Wheel assembly with in-wheel motor

A technology of wheel components and in-wheel motors, applied in electric components, electric vehicles, vehicle parts, etc., can solve disadvantages and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In the following description and drawings, the invention is described in more detail in exemplary embodiments.

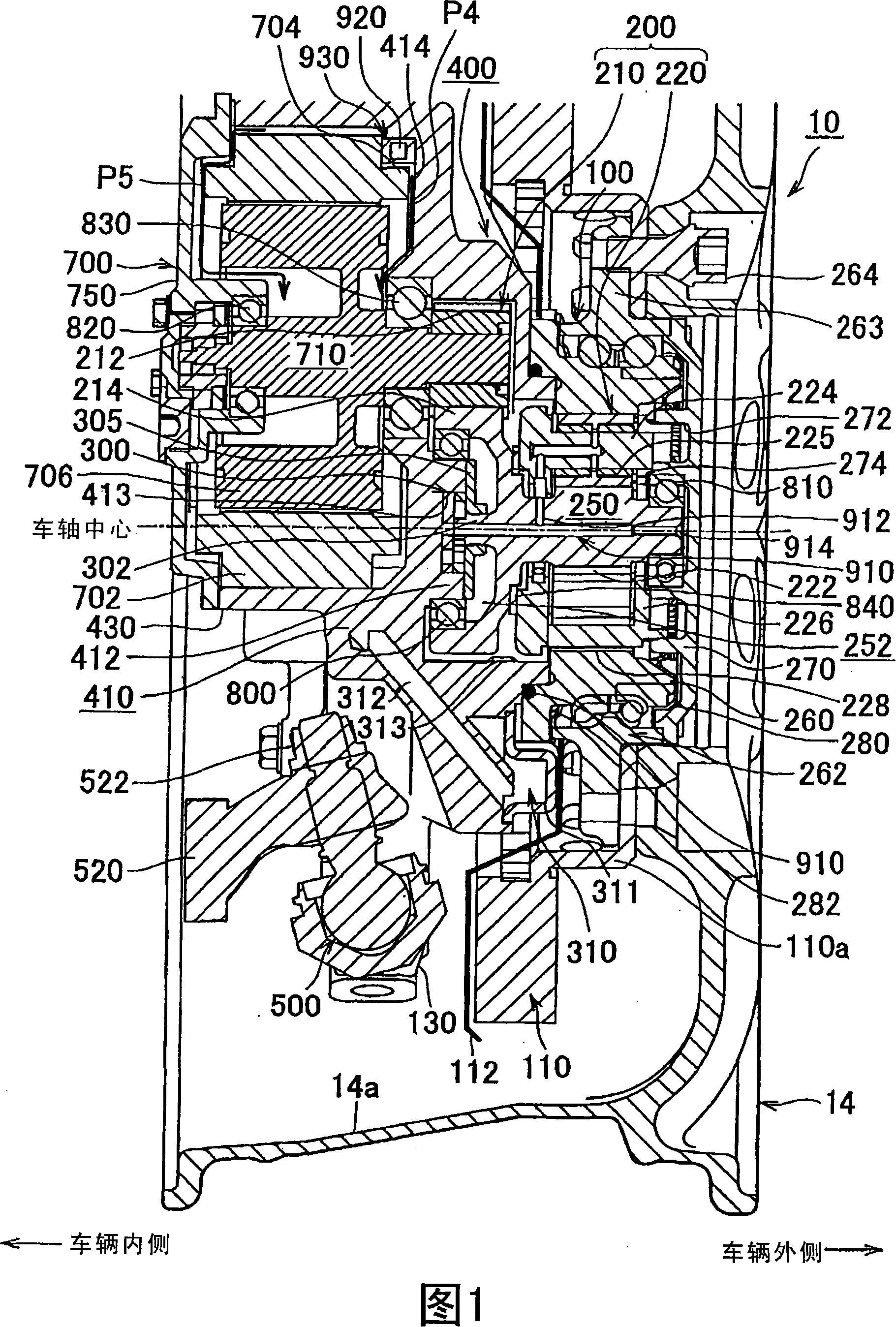

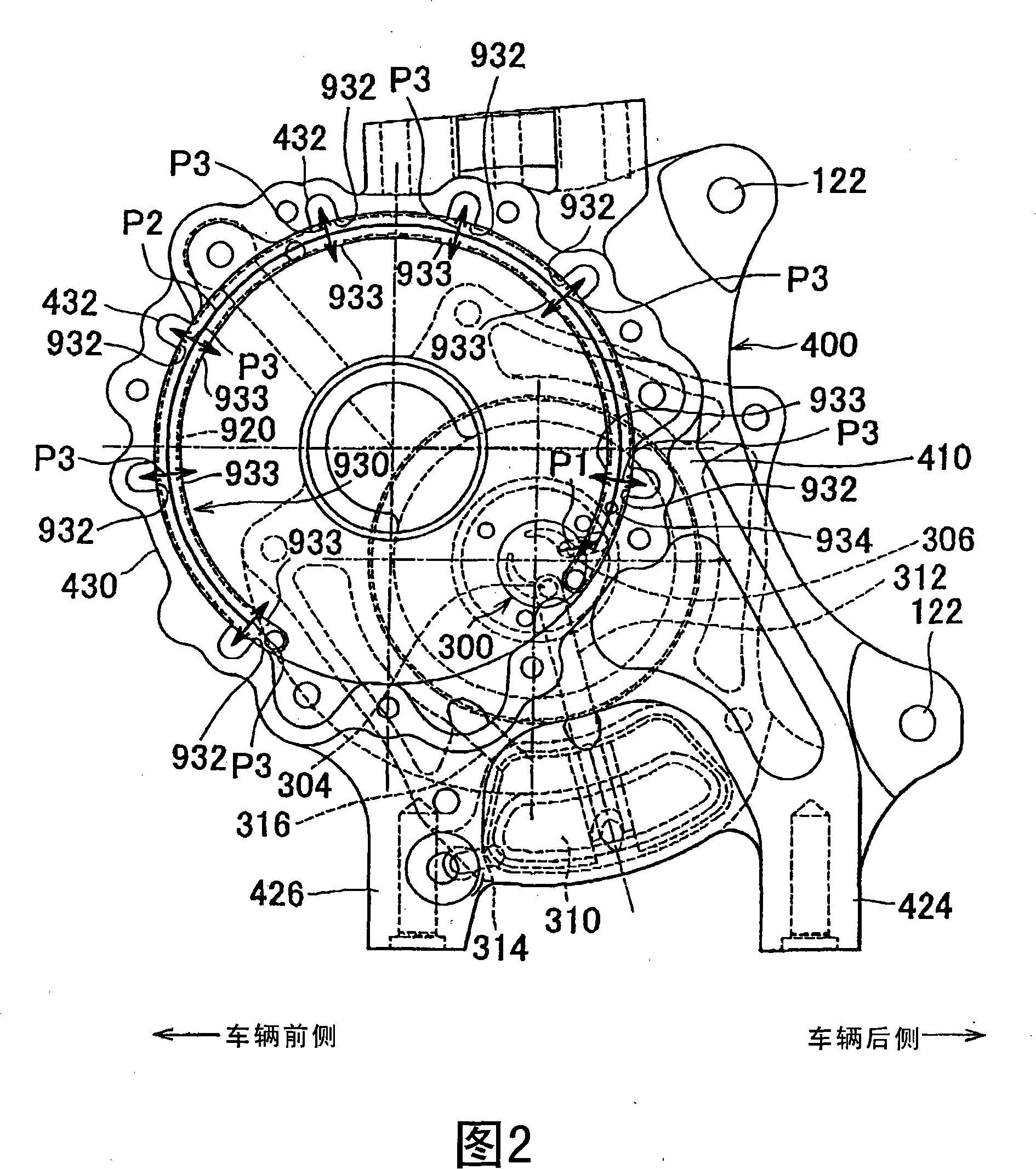

[0017] FIG. 1 is a sectional view of a main structure of a wheel assembly having an in-wheel motor according to an exemplary embodiment of the present invention. In this figure, the tire and the upper 1 / 3 portion of the wheel are omitted.

[0018] The wheel assembly 10 includes a wheel 14 on which tires (not shown) are mounted. As will be described in detail below, the main part of the constituent elements related to the motor is accommodated in a space surrounded by the inner peripheral surface 14 a of the rim of the wheel 14 . In the following description, the term “inside of the wheel assembly” refers to a substantially cylindrical space surrounded by the rim inner peripheral surface 14 a of the wheel 14 . However, expressions such as "a component is arranged within the wheel assembly" do not always express that the entire component is completely accommo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com