Image forming apparatus

A technology of imaging equipment and driving force, which is applied in mechanical equipment, equipment of electrical recording technology using charge patterns, electrical recording techniques, etc. The effect of delivering the accuracy guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

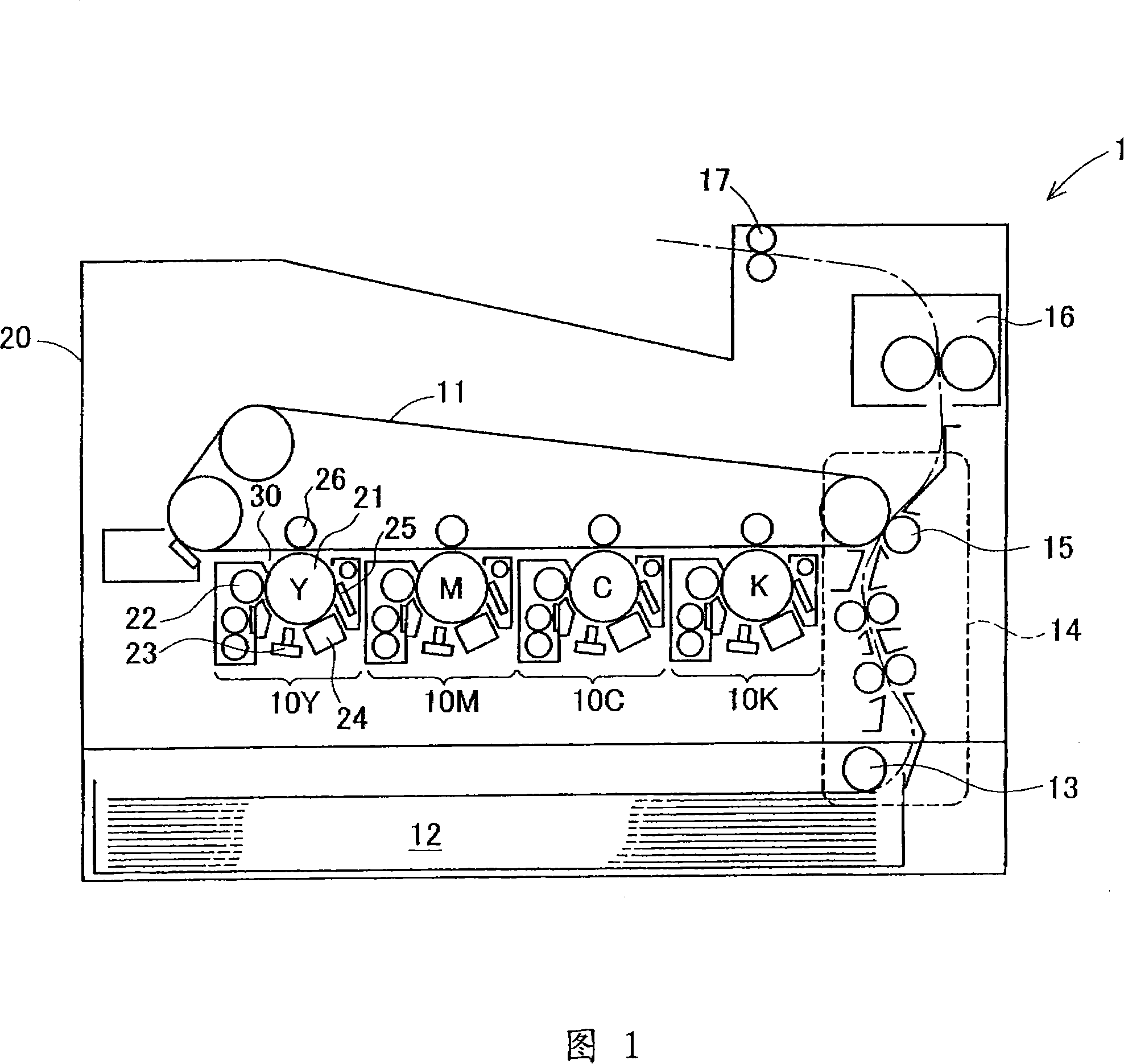

[0081] Hereinafter, a second embodiment of the present invention will be described in detail with reference to the accompanying drawings. This embodiment also relates to a tandem color printer. The overall configuration of this embodiment is the same as that of the first embodiment shown in FIG. 1 .

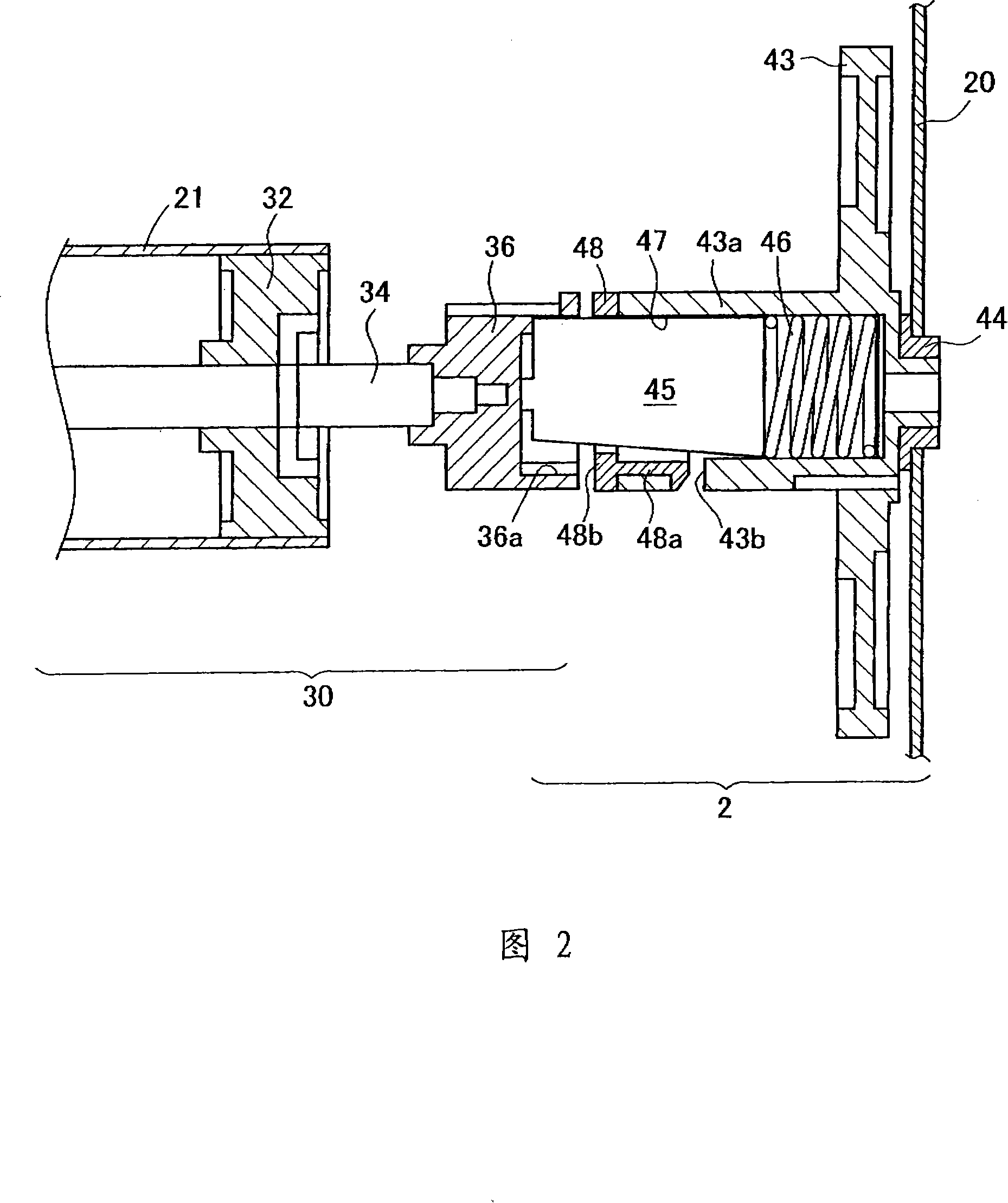

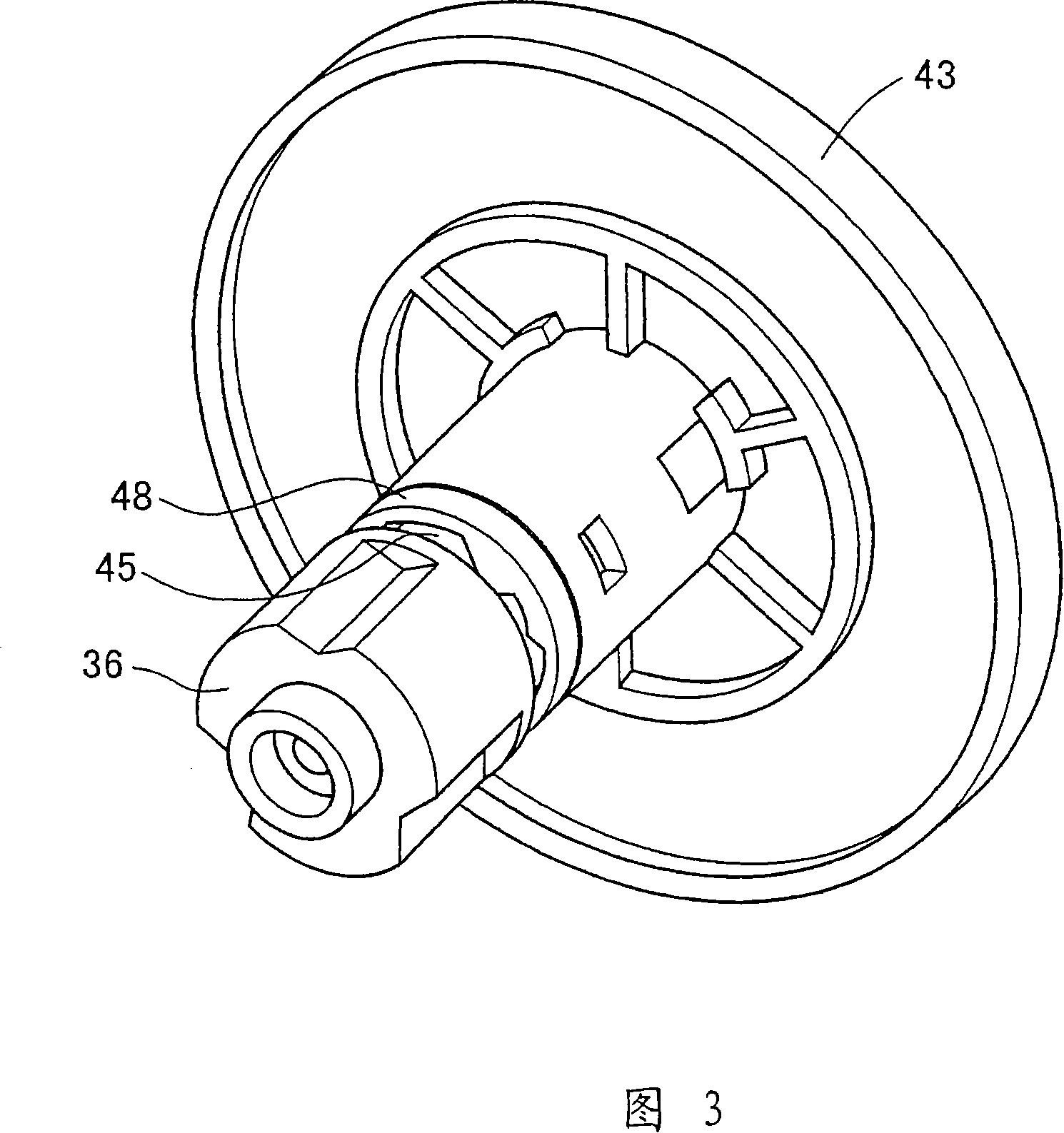

[0082] Next, Figs. 11 and 12 show the outline of the connection part of the main body 2 and the imaging unit 30 of this embodiment. This connecting portion is provided on the deeper side of the color printer in FIG. 1 . Fig. 11 presents a sectional view of the connecting portion. Fig. 12 is an exploded oblique view of the right half of Fig. 11. In the image forming unit 30, as shown on the left side of FIG.

[0083] On the main body 2 side, as shown on the right side of FIG. 11 , a gear 43 is fixed to the housing 20 via a gear shaft support 44 . A link support portion 43a is formed on the gear 43 such that it extends to the left in the figure. The connector supporting porti...

no. 3 example

[0101] Hereinafter, a third embodiment of the present invention will be described in detail with reference to the drawings. This embodiment differs from the first embodiment only in the connection portion between the imaging unit 30 and the main body 2 . Since the entire structure thereof is substantially the same, only differences are described.

[0102] Fig. 17 shows a schematic structure of the connecting portion of this embodiment. In the drawing, the imaging unit 30 is shown on the right. The imaging unit 30 is supported by a housing 31 and includes a photoreceptor 21 , a flange 32 and a shaft support 33 . The flange 32 is fixed to the end of the photoreceptor 21 and rotates integrally with the photoreceptor 21 . The shaft bearing 33 rotatably supports the end of the photoreceptor 21 and is fixed to the casing 31 . A columnar fixing portion 33 a is formed at the left end portion of the shaft support 33 in the figure.

[0103] In the main body 2, as shown on the left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com