Granular rice protein and preparing method and application of the same

A rice protein and granular technology, applied in the field of rice protein, can solve the problems of unfavorable digestion and absorption, large water resources, cumbersome production and operation process, etc., and achieve less reaction materials and equipment, lower production costs, and good sensory effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

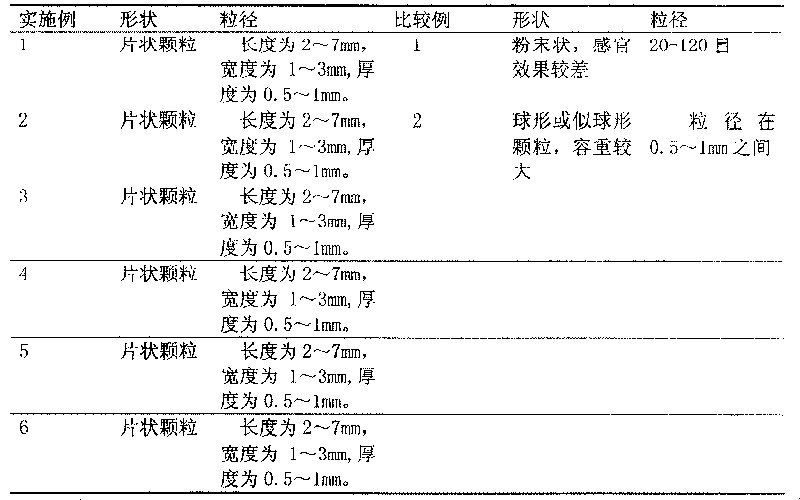

Examples

Embodiment 1

[0028] Select 600kg of high-quality rice, add 3000kg of water to the rice, and add 1.2×10 high-temperature α-amylase to the above-mentioned rice with water 7 Stir and adjust the pH to 5.0 after the unit, heat the temperature to 90°C for enzymolysis, and the time for enzymolysis is 200 minutes. After the enzymolysis is completed, the rice protein and enzymolysis solution are pumped into the filter press with a centrifugal pump for pressure filtration. Through the action of pressure and filter cloth, the rice protein and enzymolysis solution can be separated from solid to liquid. The conditions of pressure filtration are relatively simple, as long as the pressure of the centrifugal pump reaches above 0.15mpa. Granular rice protein can be obtained after drying at 80°C and a vacuum of -0.05mpa for 6 hours; the enzymatic hydrolysis solution separated by pressure filtration can be further processed to obtain by-products such as glucose, monosodium glutamate, and citric acid. From the...

Embodiment 2

[0030]Select 600kg of high-quality rice, add 1200kg of water to the rice, and add 1.2×10 high-temperature α-amylase to the above-mentioned rice with water 7 Stir and adjust the pH to 6.0 after the unit, heat the temperature to 110°C for enzymolysis, and the time for enzymolysis is 100 minutes; after the enzymolysis, use a centrifugal pump (or use a high-level self-flow) to introduce the rice protein and enzymolysis solution into a vacuum suction The filter machine, through the action of vacuum and filter cloth, sucks out the liquid phase in the enzymatic hydrolysis solution to realize solid-liquid separation; the conditions for suction filtration separation are relatively simple, and the vacuum degree of suction filtration can reach above -0.07mpa; through suction filtration separation Finally, the granular rice protein filter cake and enzymolysis solution are obtained, and the granular rice protein filter cake obtained above is dried for 4 hours at a temperature of 90°C and a ...

Embodiment 3

[0032] Select 600kg of high-quality rice, add 1500kg of water to the rice, and add high-temperature α-amylase 2.4×10 to the above-mentioned rice with water 7 Stir after the unit and adjust the pH to 7.0, and heat the temperature to 100° C. for enzymolysis, wherein the enzymolysis time is 60 minutes. After the end of enzymolysis, the rice protein and enzymolysis solution are introduced into the centrifuge with a centrifugal pump (or using high-level self-flow), and the solid-liquid separation is realized through the centrifugal action of the material in the high-speed rotating centrifuge and the function of the centrifuge screen. Condition: The separation factor of the centrifuge is >500. Granular rice protein filter cake and enzymatic hydrolysis solution are obtained after centrifugation, and the granular rice protein filter cake obtained above is dried for 2 hours at a temperature of 95°C and a vacuum of -0.03mpa to obtain a granular Rice protein; by-products such as glucose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com