Cleaning article, method of fluffing cleaning article, and method of producing cleaning article

An article and handle technology, which is applied in the field of cleaning articles, can solve the problems of insufficient consideration of convenience, ineffective cleaning of fiber bundles, and poor cleaning performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

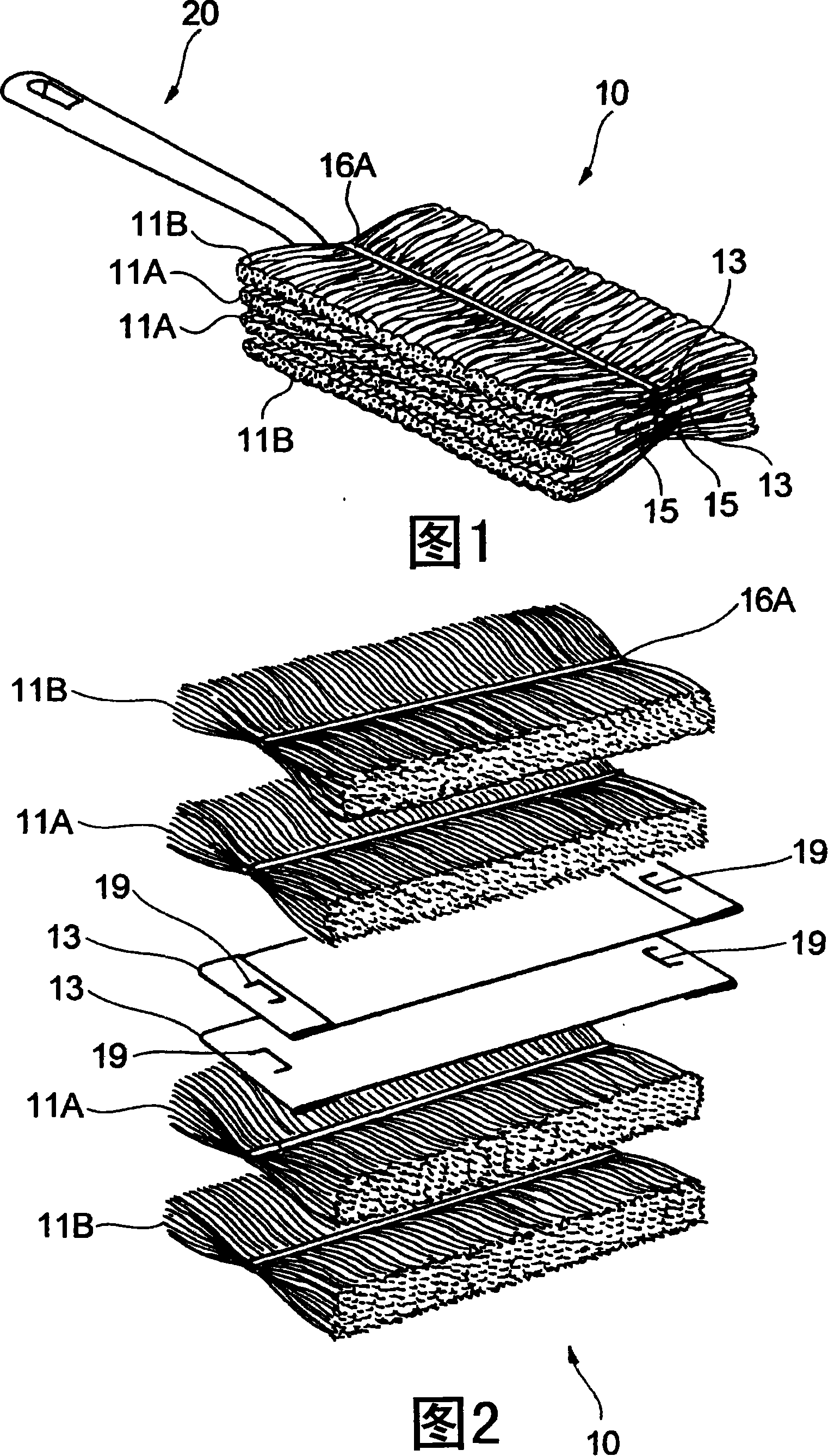

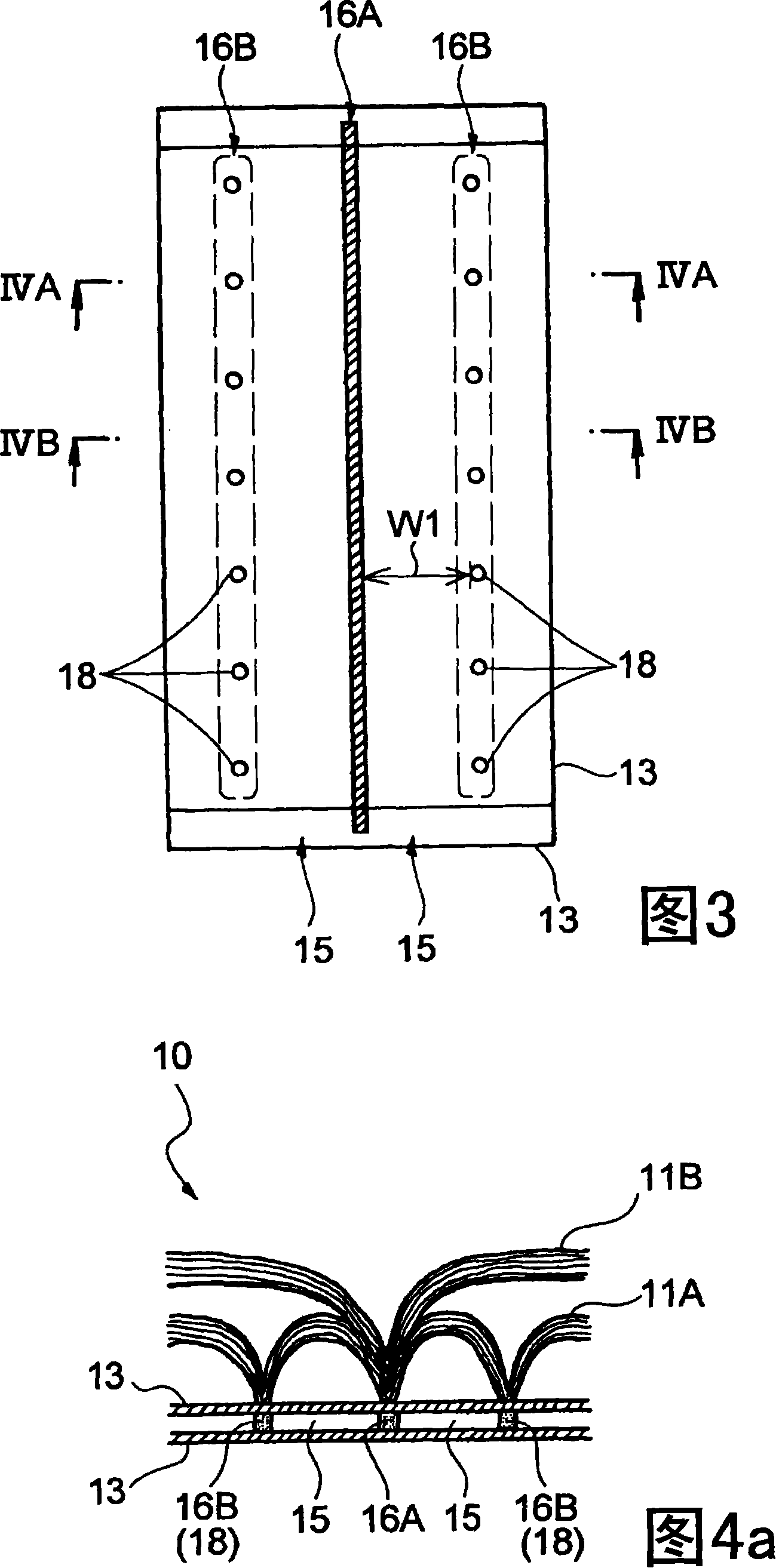

[0049] Hereinafter, the cleaning article of the present invention will be described with reference to the drawings based on the first embodiment which is a preferred embodiment thereof.

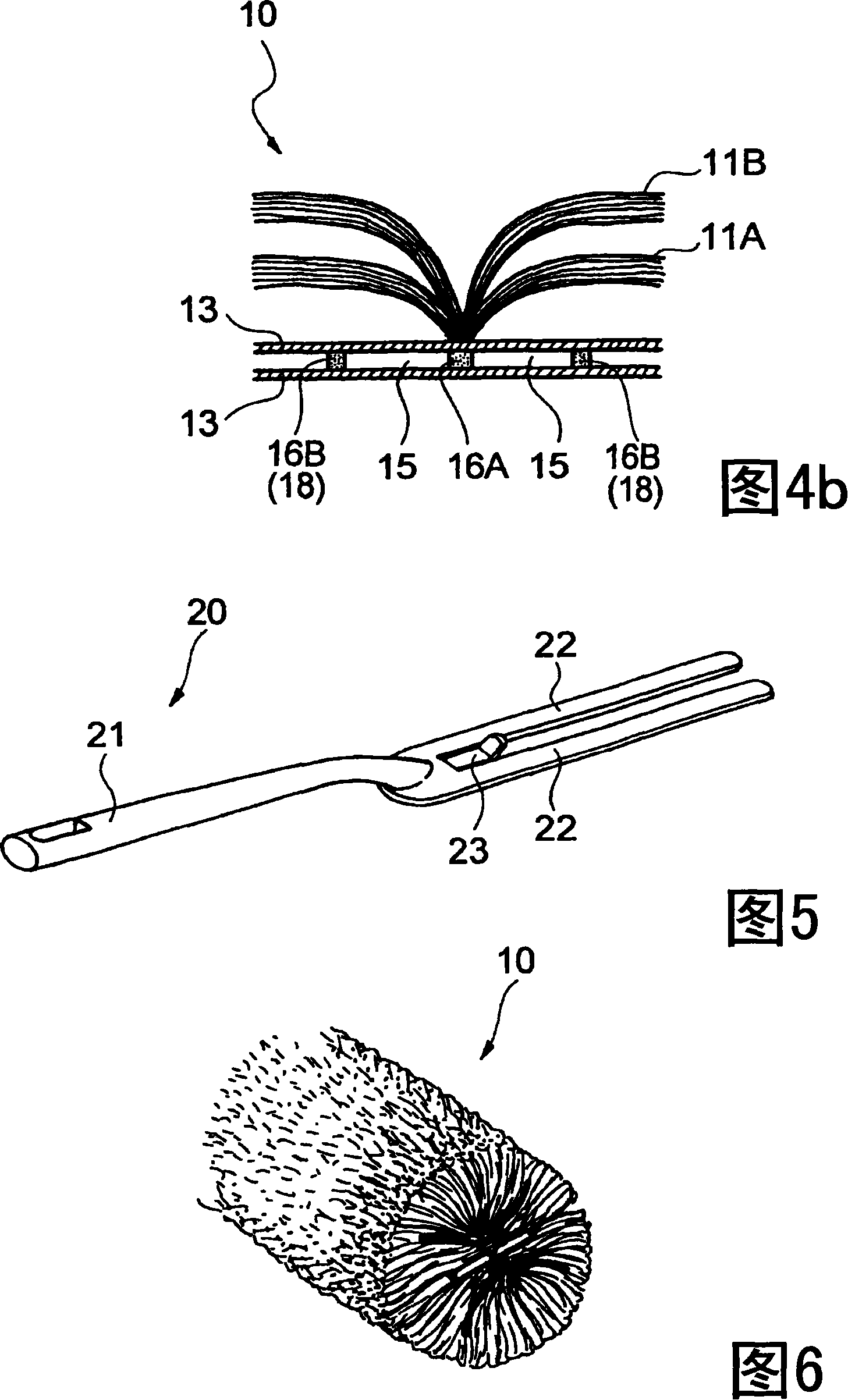

[0050] As shown in FIGS. 1 to 4( b ), the cleaning article 10 according to the first embodiment has a vertically long flat shape as a whole, and includes a pair of flat cylindrical handle insertion portions 15 , 15 in the width direction. In the cleaning article 10 according to this embodiment, a pair of insertion portions 22 , 22 to which a handle 20 is attached can be inserted into the pair of handle insertion portions 15 , 15 (details will be described later).

[0051] In addition, in the following description, "longitudinal direction" and "width direction" refer to the longitudinal direction (insertion direction) and the width direction of the handle insertion part 15, unless otherwise specified.

[0052]The handle insertion portion 15 is formed by joining two opposing handle insertion po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com