Method for limiting hydraulic brake with the maximum invoked break power

A technology of hydraulic brakes and braking power, applied in the directions of hydraulic brakes, hydraulic resistance brakes, brakes, etc., can solve problems such as limiting the availability of hydraulic brakes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

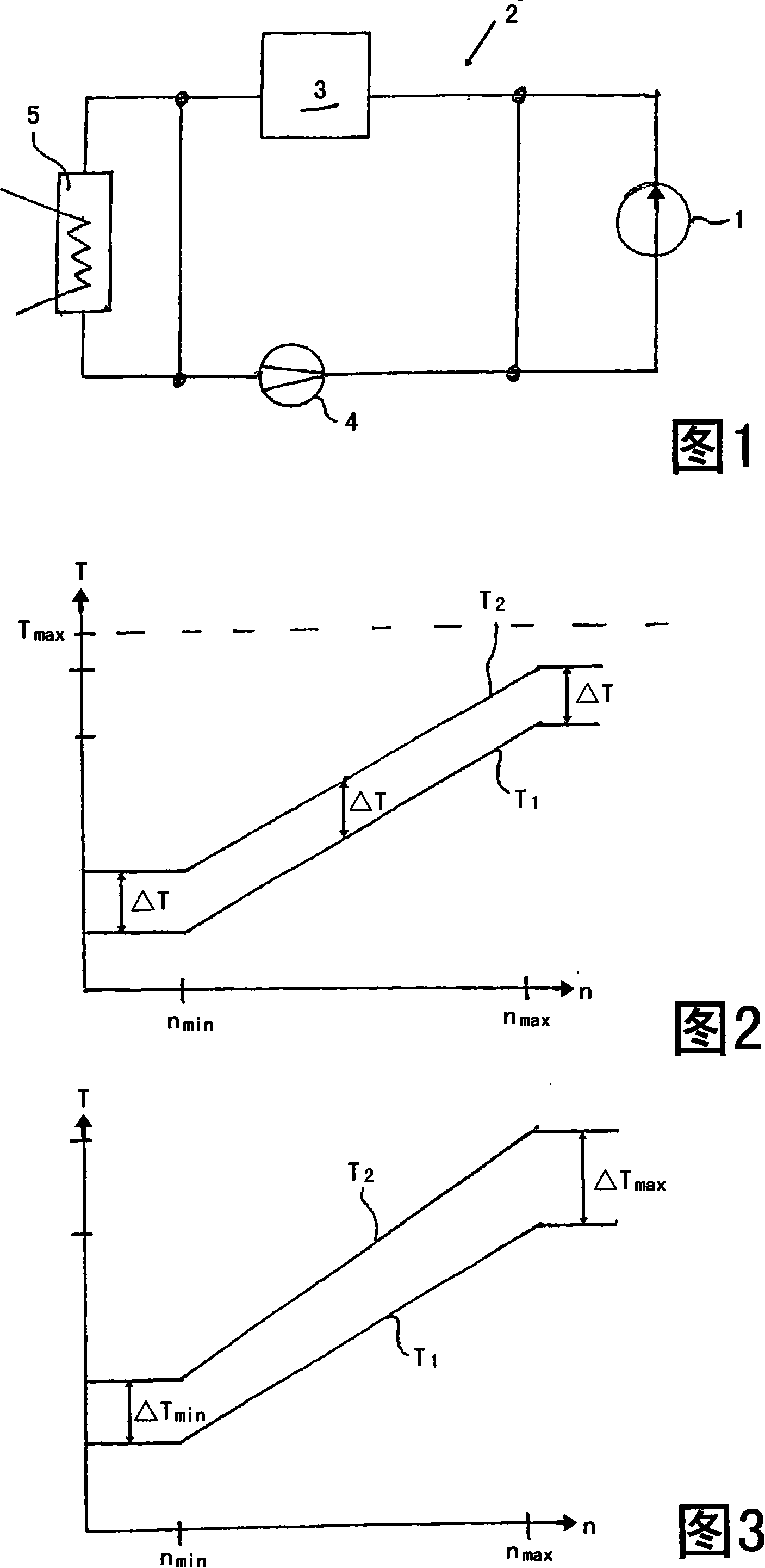

[0036] A schematic diagram of an engine cooling circuit 2 of a motor vehicle can be seen in FIG. 1 . In this engine cooling circuit 2, coolant is circulated in the circuit by means of a coolant pump 4, wherein the circuit passes through the vehicle radiator 5 (liquid-gas heat exchanger), in which the The heat is rejected to the surrounding environment. In addition, coolant flows through the vehicle drive engine 3 in order to cool the vehicle drive engine, and this coolant is the working fluid of the hydraulic brake 1 arranged in the engine cooling circuit 2 .

[0037] The arrangement of the different components in the engine cooling circuit 2 is arbitrarily selected in FIG. 1 and can be designed in different ways.

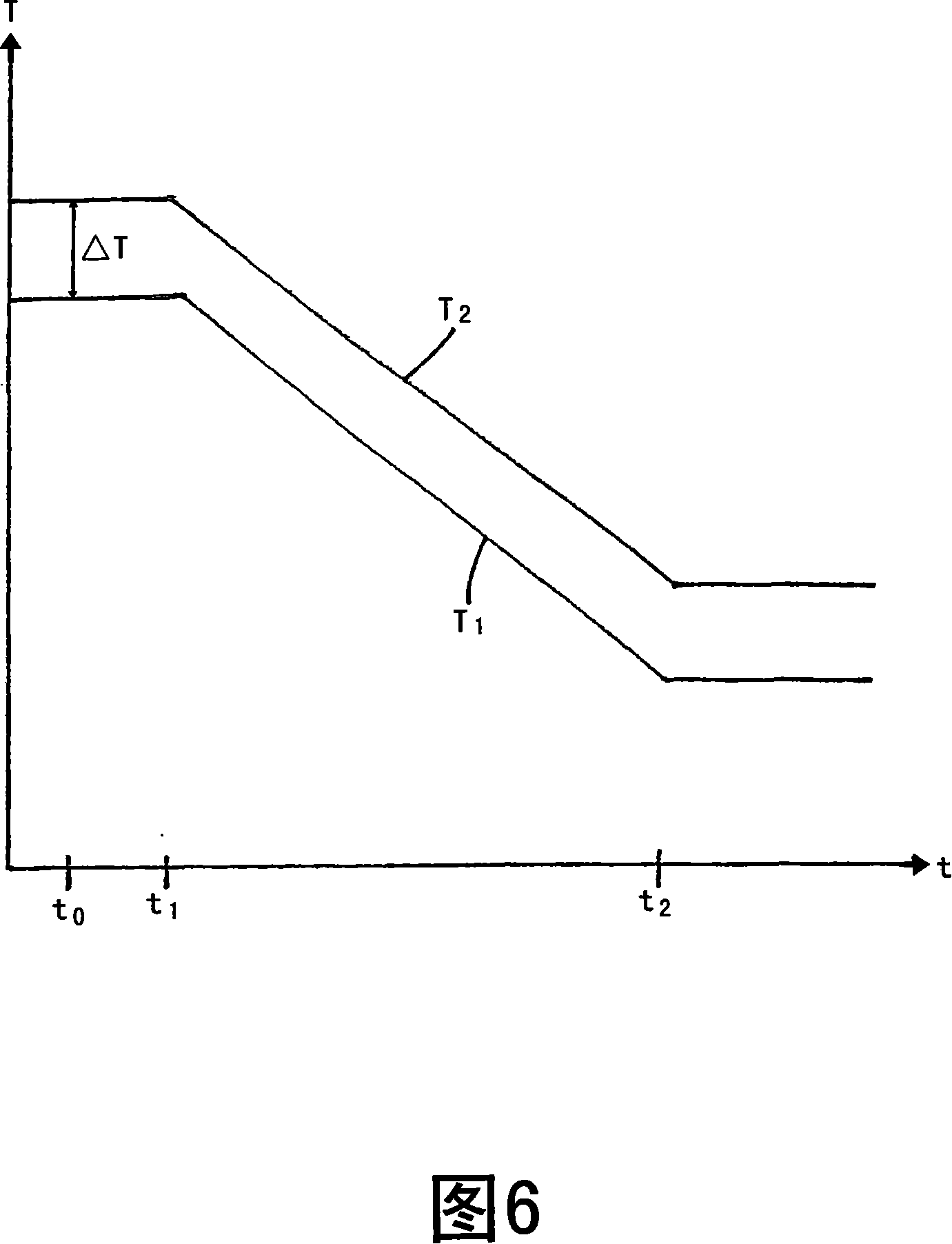

[0038] Graphs can be seen in FIGS. 2 to 5 which correspond directly to the rotational speed n of the motor vehicle's drive engine exactly two temperature curves. The two temperature curves are each in the form of a straight line with a constant slope in the rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com