LED lighting lamp

A technology of LED lighting and LED light source, which is applied in the field of lighting, can solve the problems of troublesome replacement of new light sources, time-consuming and laborious, poor heat dissipation effect of street lamps, etc., and achieve the effects of easy heat dissipation, saving investment, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

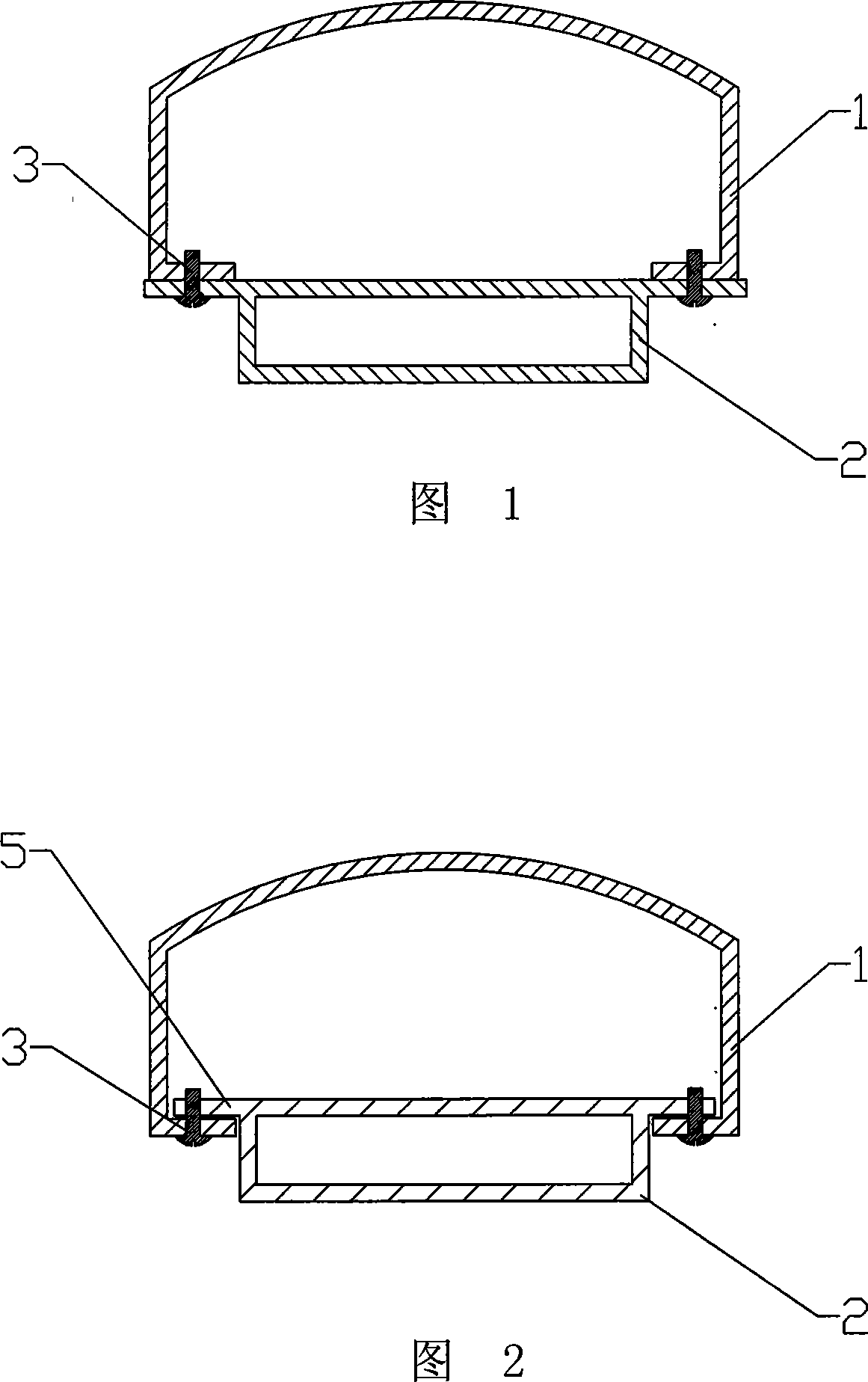

[0028] Embodiment 1, as shown in FIG. 1 , an LED lighting lamp includes a lamp housing body 1 and an LED light source body 2. The LED light source body 2 is arranged at the lower part of the lamp housing body 1. The connection between the LED light source body 2 and the lamp housing body 1 is on the outer surface of the lamp housing body 1. The assembly process of the LED lighting lamp is as follows: first assemble the LED light source body 2, and then put the LED light source body The backlight surface of the body 2 is aligned with the light outlet of the lamp housing body 1, and fixed with bolts 3. When fixing, the backlight surface of the light source body is provided with a connecting piece, and the connecting piece has a part connected to the light source body and an extension for bolt connection. Part, the structure and form of the connector can adopt a structural form that is convenient for connection according to the structure of the lamp housing body, such as a bent st...

Embodiment 2

[0029] Embodiment 2, as shown in FIG. 2 , an LED lighting lamp includes a lamp housing body 1 and an LED light source body 2. Both sides of the LED light source body 2 have extensions for connecting with the inner bending part of the lamp housing body 1. Part 5, the LED light source body 2 is arranged outside the lamp housing body 1, the LED light source body 2 and the lamp housing body 1 are connected by bolts 3, and the connection between the light source body 2 and the lamp housing body 1 is in the lamp housing body 1, the assembly process of the LED lighting lamp is as follows: first assemble the LED light source body 2, then align the backlight surface of the LED light source body 2 with the light outlet of the lamp housing 1, and the extension part 5 of the LED light source body 2 and the lamp housing The inner bent parts of the body 1 are aligned and fixed with bolts 3. This structure is very simple and easy to maintain.

Embodiment 3

[0030] Embodiment 3, as shown in FIG. 3 , an LED lighting lamp includes a lamp housing body 1 and an LED light source body 2 , the LED light source body 2 is arranged outside the lamp housing body 1 , and between the light source body 2 and the lamp housing body 2 The parts connected to each other are on the outer surface of the lamp housing body 1 , the LED light source body 2 and the lamp housing body 1 are connected to each other through glue bonding, and an adhesive bonding layer 4 is formed between them.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com