Cleaning device and method for cleaning the equipment joining with the same

A cleaning device and cleaning technology, which can be applied to cleaning methods using liquids, cleaning methods using gas flow, cleaning methods and utensils, etc., can solve problems such as long cleaning time, needle tip injury, and needle tip equipment blowing away.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

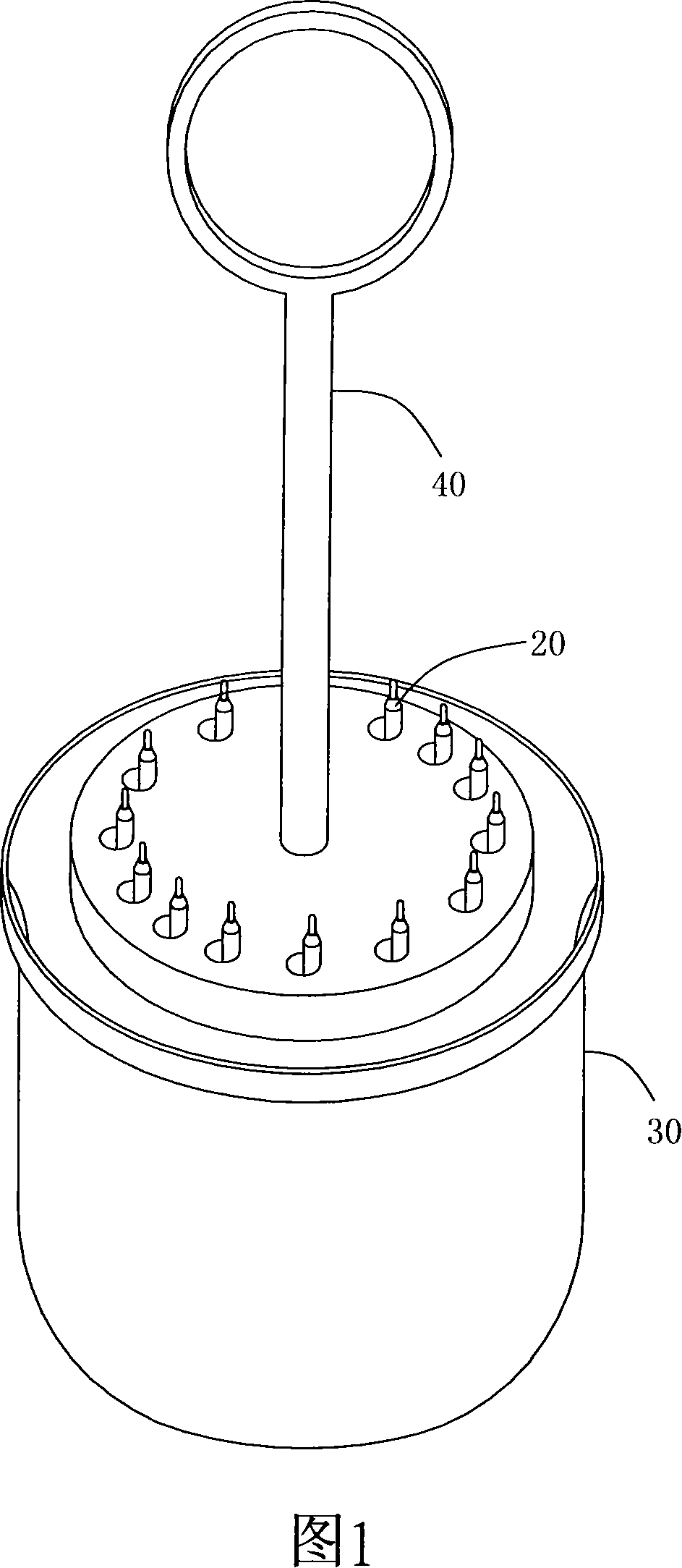

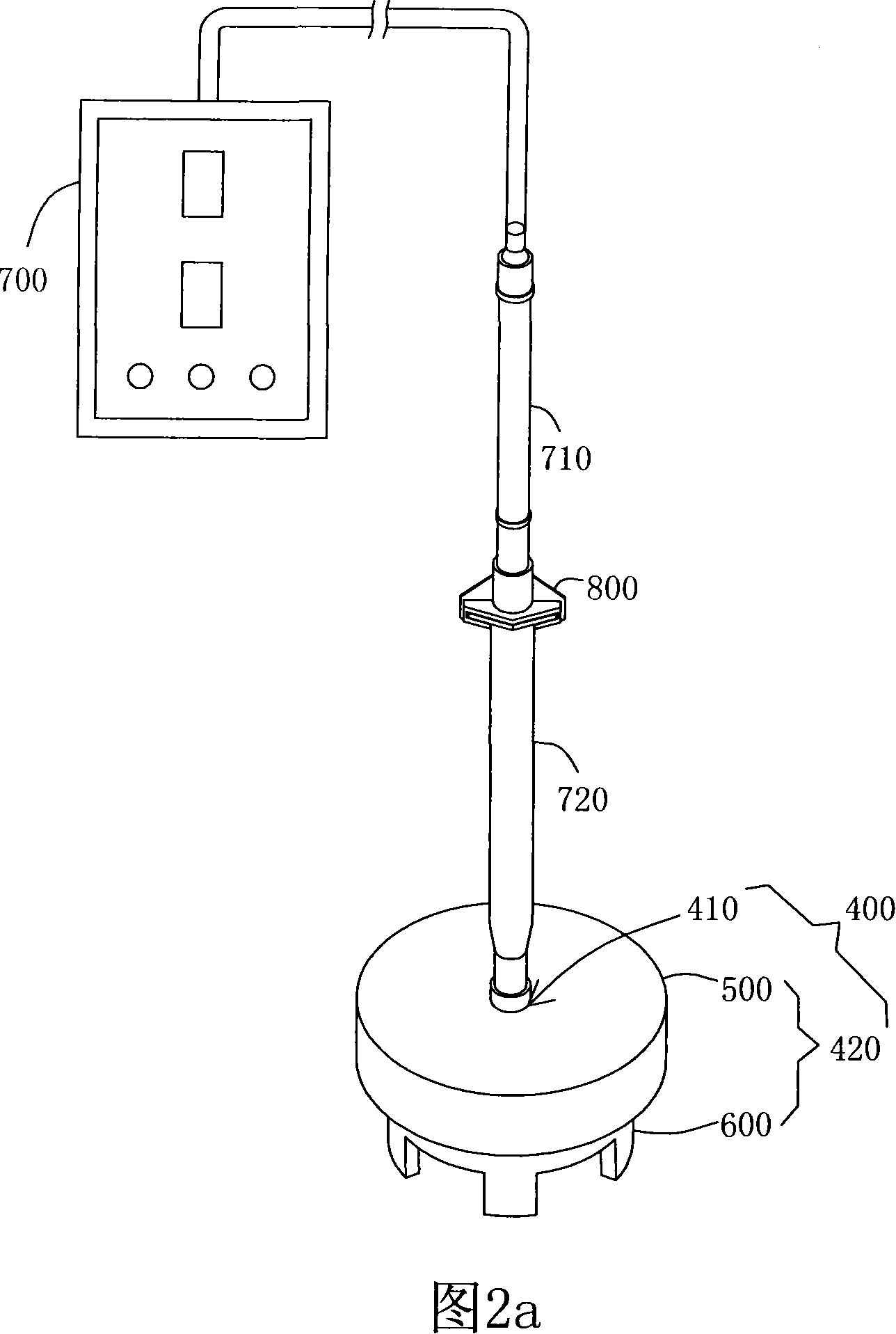

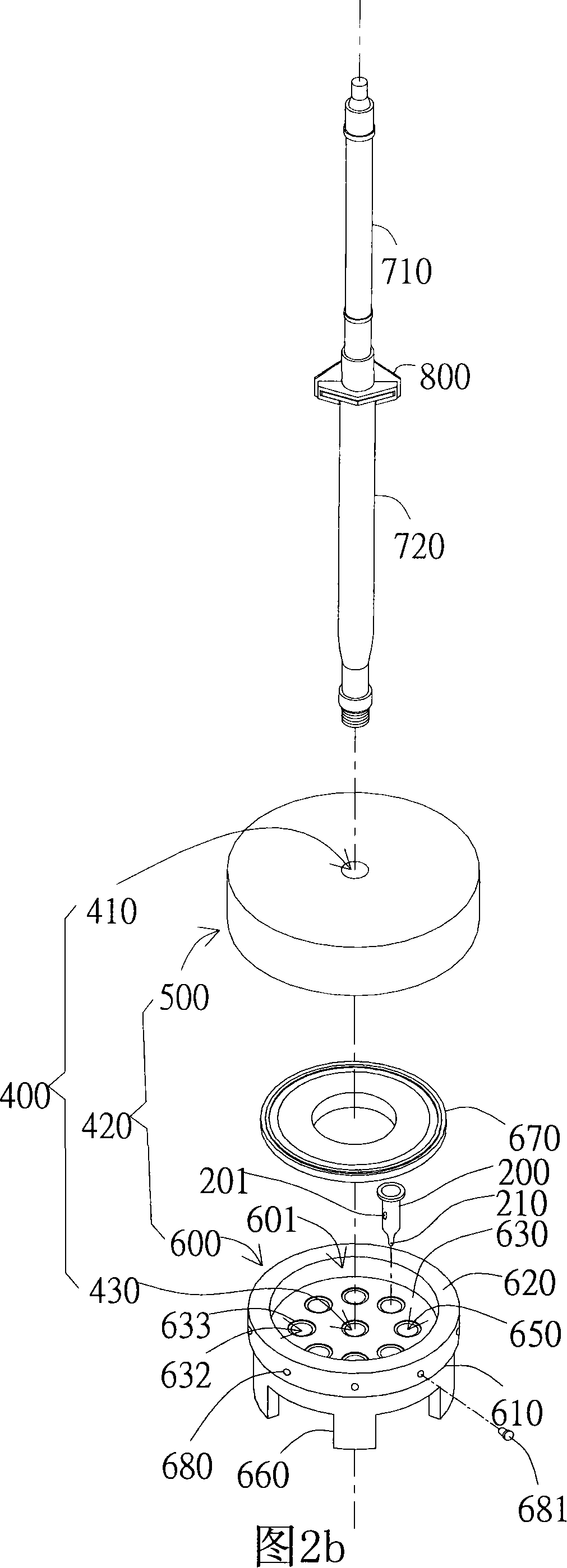

[0044] The invention provides a cleaning device and an equipment cleaning method combined with the device, which can accelerate the equipment cleaning effect and reduce equipment scrapping costs caused by careless cleaning operations. The cleaning device of the present invention and the equipment cleaning method combined with the device preferably use less solvent to clean objects to be cleaned, such as needle equipment, so as to achieve the maximum efficiency of solvent use. Here, the objects to be cleaned include but are not limited to the needle equipment used by the sealant coating machine in the panel assembly (Cell) process, such as needle equipment with a small aperture such as a wafer needle tester, or even the inner wall that is easy to accumulate residual materials Other equipment tools, such as oil spray nozzles or other coating nozzles (nozzles), etc., all have the possibility of being applicable to the cleaning device and equipment cleaning method of the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com