Tea-water separating type paper teacup forming combined machine

A tea water separation and forming machine technology, which is applied in the direction of cardboard winding items, packaging item types, solid materials, etc., can solve the problems of single function of the forming machine and the inability to produce double-layer paper tea cups, etc., to achieve high production efficiency, cup wall Hard, structurally advanced effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

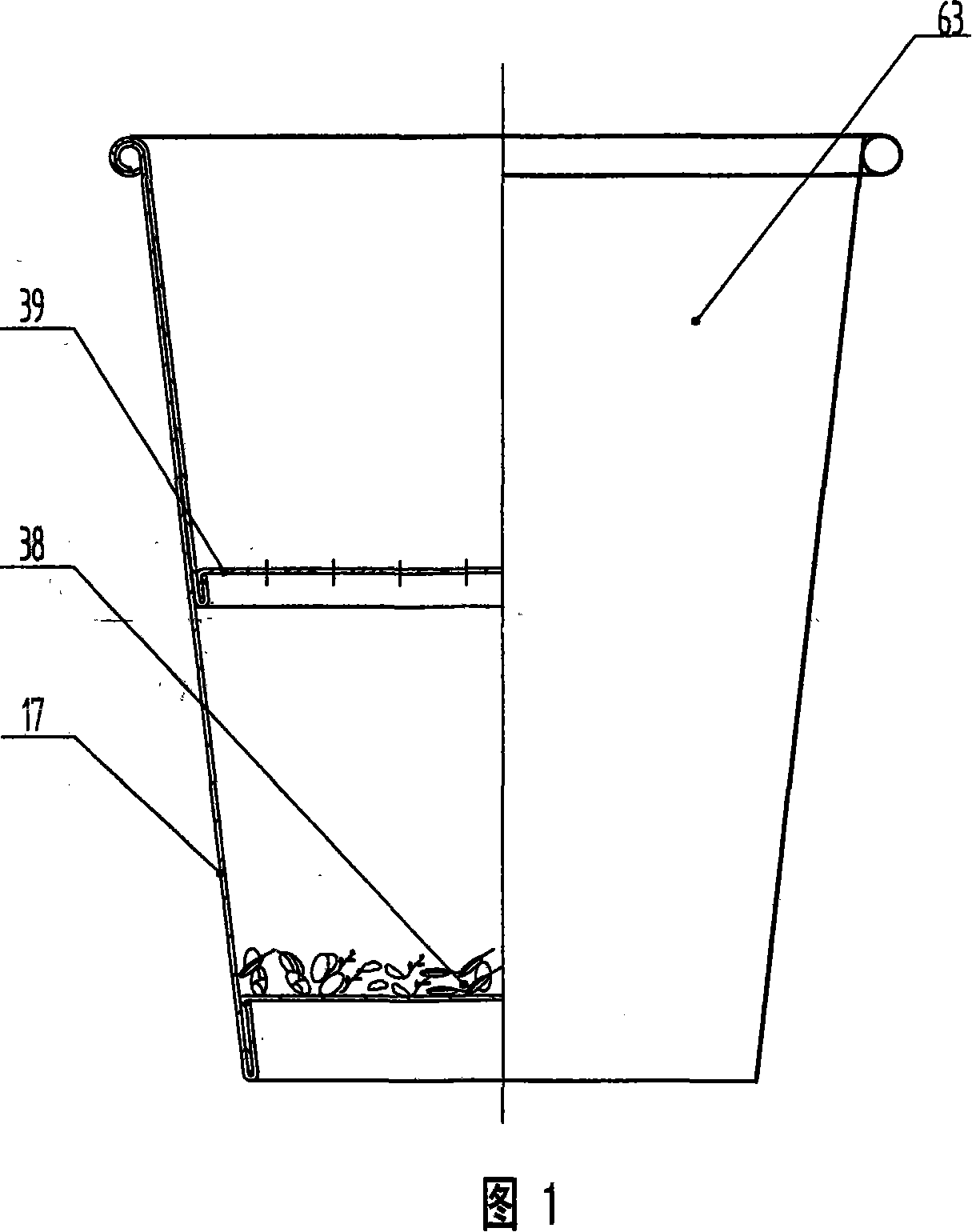

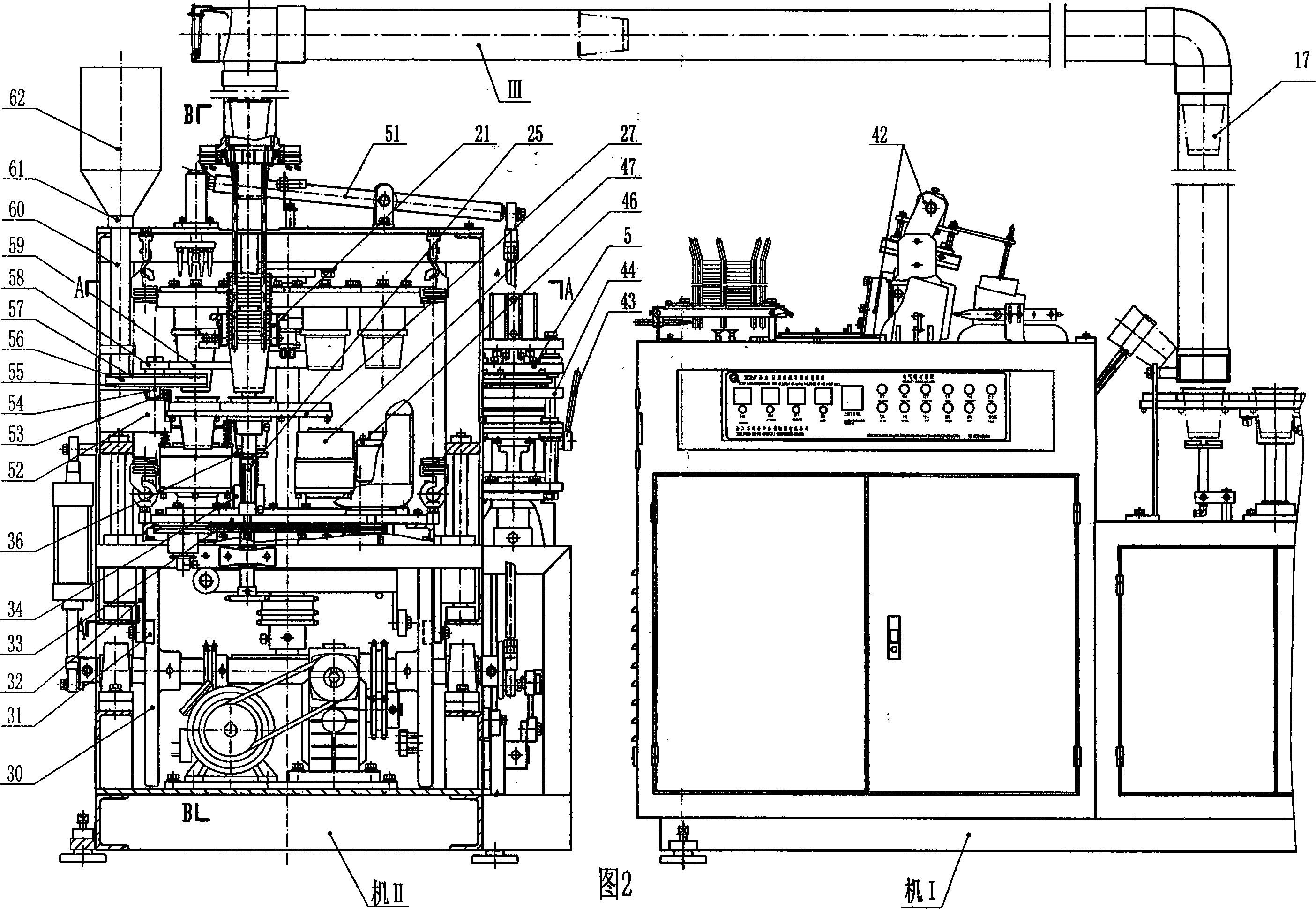

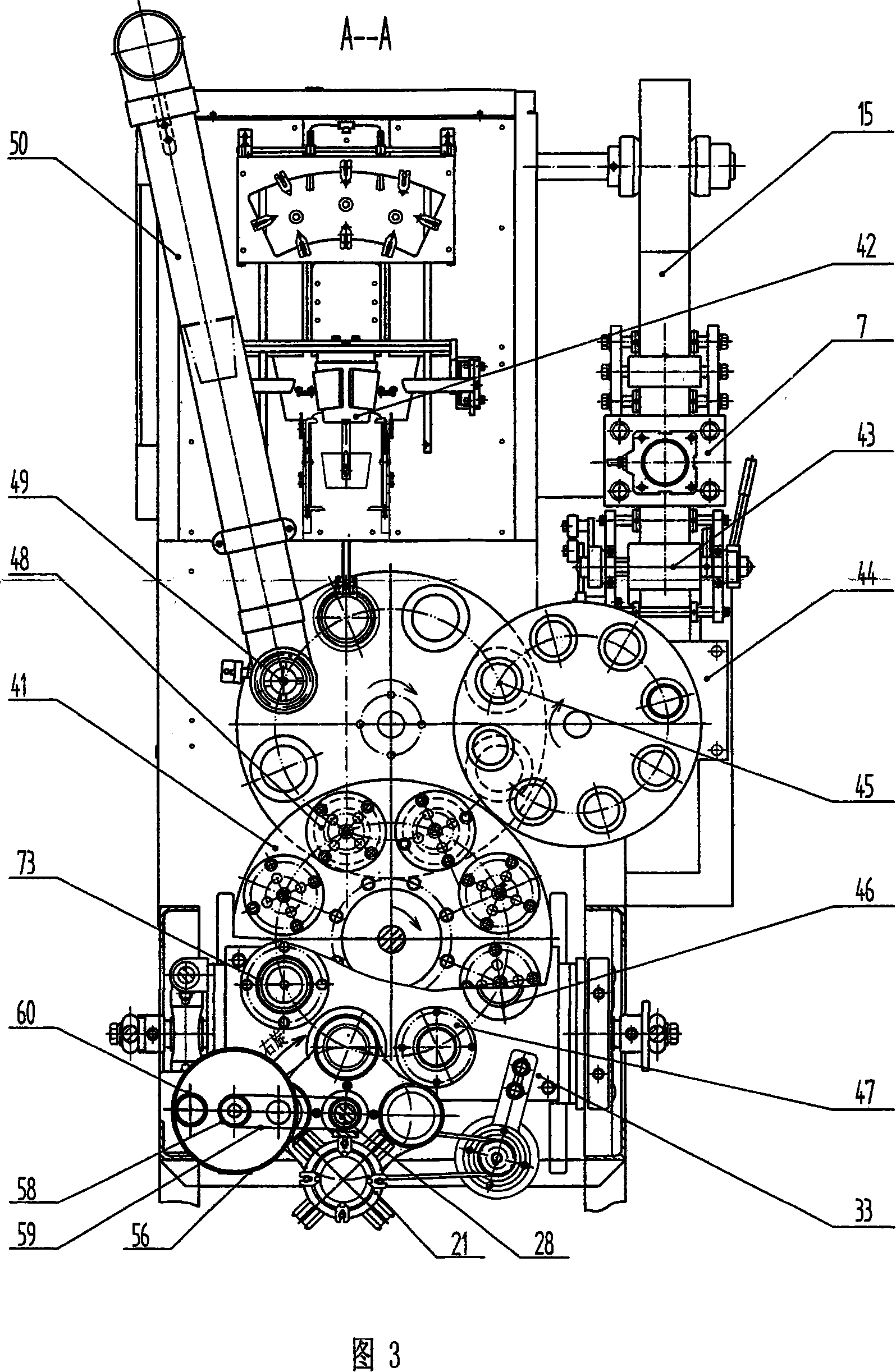

[0022] As shown in the figure, this tea-water separation type paper tea cup forming line includes a single-layer lining cup forming machine II and a single-layer outer cup forming machine I. The inner cup and outer cup forming machines both include a cup body sealing mechanism 42, a cup The bottom cutting mechanism 44, the cup body and body bottom combination mechanism 45, the cup bottom heat curling mechanism 46, the cup bottom rolling sealing mechanism 47, and the cup discharge mechanism 48 are driven by the intermittent box 29 through the transmission mechanism to form the single-layer outer cup. The machine I is provided with a crimping mechanism for the mouth of the cup, and there is also a pipeline delivery outer cup mechanism III between the inner cup forming machine II and the outer cup forming machine I. This mechanism adopts the technical feature of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com