Wooden stair beam and method for making same

A manufacturing method and beam technology, applied in joists, girders, truss beams and other directions, can solve the problems of obvious stair beam sections, poor stair safety, affecting the beauty of stairs, etc. protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

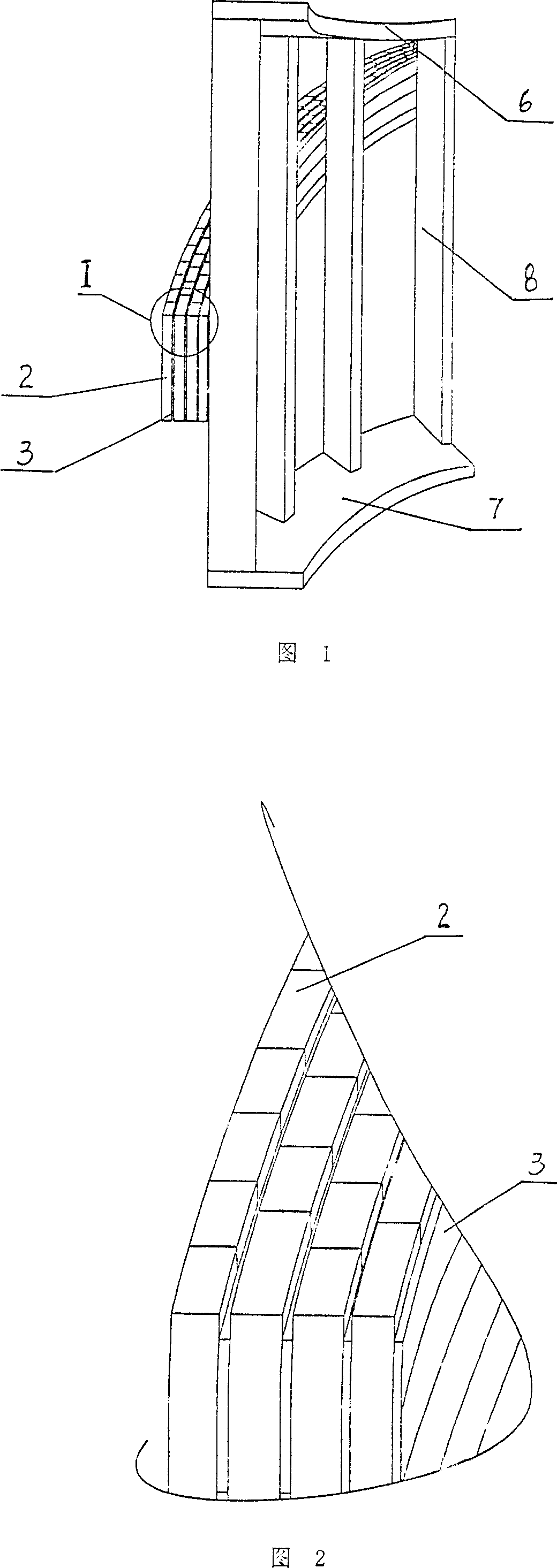

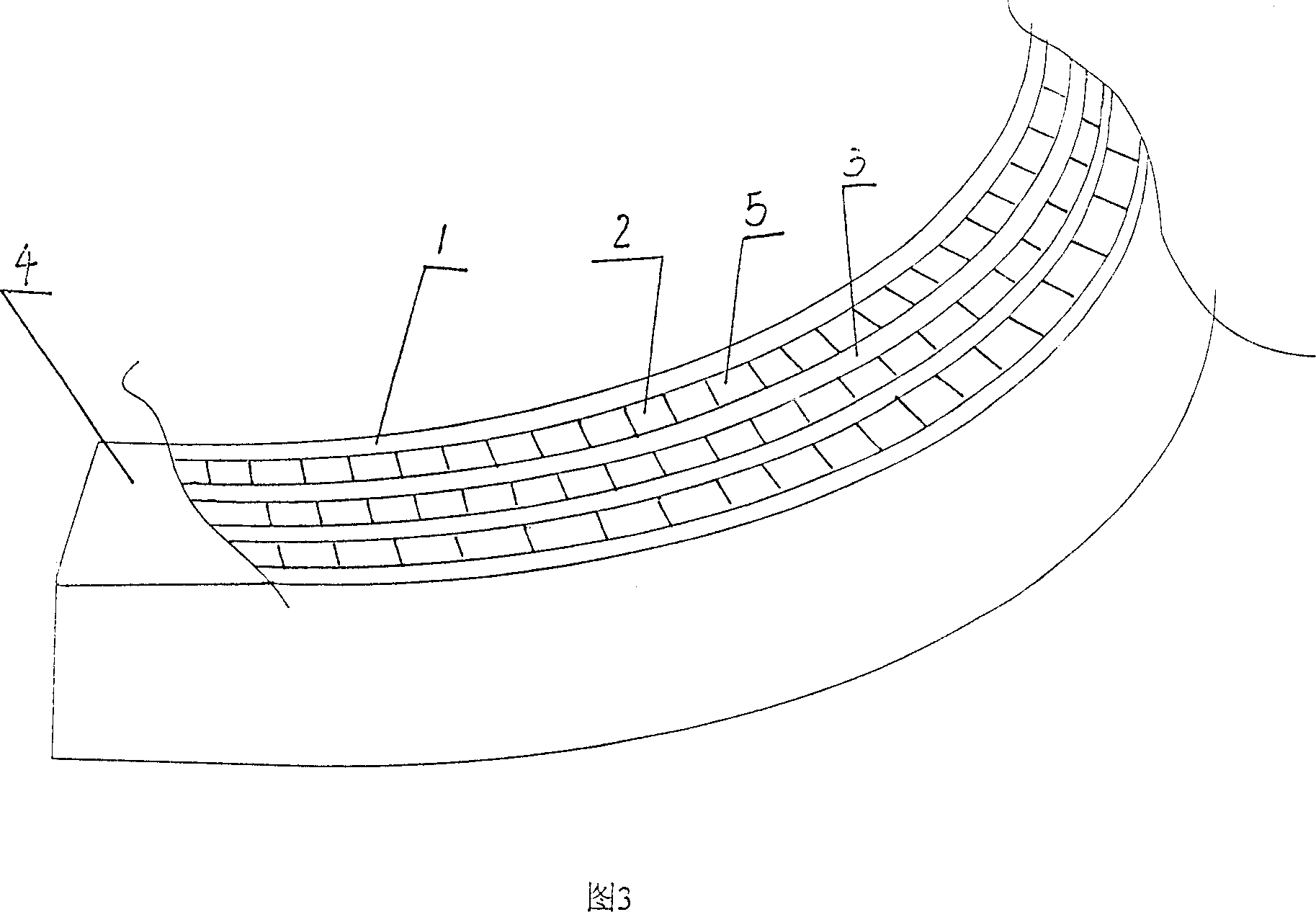

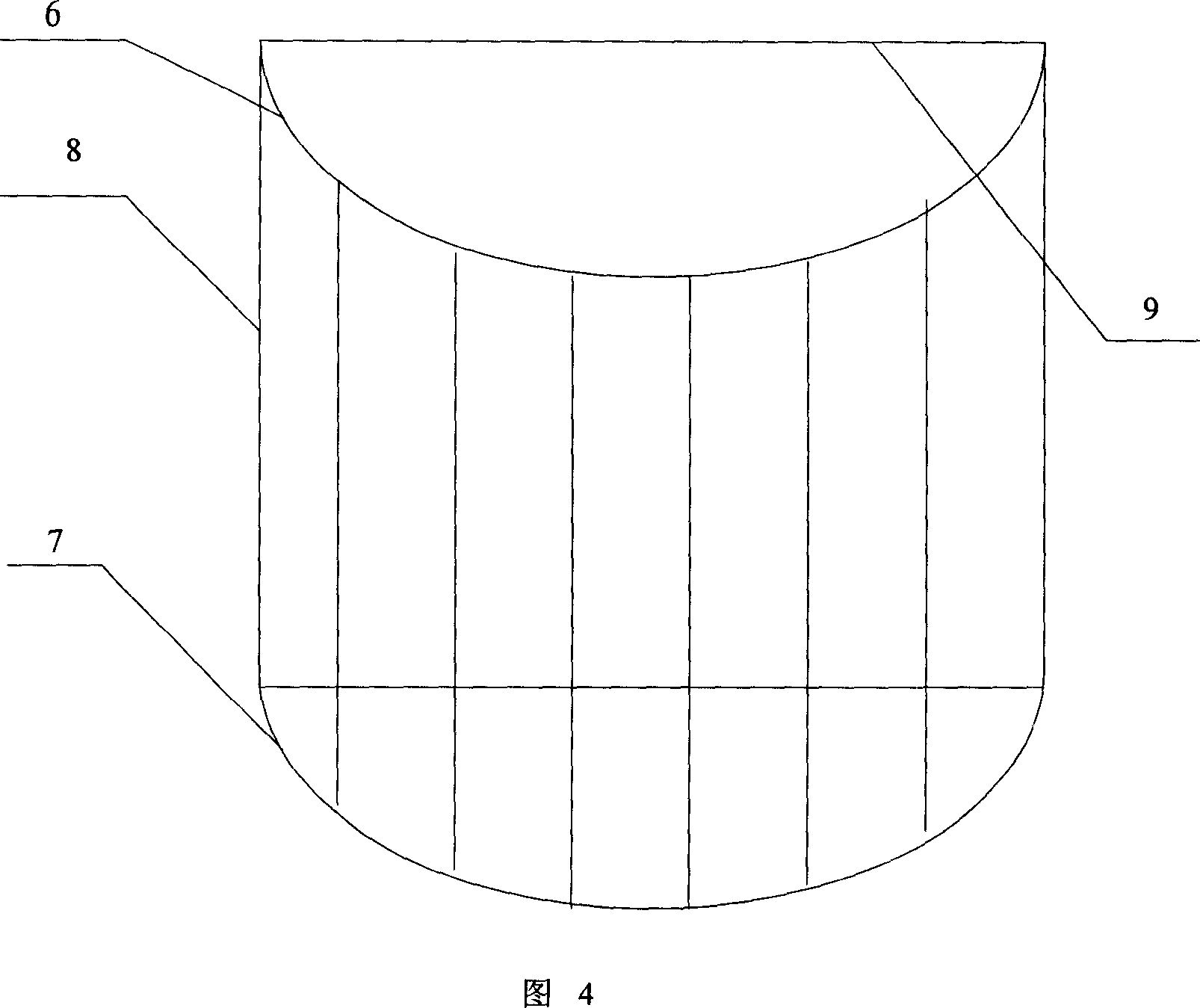

[0022] As shown in Fig. 1-4, a kind of wooden stair crossbeam of the present invention, it comprises crossbeam entity, and beam entity is arranged with wooden lath layer 3 at intervals in warp direction, and is provided with wood block dense layer between two adjacent wooden lath layers 2. The fibers of the slats in the slat layer and the fibers of the blocks in the dense layer of wood blocks are intersected in space. The wooden slat layer of the beam entity is composed of at least one wooden slat, and may also be composed of multiple slats. The wood block dense layer 2 of the beam entity is formed by a plurality of wood blocks 5 densely arranged in the weft direction. The wooden lath layer of the beam entity and the dense layer of wood blocks are connected as a whole through connectors and adhesives. The outer surface of the beam entity is covered with upper and lower sealing plates 4 and side sealing plates 1 . The manufacture method of the wooden stair beam of the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com