Photographic emulsion supplying device

A supply device and photosensitive glue technology, which is applied in the manufacture of discharge tubes/lamps, electrical components, cold cathodes, etc., can solve problems such as difficult to eliminate, white spots, and glue-coated white spots, so as to eliminate primary bubbles and meet continuous production , the effect of constant flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

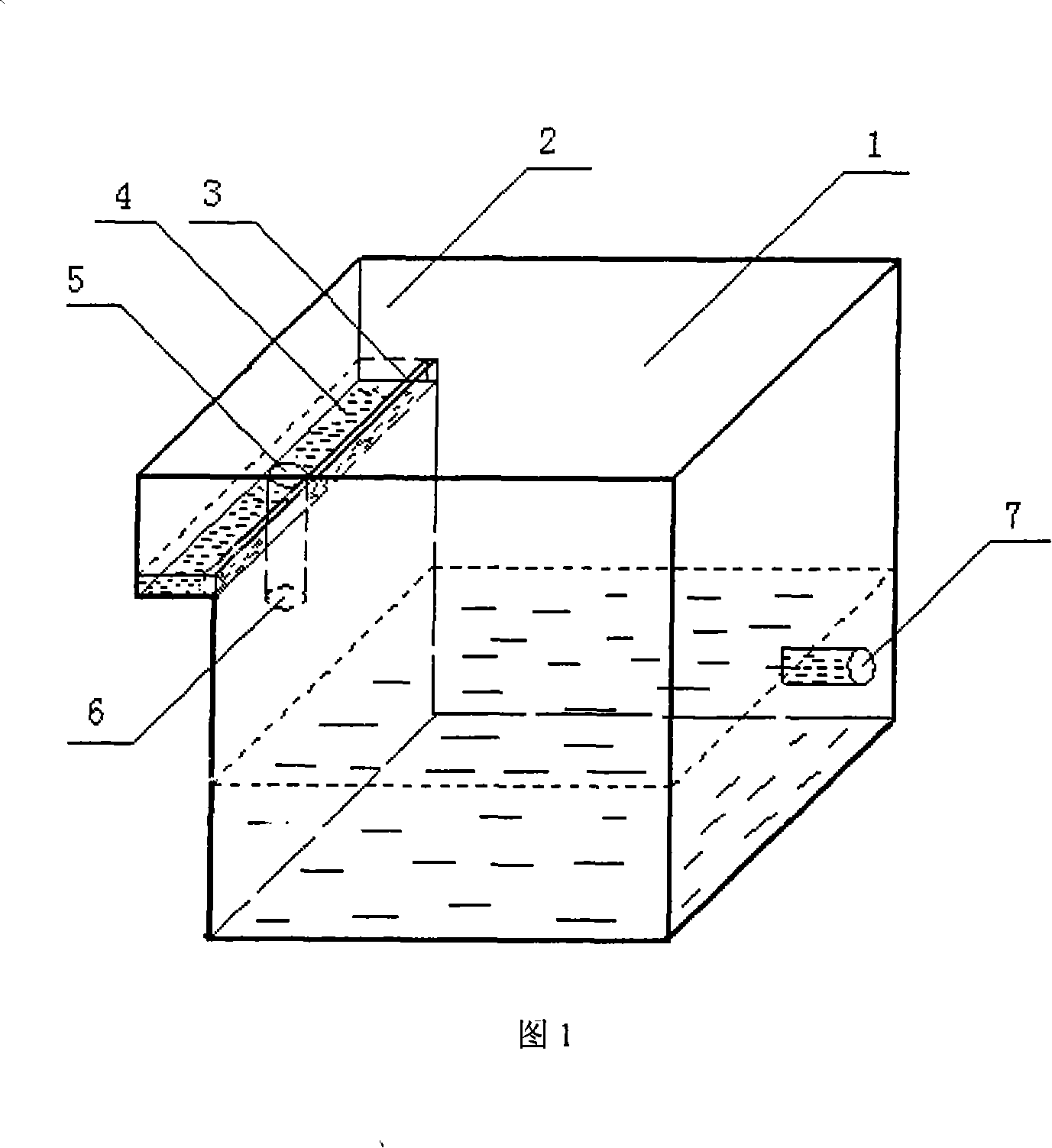

[0010] As shown in Figure 1, a supply device for photosensitive glue liquid includes a photosensitive glue liquid inlet 6 connected with a quantitative pump hose, a photosensitive glue liquid outlet 7 connected with a coating tank delivery hose, and a photosensitive glue liquid The outlet 7 is arranged on the lower part of one side of the rectangular box body 1, which is connected to the rectangular box body 1 through a horizontal pipe, and a platform protruding 2 is provided on the upper part of the other symmetrical side of the rectangular box body 1, and a partition plate 3 is provided to connect the platform The protrusion 2 forms an overflow tank 4, and the inlet 6 of the photosensitive glue is communicated with the overflow tank 4 through an overflow tube 5 perpendicular to the bottom of the overflow tank 4, and the height of the upper en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com