Method and apparatus for pattern cutting

A technology of ready-made garments and backing boards, applied in the cutting of textile materials, textiles and papermaking, tools for sewing clothes, etc., can solve the problems of negative effects of price factors, tight time, damage, etc., to save time and cost, high quality , to eliminate the effect of movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

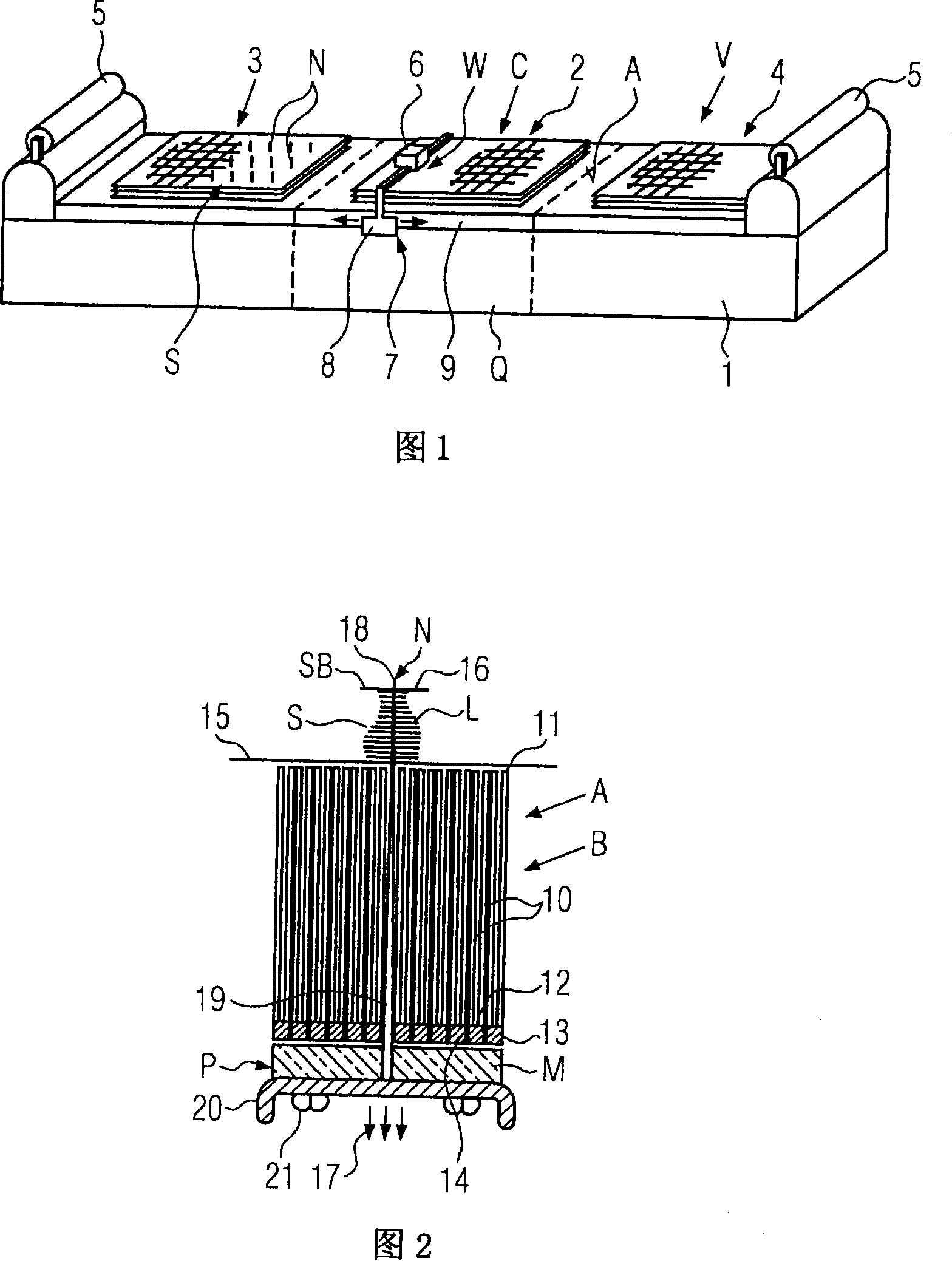

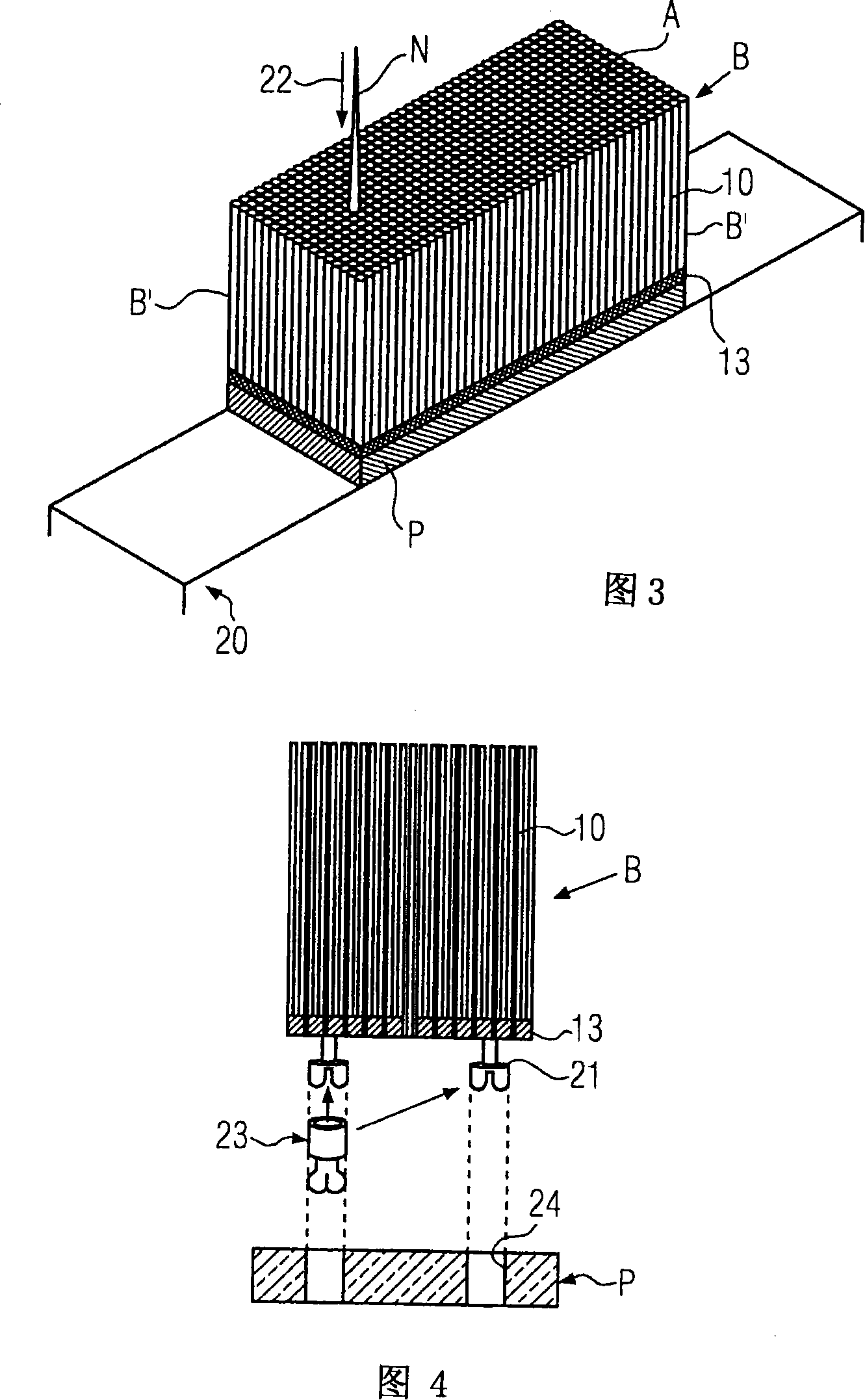

[0029] The apparatus shown in Figure 1 is used in the garment industry, for example in the production of women's outerwear, to form cutouts, in particular cutout laminates of patterned material such as a lattice material, comprising a longitudinally extending frame 1 on which On the upper side, a clipping window is provided in the region 2 of the clipping part C and, for example, placement regions 3 , 4 are provided on both sides of the clipping window. One of the placement areas 4 or 3 is a clearing area. Supports are provided on the frame 1 for supporting cloth or cloth rolls and film rolls 5 . The cutting unit C has a cutting device 6 which moves laterally on the cutting bridge 7 and has a cutting knife W such as a velvet knife. Its cutting bridge 7 moves in the longitudinal direction with a slide 8 on guide rails 9 which are arranged on the longitudinal sides of the frame 1 . Its cutting unit C preferably has a drive control device (not shown) controlled by a computer pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com