Emollients and cosmetic compositions based on special branched hydrocarbons

A technology of composition and mixture, which is applied in the direction of cosmetics, toiletry preparations, cosmetic preparations, etc., and can solve problems that have not been described

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

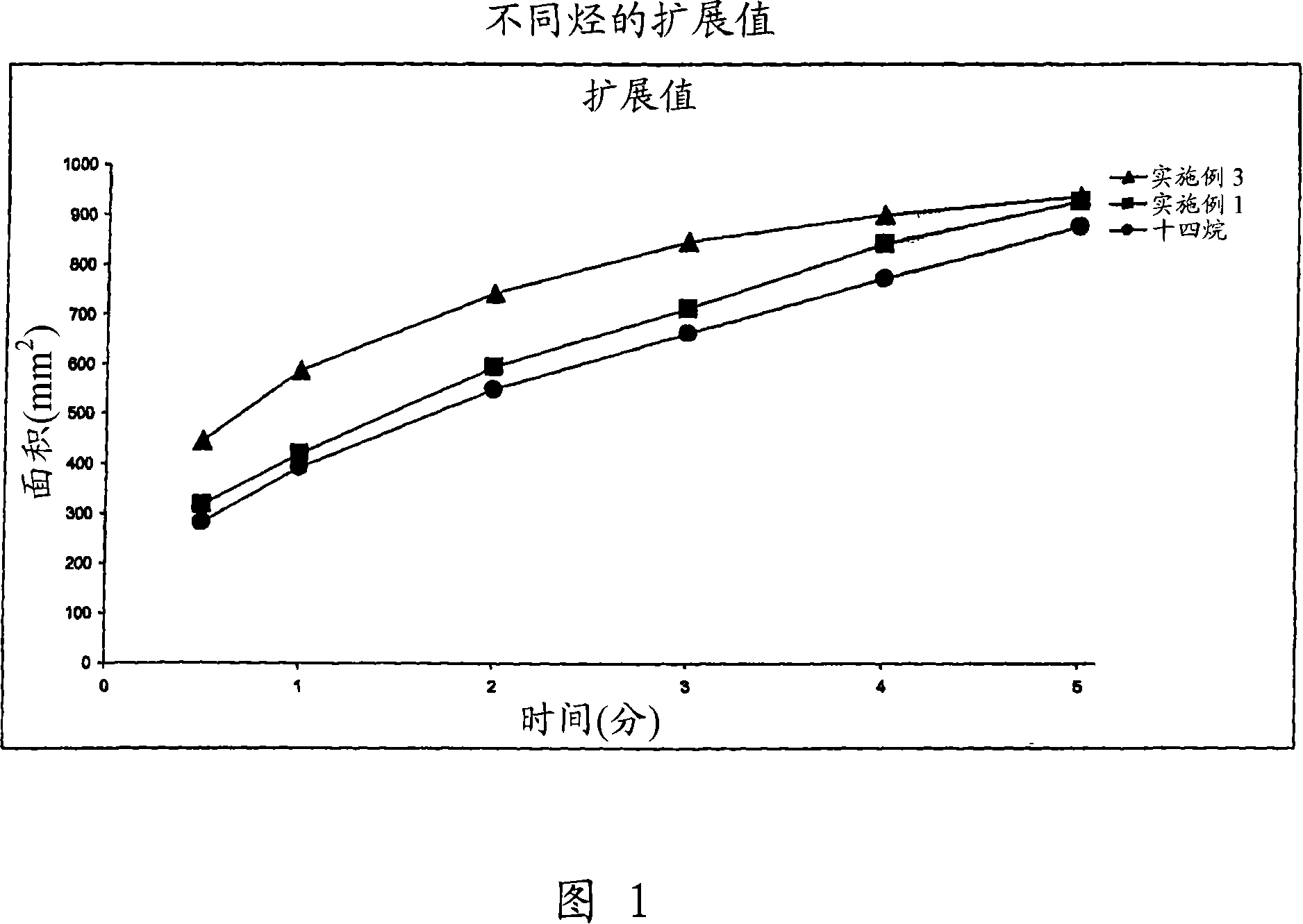

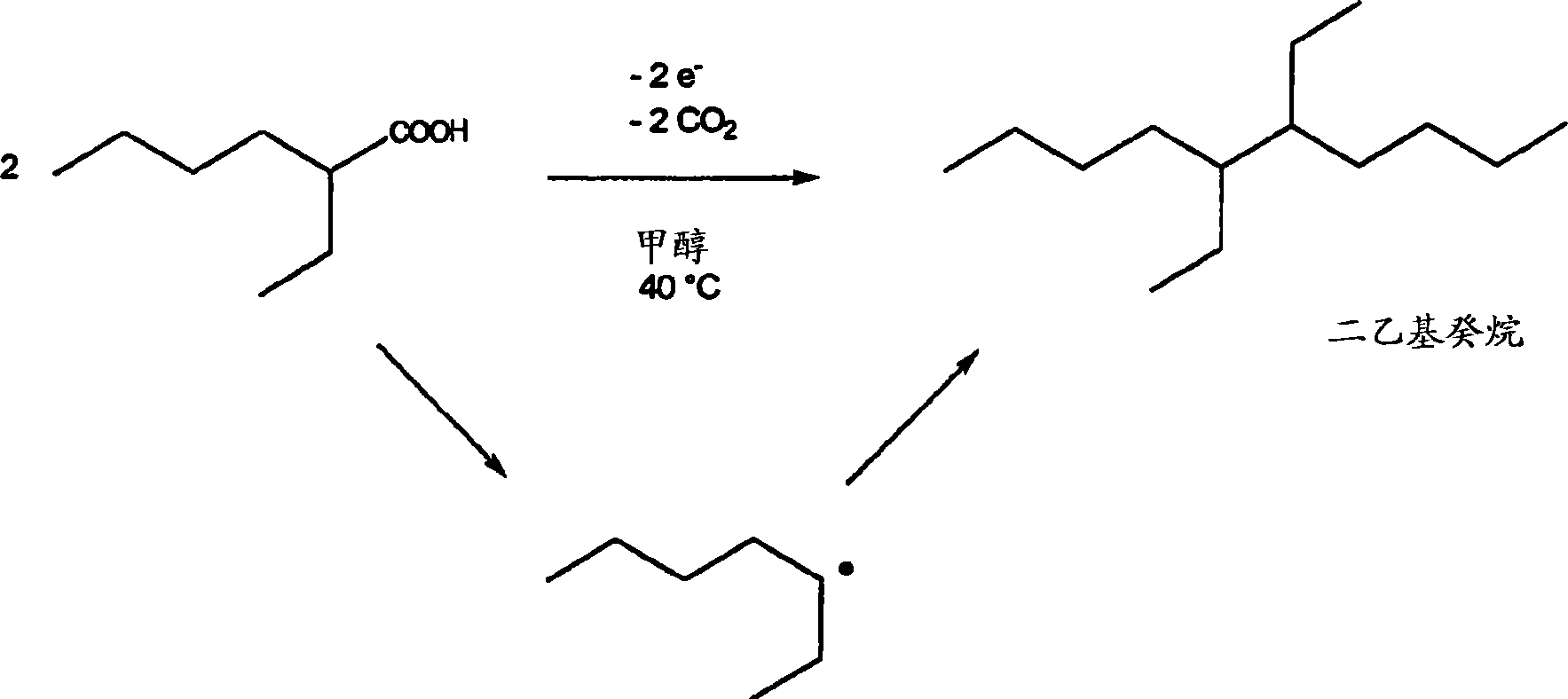

[0049] Electrolysis was carried out in a separate 200ml beaker tank. Each area is 1cm 2 The two platinum electrodes are positioned at a distance of 1-3mm between the electrodes. The electrode is connected to a power supply (3A / 30V). 40 g (0.28 mol) ethylhexanoic acid, 2.5 g sodium methoxide (0.014 mol, 30% solution in methanol) and 4.2 g water were added to the electrolytic cell and filled to 150 ml with methanol. The solution was electrolyzed with stirring at a constant current of 0.5 A, for which a voltage of 26 V was required. The cell was cooled with ice / water so that the temperature was adjusted to 40°C. Electrolysis was stopped after 15 hours. The colorless product precipitates out as the second phase. Yield was 16.0 g. Gas chromatographic analysis of the product indicated >95% diethyldecane (see figure).

[0050]

Embodiment 2

[0052] Electrolysis was carried out in a separate 200ml beaker tank. Each area is 1cm 2 The two platinum electrodes are positioned at a distance of 1-3mm between the electrodes. The electrode is connected to a power supply (3A / 30V). 40 g (0.28 mol) of Cekanoic C8 (Exxon), 2.5 g of sodium methoxide (0.014 mol, 30% solution in methanol) and 4.2 g of water were added to the electrolytic cell and filled to 150 ml with methanol. The solution was electrolyzed with stirring at a constant current of 0.5 A, for which a voltage of 26 V was required. The cell was cooled with ice / water so that the temperature was adjusted to 40°C. Electrolysis was stopped after 15 hours. The colorless product precipitates out as the second phase. Gas chromatographic analysis of the product showed a content of >95% branched C14-hydrocarbons comprising multiple isomers with methyl branches. The methyl branches have the same distribution pattern as the raw material Cekanoic C8. Yield was 17.0 g.

Embodiment 3

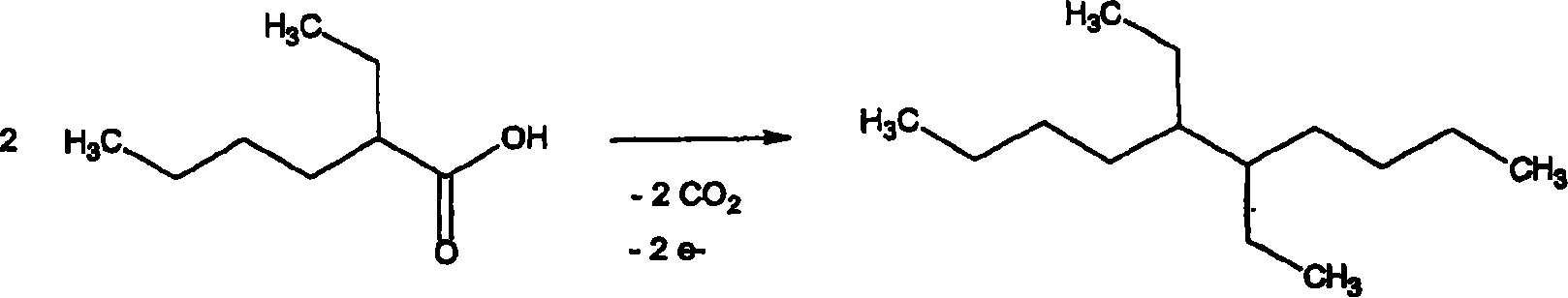

[0054] Electrolysis was carried out in a separate 200ml beaker tank. Each area is 1cm 2 The two platinum electrodes are positioned at a distance of 1-3mm between the electrodes. The electrode is connected to a power supply (3A / 30V). Add 23g (0.16 mol) ethylhexanoic acid, 18.5g (0.16 mol) hexanoic acid, 2.9g sodium methylate (0.016 mol, 30% solution in methanol) and 4.2g water in the electrolytic cell, and fill to 150ml with methanol . The solution was electrolyzed with stirring at a constant current of 0.4 A, for which a voltage of 26 V was required. The cell was cooled with ice / water so that the temperature was adjusted to 40°C. Electrolysis was stopped after 15 hours. The colorless product precipitates out as the second phase. Yield was 18.5 g. Gas chromatographic analysis of the product showed a total content >95% of a mixture of three different hydrocarbons. The three hydrocarbons are decane, ethyl decane and diethyl decane. (see picture)

[0055]

[0056] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com