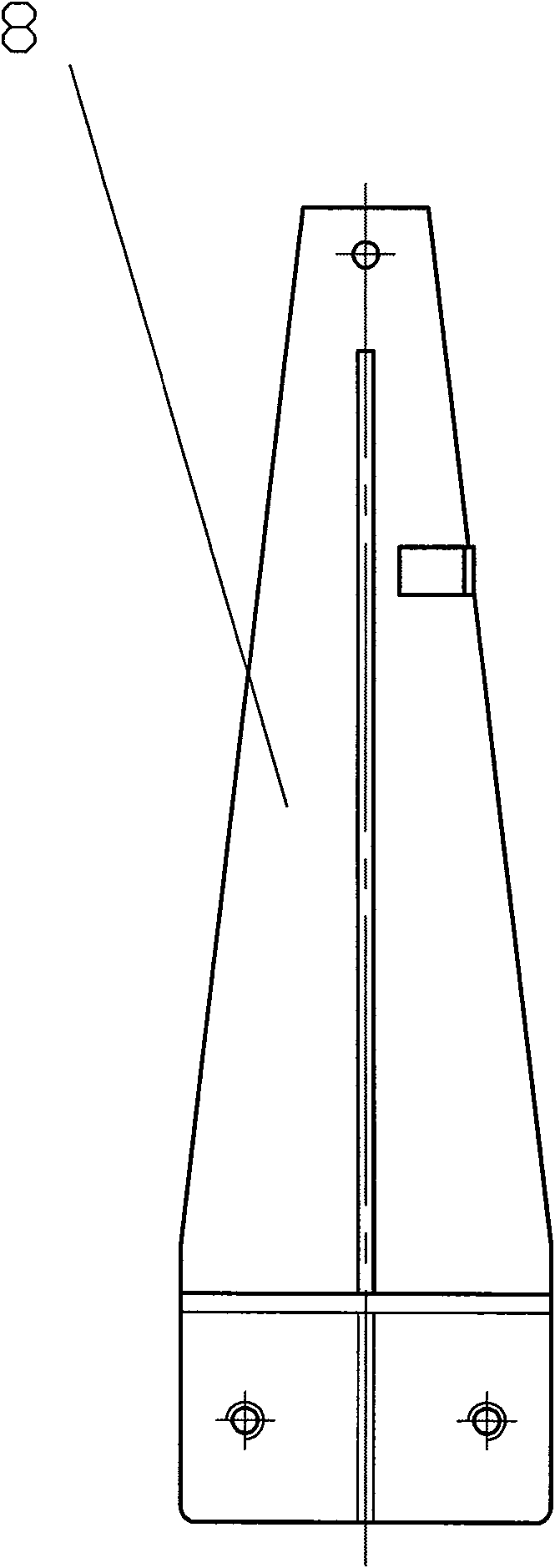

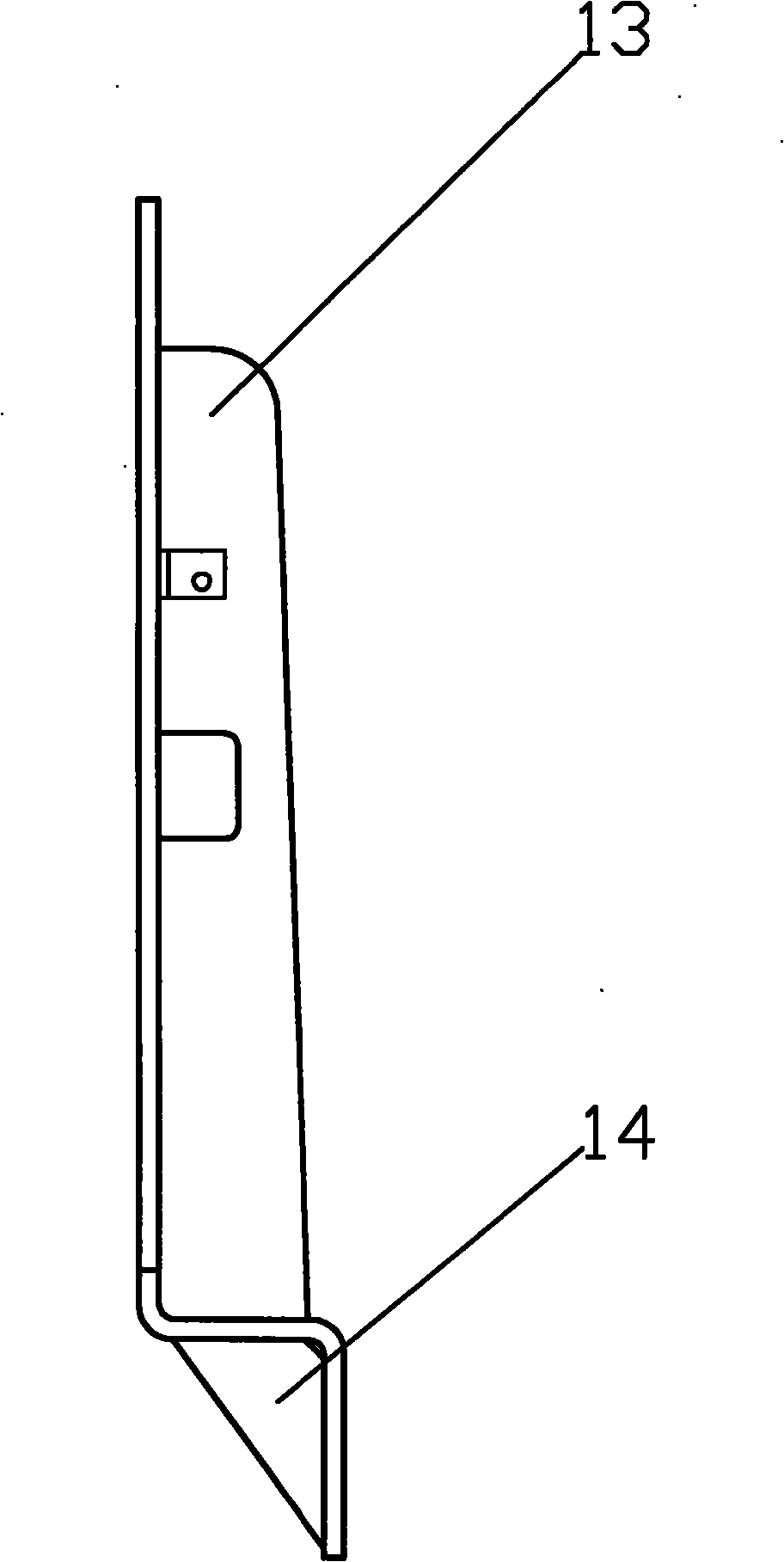

[0014] The present invention mainly consists of a power cover 1, an air spring 2, a pull rod 3, a rivet 4, a return spring 5, a frame side plate 6, a locking bolt 7, a base plate 8, a rotating plate 9, an intermediate support plate 10, and a lock hook 11 , reinforcing ribs 13,14, button 15 and rotating shaft 16 etc. are formed.

[0015] A power cover locking structure for an industrial vehicle of the present invention is arranged between the battery and the side plate of the vehicle frame, occupying little space; the lever mechanism is installed on the middle support plate 10, and the two are arranged at 90°.

[0016] like figure 1 Shown: the air spring 2 is arranged in the power cover 1. When the power cover 1 needs to be locked, the air spring 2 is contracted, and the pin shaft welded in the power cover 1 is in contact with the slope of the locking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com