Metalloid cooker for electromagentic furnace

A non-metallic and induction cooker technology, applied in home appliances, kitchen appliances, applications, etc., can solve problems such as complicated operation, inability to heat non-metallic cookers, and inability to achieve precise control, so as to reduce the interference of thinking factors and facilitate operation , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

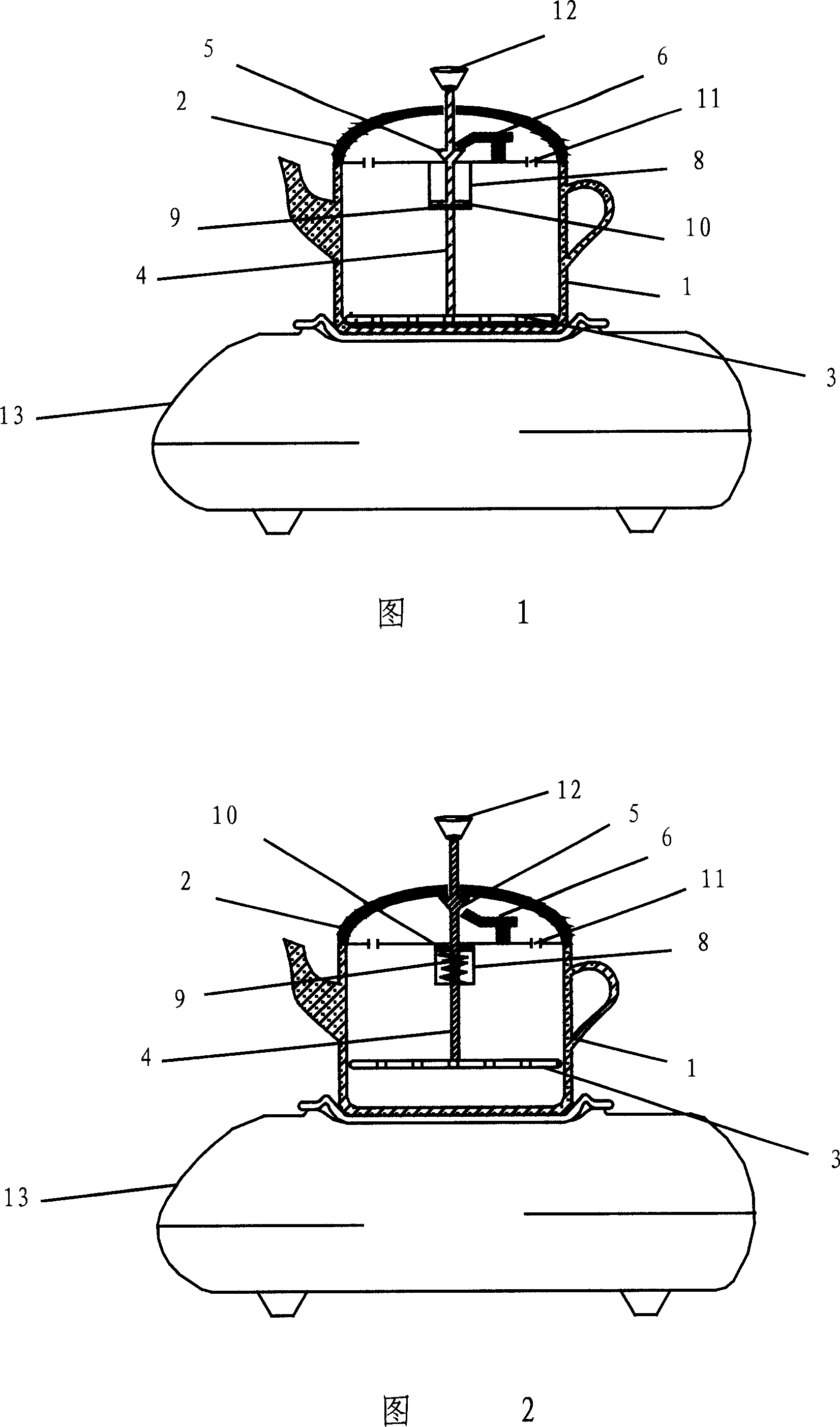

[0019] Embodiment 1: As shown in Fig. 1 and 2, a kind of non-metallic cooking utensils for induction cooker, comprises non-metallic container 1 and the magnetic conduction heater 3 that is arranged in this container, is provided with hollow on the top of non-metallic container 1 Cover 2, the bottom of the cover 2 is provided with a spring chamber 8 with a built-in compression spring 9, and the magnetically conductive heating body 3 is provided with a central axis 4 passing through the spring chamber 8 and extending out of the cover 2. The central axis 4 is provided with a compression spring plate 10, and the compression spring 9 is located between the compression spring plate 10 and the bottom of the spring storehouse 8; There is a bimetal locator matched with the fixed pin 5, the locator is a bimetal 6 fixed at the inner bottom of the cover 2, the other end of the bimetal 6 can be stuck on the fixed pin 5, and the cover 2 A steam guide hole 11 communicating with the inner cav...

Embodiment 2

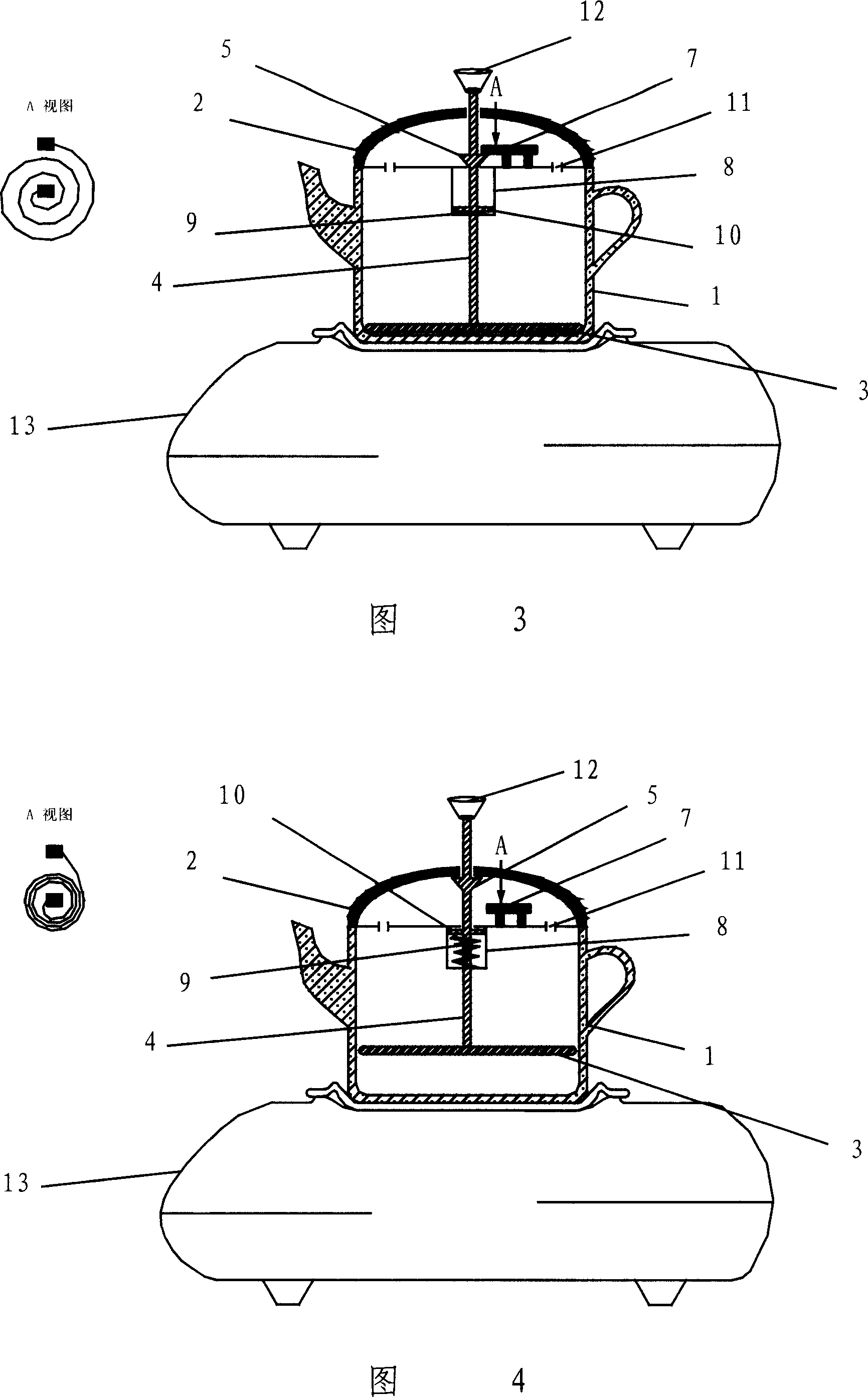

[0022] Embodiment 2: As shown in Fig. 3 and 4, a kind of non-metallic cooking utensils that is used for induction cooker, comprises non-metallic container 1 and the magnetic conduction heater 3 that is arranged in this container, is provided with hollow on the top of non-metallic container 1 Cover 2, the bottom of the cover 2 is provided with a spring chamber 8 with a built-in compression spring 9, and the magnetically conductive heating body 3 is provided with a central axis 4 passing through the spring chamber 8 and extending out of the cover 2. The central axis 4 is provided with a compression spring plate 10, and the compression spring 9 is located between the compression spring plate 10 and the bottom of the spring storehouse 8; There is a bimetallic locator that cooperates with the fixed pin 5, and the locator is a bimetallic coil spring 7 fixed at the inner bottom of the cover body 2 at both ends. Above, the cover body 2 is provided with a steam guide hole 11 communicat...

Embodiment 3

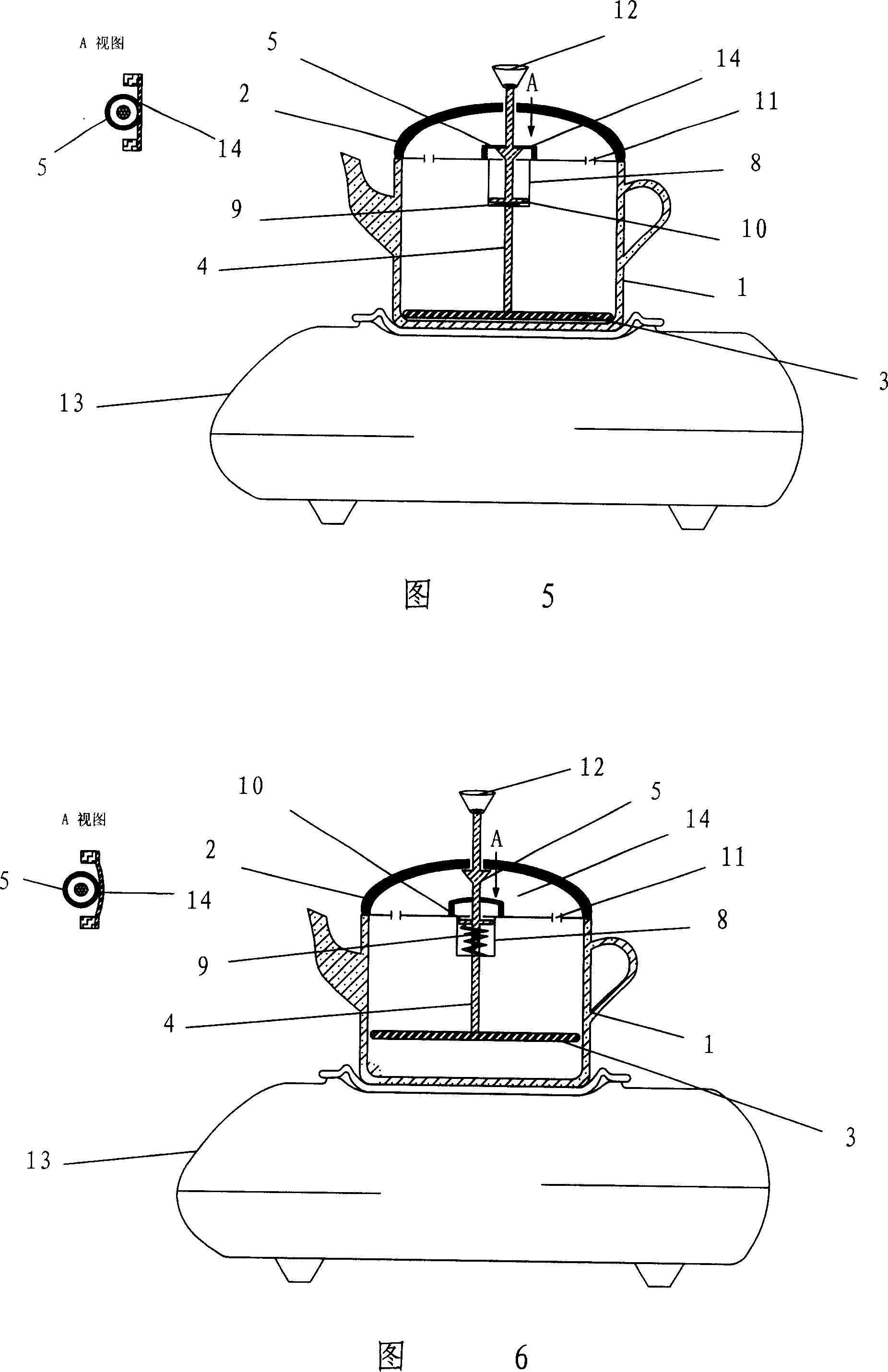

[0025] Embodiment 3: As shown in Figures 5 and 6, a non-metallic cooker for an induction cooker includes a non-metallic container 1 and a magnetically conductive heating body 3 arranged in the container, and a hollow Cover 2, the bottom of the cover 2 is provided with a spring chamber 8 with a built-in compression spring 9, and the magnetically conductive heating body 3 is provided with a central axis 4 passing through the spring chamber 8 and extending out of the cover 2. The central axis 4 is provided with a compression spring plate 10, and the compression spring 9 is located between the compression spring plate 10 and the bottom of the spring storehouse 8; There is a bimetal locator matched with the fixed pin 5, the locator is a bimetal curved piece 14 whose two ends are fixed on the inner bottom of the cover body 2, the body of the bimetal curved piece 14 can be stuck on the fixed pin 5, and the cover The body 2 is provided with a steam guide hole 11 communicating with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com