Back penetration measuring method for film base binding performance

A technology that combines performance and measurement methods, applied in the field of measurement, can solve the problems of complex prefabrication of the components to be tested, and the limitation of the substrate system by silicon materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

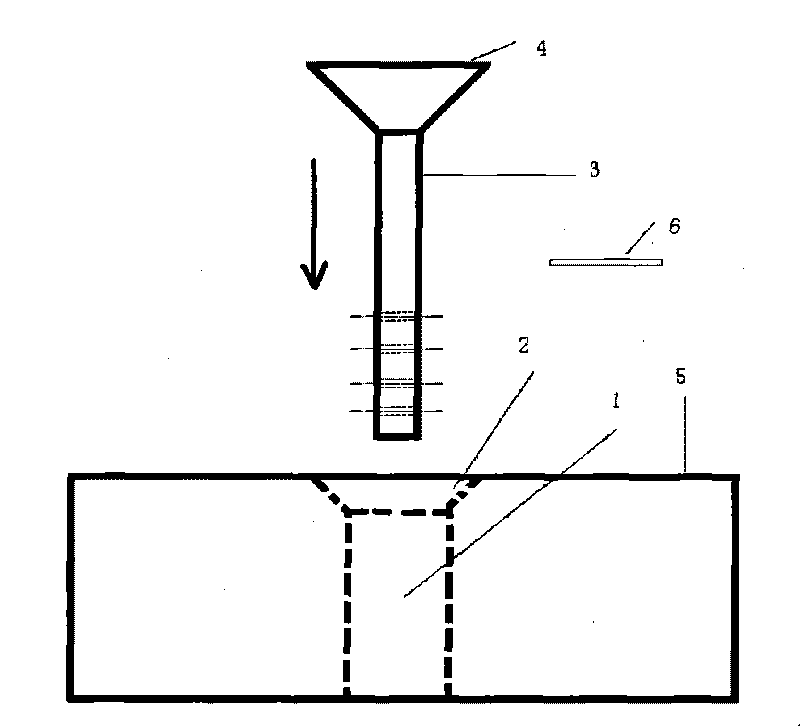

[0026] Step 1: Machining a round through hole 1 with a radius of 1.5mm on a substrate with a size of 40mm×20mm×5mm, and machining a figure 1 Chamfer 2 of 45° shown.

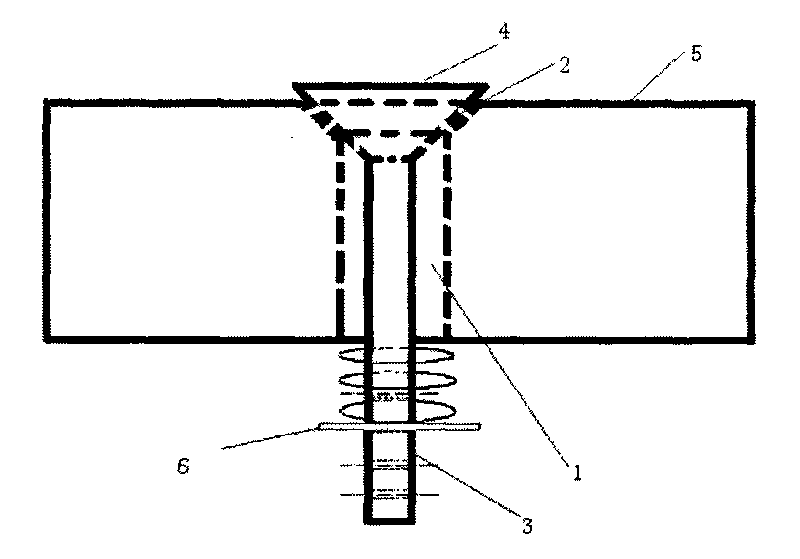

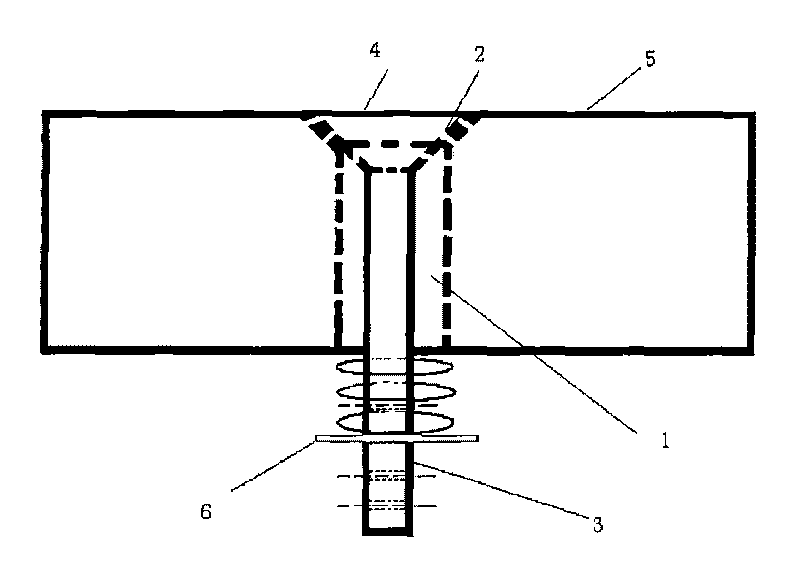

[0027] The second step: process a matching ejector pin 3 . Such as figure 2 As shown, in the substrate system after assembly, the top end surface 4 of the ejector pin is 0.75mm higher than the substrate coating surface 5, as image 3 Grind the coated surface as shown. Ensure that the coating surface is flat and smooth.

[0028] Step 3: Put a spring with a radius 0.5-1mm larger than the radius of the base hole at the lower end of the ejector rod and with a higher rigidity, such as figure 2 As shown, a hole is drilled in the rod part of the ejector rod, a latch 6 is inserted, and the spring is compressed between the latch and the base, thus making the ejector rod and the base in a tight contact state. This is because when the film-based system adopted in the present invention is polished on the coating surfa...

Embodiment 2

[0034] Step 1: Machining a circular through hole 1 with a radius of 1.5mm on the base of the component to be tested, and machining a figure 1 Chamfer 2 of 35° shown.

[0035] The second step: process a matching ejector pin 3 . Such as figure 2 As shown, in the substrate system after assembly, the top end surface 4 of the ejector rod is 0.5 mm higher than the coating surface 5 of the substrate.

[0036] Other steps are with embodiment 1.

[0037] Step 5: Load in the form of dynamic load at the lower end of the ejector rod. Under a certain number of dynamic loads, the membrane will deflect to a certain extent. The oil immersion method can be used to measure the The measured area radius of the detached base area can be used as the fatigue crack growth length of the membrane, and thus the fatigue crack growth length of the membrane under different loading cycles can be obtained, which characterizes the fatigue performance of the membrane.

[0038] In this embodiment, the pref...

Embodiment 3

[0040] Step 1: Machining a circular through hole 1 with a radius of 1.5mm on the base of the component to be tested, and machining a figure 1 Chamfer 2 of 85° shown.

[0041] The second step: process a matching ejector pin 3 . Such as figure 2 As shown, in the substrate system after assembly, the top end surface 4 of the ejector pin is 1 mm higher than the coating surface 5 of the substrate.

[0042] Other steps are with embodiment 1.

[0043]Step 5: Load in the form of dynamic load at the lower end of the ejector rod. Under a certain number of dynamic loads, the membrane will deflect to a certain extent. Under the acoustic emission microscope, the corresponding measured values for different cyclic loading times can be obtained. The measured area radius of the detached base area can be used as the fatigue crack growth length of the membrane, and thus the fatigue crack growth length of the membrane under different loading cycles can be obtained, which characterizes the fa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com