Device and method for pumping and filtering air containing dust and/or fibre on the spinning machine

A technology for textile machines and equipment, applied in the field of equipment and methods for suctioning and filtering air containing dust and/or fibers on textile machines, capable of solving problems such as increased energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

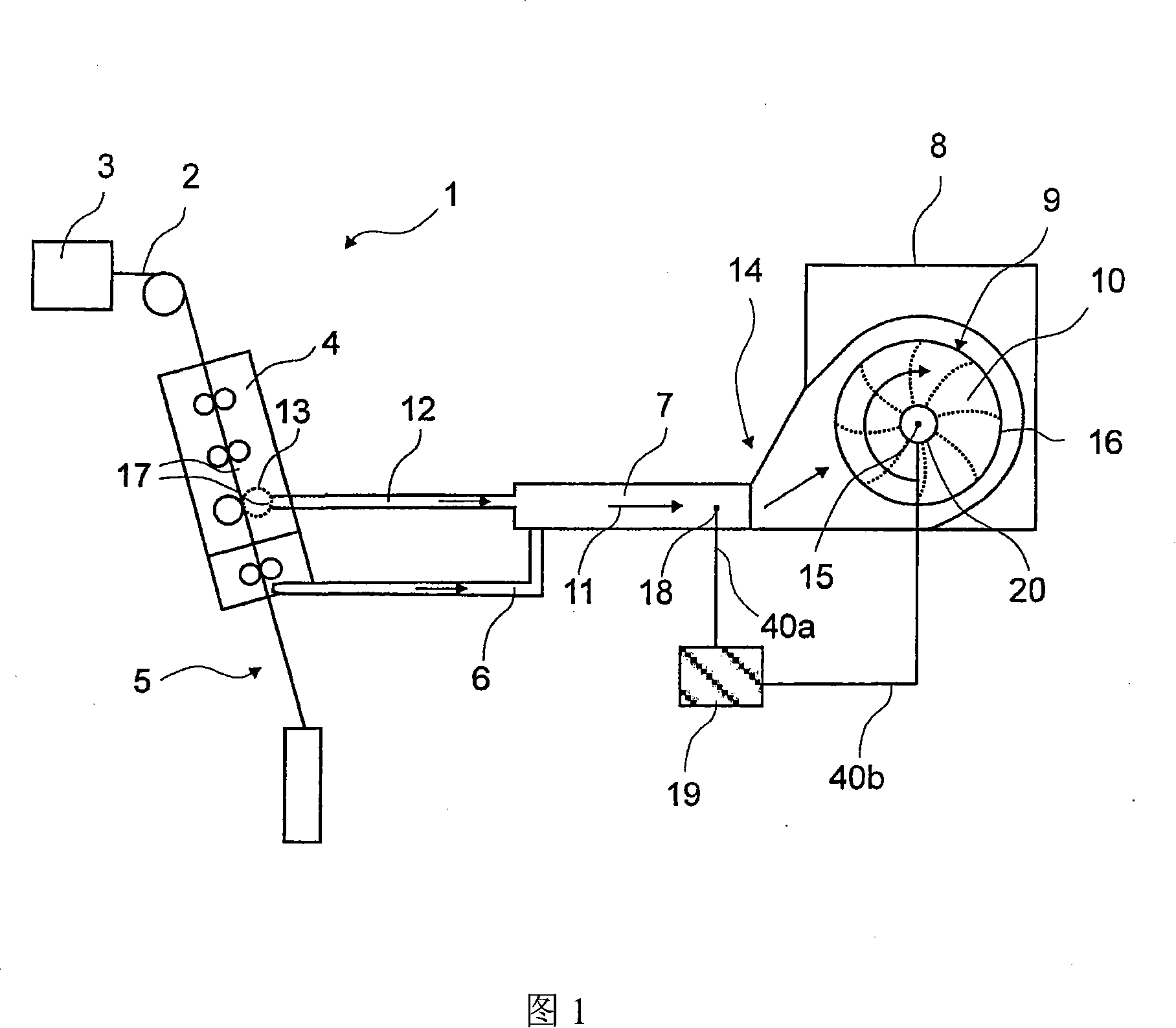

[0066] In FIG. 1 , a suction and filter device 14 follows the textile machine 1 , in particular the spinning machine, and is shown here only schematically. In this figure, the yarn 2 is conveyed from the roving bobbin 3 to the drafting device 4 with the pneumatic compacting unit 13, where it is drafted, compacted and then conveyed to the spinning station 5 in particular is on the spindle. A suction line 6 is provided between the drafting device 4 and the collecting unit 13 , which leads to the channel 7 . The suction at the collecting unit 13 is generated by the suction duct 12 which also leads to the channel 7 . The flow direction of the extracted air to be filtered is indicated by arrow 11 .

[0067] At least one suction pipe 6 and / or one suction pipe 12 is arranged at each spinning station 5 or between each spinning station 5 and the drafting device 4, wherein a plurality of pipes can pass through To a common channel 7 or multiple channels 7. The suction pipes 6 , 12 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com